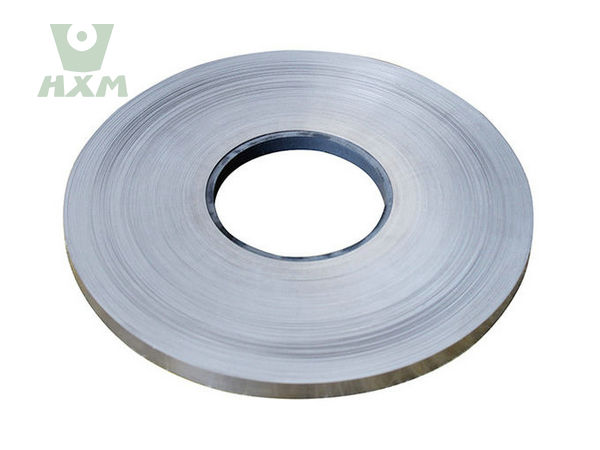

Precision Alloy Strip, please note that the above table provides a range of standard thicknesses, widths, and lengths for Precision Alloy.

- Dimensions:

- Thickness: 1 mm -150 mm

- Width: <600mm

- Certification: ISO, SGS, BV and so on.

- *Customized size needs to be confirmed with us

- Grades: 1J22 soft magnetic alloy, 1J50 soft magnetic alloy, 1J79 Permalloy, 1J85 Permalloy, 4J32(Super-Invar), 4J36, 4J29 Kovar alloy, 4J42Kovar alloy, Cobalt-based elastic alloy 3J21, 6026, 6J22, 50HXC.

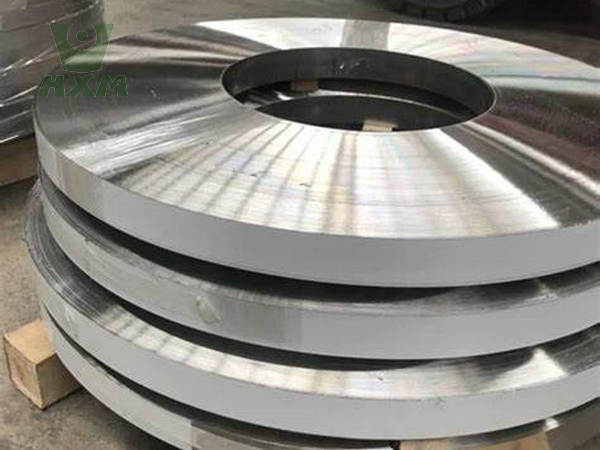

Precision Alloy Strip Size And Specifications

Huaxiao Metal Supplier provides all sizes of Precision alloy strip for sale. Customized specifications are available upon request. Additionally, the exact chemical composition and mechanical properties may vary slightly within the ranges listed, depending on the specific alloy formulation and production process. Custom sizes are also available upon request. Welcome to inquire, and learn about more details about the alloy strip.

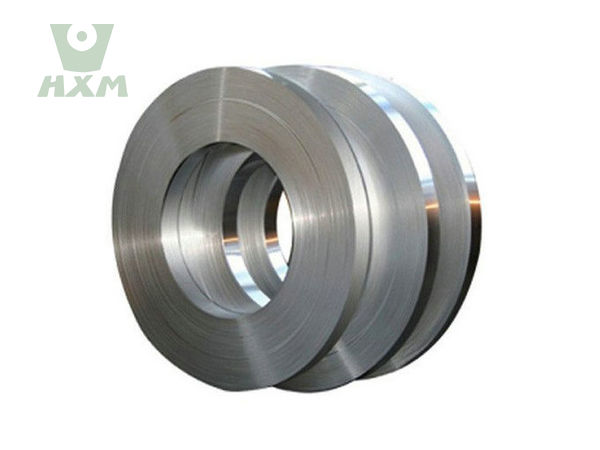

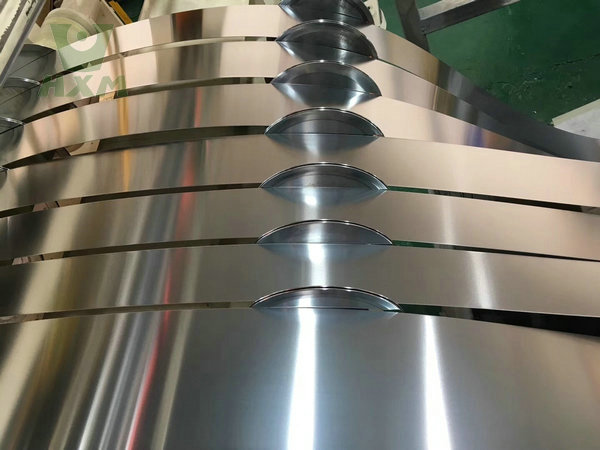

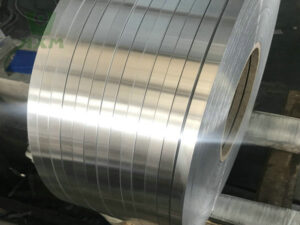

Precision alloy strips are thin, flat-rolled metal products engineered for exact dimensional tolerances, superior surface finishes, and specialized material properties. These strips are widely used in electronics, aerospace, medical devices, and industrial applications where precision and performance are critical.

| Alloy Number | Dimensions (mm) | Chemical Composition (%) | Mechanical Properties |

|---|---|---|---|

| 6J22 | Thickness: 0.1~2, Width: Customized | Ni: Balance, Cr: 1921, Al: 2.53.5, Fe: ≤1.5 | High resistivity, low temperature coefficient of resistivity, excellent oxidation resistance |

| 6026 | Thickness & Width: Customized | Al: Balance, Si: ≤0.4, Cu: ≤0.1, Mg: 4.0~4.9, Zn: ≤0.25, Mn: 0.4~1.0, Ti: ≤0.15, Cr: 0.05~0.25, Fe: ≤0.4 | Tensile Strength ≥270 MPa, Yield Strength ≥110 MPa, Elongation ≥20% |

| 50HXC | Thickness: 0.02~0.04, Width: Customized | Ni: 49.5~61, Si: 3.8~4.2, Cr: 1.1~1.4, Balance: Fe & Trace Elements | Moderate strength, high permeability, suitable for pulse transformer cores |

| Kovar (4J29) | Thickness: 0.15~4, Width: ≤200 | Ni: 29, Co: 17, Fe: Balance (primary element), with trace amounts of Cr, Si, Mn, etc. | Density: 8.17g/cm³, Melting Point: 1450℃, Suitable for glass sealing in electronic vacuum devices |

Please note that the above specifications are typical and may vary slightly based on the manufacturer, production batch, and specific application requirements. For precise specifications and availability, it is recommended to consult with a supplier or manufacturer of Precision alloy strips. Huaxiao Metal Manufacturer also provides other shapes of Precision products, such as bar, sheet&plate, coil, tube&pipe, wire&mesh. The price is affordable and suitable.

Comparison with Standard Metal Strips

| Feature | Precision Alloy Strips | Commercial Strips |

|---|---|---|

| Tolerance | ±0.001 mm | ±0.05 mm |

| Surface Finish | Mirror (Ra < 0.1 µm) | Rough (Ra > 0.8 µm) |

| Material Control | Certified melt reports | Generic composition |

| Cost | Higher (quality premium) | Lower |

Industries Requiring Precision Strips:

✔ Electronics (PCBs, shunts)

✔ Medical (implants, surgical tools)

✔ Aerospace (seals, sensors)

✔ Energy (battery foils, fuel cells)

What are the Benefits?

Precision alloy strips offer a multitude of benefits due to their unique physical and mechanical properties. Precision alloy strips offer a combination of unique physical and mechanical properties, versatility in applications, and cost-effectiveness that make them an invaluable material for a wide range of industries and applications. This can significantly reduce the time-to-market for new products and enhance overall production efficiency. Welcome to Huaxiao Metal Manufacturer to request the price, trust you can be satisfied in the alloy products and buy our products in quickly.

Precision Alloy Strip Applications and Uses

Huaxiao Metal Supplier provides all kinds of precision alloy coil in the world. Welcome to inquiry and ask for the price.

Electronics and Electrical Engineering

- Resistors and Heaters: Alloys with specific electrical resistivity and thermal conductivity are used in resistors and heaters. These strips can be tailored to provide precise temperature control and electrical performance.

Aerospace and Defense

- Sensors and Actuators: Precision alloy strips are used in sensors and actuators that require high precision and reliability. Their ability to undergo reversible deformation under certain stress or temperature conditions makes them suitable for these applications.

- Propulsion Systems: Specific alloys are used in propulsion systems, such as aircraft engines, due to their high strength, toughness, and corrosion resistance.

Automotive Industry

- Transmission Systems: Precision alloy strips are used in automotive transmission systems to provide stable and reliable performance. They can withstand high mechanical loads and temperatures, ensuring smooth gear shifts and optimal vehicle performance.

- Exhaust Systems: Alloys with high temperature stability are used in exhaust systems to withstand the high temperatures generated by the engine.

Precision Alloy Strip Advantages

Unique Physical Properties

- Excellent Magnetic Properties:

- Some precision alloy strips, such as soft magnetic alloys, exhibit high permeability and low coercivity, making them ideal for applications requiring magnetic components and devices.

- Hard magnetic alloys (permanent magnets) have high coercivity and are suitable for applications where magnetic fields need to be maintained without external power.

- Thermal Properties:

- Precision alloy strips with specific thermal expansion coefficients can be used in temperature sensors, optical instruments, and other precision devices.

- Some alloys can maintain stable physical and chemical properties at high temperatures, making them suitable for use in harsh environments.

Superior Mechanical Properties

- High Strength and Toughness:

- Precision alloy strips typically have good strength and toughness at room temperature, allowing them to withstand various complex engineering environments.

- This makes them suitable for applications requiring high mechanical loads and durability.

- Elastic Recovery and Corrosion Resistance:

- Elastic alloys can undergo reversible deformation under certain stress or temperature conditions, making them ideal for springs, washers, and sensors.

- Many precision alloy strips also exhibit excellent corrosion resistance, enabling them to operate stably in harsh environments such as strong acids and bases.

Versatile Applications

- Wide Range of Applications:

- Due to their unique properties, precision alloy strips are widely used in various fields, including electrical engineering, aerospace, automotive, energy and chemicals, and medical devices.

- For example, they are used in transformers, induction coils, aircraft engines, automotive transmission systems, nuclear reactors, and orthopedic implants.

- Customization and Flexibility:

- Precision alloy strips can be customized in terms of dimensions, chemical composition, and mechanical properties to meet specific application requirements.

- This flexibility allows for the creation of tailored solutions for a wide range of industries and applications.

Cost-Effectiveness and Efficiency

- Material Efficiency:

- Precision alloy strips are often produced with high material utilization rates, minimizing waste and reducing production costs.

- This contributes to a more sustainable and environmentally friendly manufacturing process.

- Short Lead Times:

- The production of precision alloy strips can be relatively fast compared to traditional manufacturing methods, allowing for quicker prototyping and testing of new designs.

- Material Efficiency:

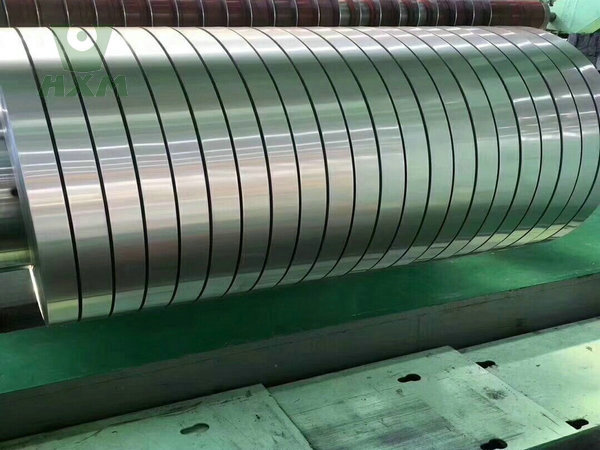

Alloy Factory

Huaxiao Metal Supplier provides professional services and reasonable prices, offering customers the best quality products. The Precision Alloy Strip Alloy Factory is a specialized manufacturing facility dedicated to the production of high-quality precision alloy coils. This factory combines advanced technology, rigorous quality control, and experienced personnel to ensure the production of precision alloy strips that meet the highest standards.The factory is equipped with state-of-the-art production equipment and machinery, capable of producing precision alloy coils with precise dimensions and consistent quality. Welcome to require, and ask to the price.

You ask, we answer

We can provide small precision alloy strip samples for you to check the quality. The sample is free, you only need to pay the shipping cost.

Precision alloy and titanium differ in composition, properties, and applications. Precision alloy is a specialized type of alloy material with various physical properties tailored for specific applications, while titanium is a lightweight, strong, corrosion-resistant metal widely used in aerospace, medical, and marine applications.

Precision alloy is a type of specialty alloy material that is engineered to exhibit precise and predictable physical properties. These alloys are designed for applications that require tight control over certain characteristics, such as magnetic, electrical, thermal, or mechanical properties.

Arabic

Arabic Dutch

Dutch English

English French

French German

German Italian

Italian Japanese

Japanese Korean

Korean Portuguese

Portuguese Romanian

Romanian Russian

Russian Spanish

Spanish