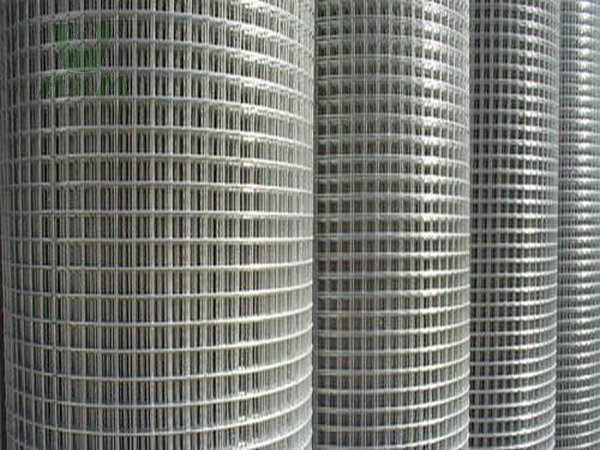

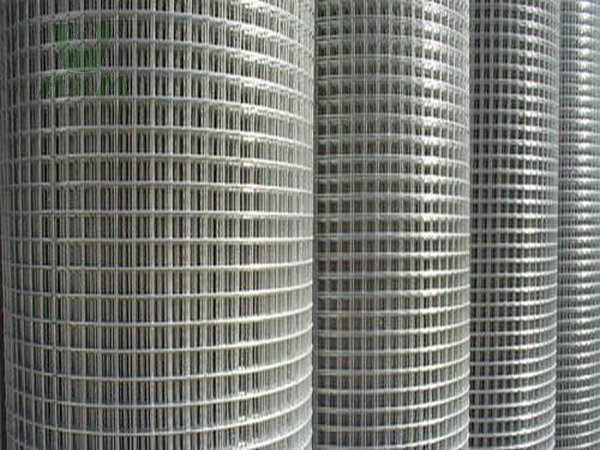

Monel 400 Wire Mesh, please note that the above table provides a range of standard diameter and lengths for Monel.

- Dimensions:

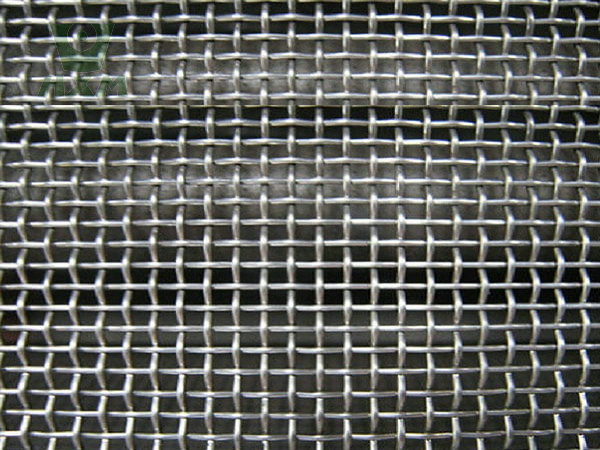

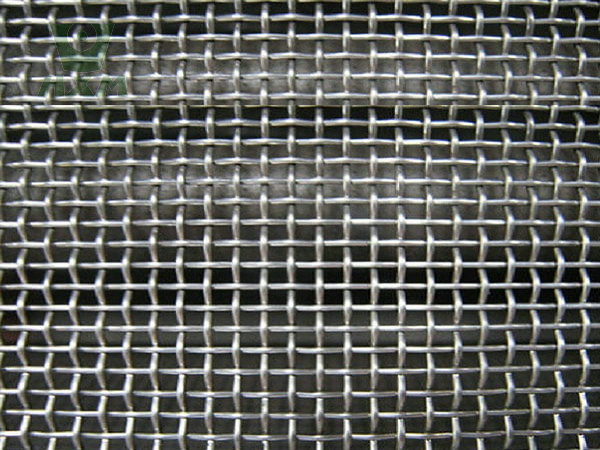

- Mesh Size: 0.2mesh/inch to 300mesh/inch

- Wire Diameter: 0.03mm to 8.0mm

- Certification: ISO, SGS, BV and so on.

*Customized size needs to be confirmed with us

- Grades: 400, 401,404, R-405, K-500, 502.

- Payment Term:L/C at sight, T/T, West Union

- Delivery Time: Future goods: Also 30 Work days, Ready Stock:7-15 days.

Monel 400 is a nickel-copper alloy known for its exceptional resistance to corrosion, high strength, and excellent mechanical properties across a wide range of temperatures. It is widely used in industries where durability and reliability are critical, such as marine engineering, chemical processing, and oil and gas. The alloy is available in plate and sheet forms, making it versatile for various fabrication and construction applications.

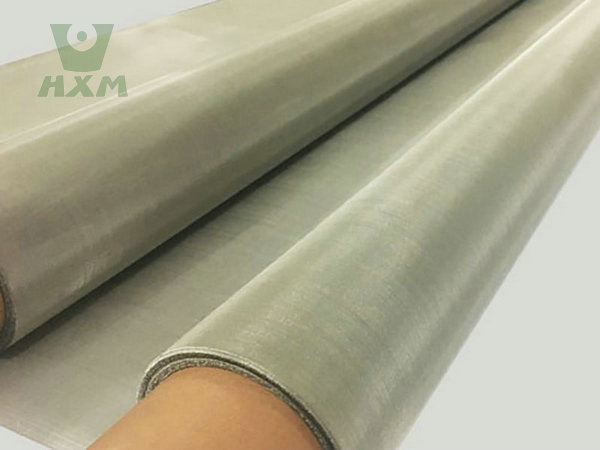

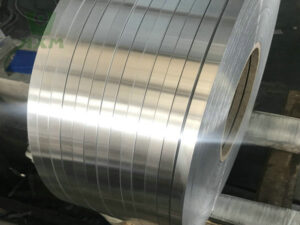

Huaxiao Metal Supplier provides all sizes of Monel alloy bar for sale. Customized specifications are available upon request. Additionally, the exact chemical composition and mechanical properties may vary slightly within the ranges listed, depending on the specific alloy formulation and production process. Custom sizes are also available upon request. Welcome to inquire, and learn about more details about the alloy wire. Of course, our company has the other shapes monel alloy, such as bar, strip, plate, sheet and so on.

Monel 400 wire conforms to standards such as ASTM B127, ASME SB127, and AMS 4544. It is available in a range of specifications, including wire diameter, mesh size, and overall dimensions tailored to meet customer requirements. Huaxaio Metal Manufacturer has various alloy products for sale and the service is customerized for you.

| Specification | Range |

|---|---|

| Wire Diameter | 0.1mm to 5mm |

| Mesh Size | Various sizes available upon request |

| Material Form | Wire mesh |

Monel 400 Wire Mesh Data Sheets

Monel 400 wire mesh alloy is a nickel-copper alloy renowned for its exceptional corrosion resistance and high-temperature performance. It is widely utilized across various industries due to its robust mechanical properties and ability to withstand harsh environments. This alloy is particularly suitable for applications where resistance to chloride stress corrosion cracking is crucial, making it an ideal choice for marine and chemical processing industries.

Chemical Composition of Monel 400 Wire

The chemical composition of Monel 400 wire mesh alloy is carefully balanced to provide optimal corrosion resistance and mechanical properties. The typical composition range is as follows:

| Element | Composition Range (Weight %) |

|---|---|

| Nickel (Ni) | 63.0 – 70.0 |

| Copper (Cu) | 28.0 – 34.0 |

| Iron (Fe) | ≤ 2.50 |

| Sulfur (S) | ≤ 0.024 |

| Carbon (C) | ≤ 0.3 |

| Silicon (Si) | ≤ 0.5 |

| Manganese (Mn) | ≤ 2.0 |

Monel 400 wire mesh is manufactured from Monel 400 alloy, which complies with international standards such as:

ASTM B164: Standard specification for nickel-copper alloy rods, bars, and wires.

AMS 4676: Aerospace material specification for bars, forgings, and rings.

The wire mesh is available in various weave types (e.g., plain weave, twill weave) and mesh sizes to meet specific application requirements.

Physical Properties of Monel 400 Mesh

Monel 400 wire mesh alloy exhibits excellent physical properties, making it suitable for a wide range of applications. Huaxiao Metal Supplier has the good quality alloy products. Key physical properties include:

| Property | Value |

|---|---|

| Density | 8.83 g/cm³ |

| Melting Point | 1300 – 1393 °C |

| Thermal Conductivity | 21.8 W/mK |

| Coefficient of Thermal Expansion | 13.8 μm/m-K (0-100 °C) |

Please note that the above specifications are typical and may vary slightly based on the manufacturer, production batch, and specific application requirements. For precise specifications and availability, it is recommended to consult with a supplier or manufacturer of Monel alloy plates. Huaxiao Metal Manufacturer also provides other shapes of Monel products, such as bar, strip, coil, plate&sheet, tube&pipe. The price is affordable and suitable.

Mechanical Properties of Monel 400 Wire

Huaxiao Metal Supplier has the good quality alloy products and the service is good. The mechanical properties of Monel 400 wire mesh vary depending on its condition (annealed or cold-worked). Below is a comparison:

| Property | Annealed Condition | Cold-Worked Condition |

|---|---|---|

| Tensile Strength | 550 MPa (80 ksi) | 760 MPa (110 ksi) |

| Yield Strength | 240 MPa (35 ksi) | 550 MPa (80 ksi) |

| Elongation | 40% | 20% |

| Hardness (Rockwell B) | 65 – 85 | 90 – 100 |

The alloy’s high tensile and yield strengths, combined with good elongation, make it ideal for structural and filtration applications. Huaxaio Metal Manufacturer has the professional experts to offer the solutions for your questions.

What are the Monel 400 Mesh Benefits?

Monel alloy Meshes in construction offer significant benefits, including excellent corrosion and high-temperature resistance, high strength and ductility, good weldability, and versatility for use in a wide range of demanding environments. Monel Alloy Wire Mesh exhibits excellent corrosion resistance to a variety of media, including seawater, sulfuric acid, ammonia, and other non-oxidizing agents. It maintains its corrosion resistance in both dry and wet harsh environments, making it particularly suitable for marine and chemical applications. Welcome to Huaxiao Metal Supplier to request the price, trust you can be satisfied in the alloy products, looking forward to your consultation.

Tips for Procurement and Cost-Effectiveness

Supplier Selection: Choose suppliers with certifications (e.g., ISO, ASTM) to ensure quality.

Bulk Purchasing: Buying in bulk can reduce costs.

Customization: Opt for tailored dimensions to minimize waste.

Market Trends: Monitor nickel and copper prices, as they influence Monel 400 pricing.

Alloy Procurement

When procuring Monel 400 wire mesh, consider the following:

Standards Compliance: Ensure the material meets ASTM B164 or other relevant standards.

Testing Certificates: Request mill test reports (MTRs) for quality assurance.

Lead Time: Plan for potential delays due to high demand.

Monel 400 Wire Advantages

Monel 400 Wire alloy is a nickel-copper alloy renowned for its exceptional corrosion resistance in a wide range of environments, including sea water, salt spray, and various chemical solutions. It combines high strength with good ductility, making it an ideal choice for applications requiring both mechanical integrity and corrosion resistance. Monel 400 Mesh is available in various thicknesses, widths, and lengths, tailored to meet specific industrial needs.Huaxiao Metal Supplier has the good quality monel alloy products in China, and the delievery is fast , the service is good for every customers, and welcome to inquire the lastest price that I believe you will be satisfied with the price and work with us.

Corrosion Resistance: Excellent resistance to seawater, acids, and alkalis.

High Strength: Maintains strength at both high and low temperatures.

Durability: Long service life in harsh environments.

Versatility: Suitable for a wide range of industrial applications.

Ease of Fabrication: Can be welded, machined, and formed easily.

Monel 400 Wire Applications and Uses

Monel 400 wire mesh is a high-performance material offering unmatched corrosion resistance, strength, and durability. Its versatility and cost-effectiveness make it a preferred choice for demanding applications across industries. By understanding its properties, procurement strategies, and market dynamics, businesses can maximize the value of this exceptional alloy. Our company has the good service and quality assurance in Alloy products, if you have any questions, you can require our staff or experts freely, they will provide the customerized solution for you.

Huaxiao Metal Supplier provides all kinds of monel alloy plate and sheet in the world. Welcome to inquiry.

- Marine and Offshore: Used in shipbuilding, valves, pumps, and shafts in seawater and brine environments.

- Chemical Processing: Suitable for equipment handling fluoride, hydrochloric acid, sulfuric acid, and alkaline solutions.

- Oil and Gas: Applied in splash zones of offshore structures and acidic gas applications.

- Power Generation: Utilized in water heaters and steam generators in power plants.

- Water Treatment: Ideal for brine heaters and evaporators in seawater desalination plants.

Data Analysis and Comparison

To further illustrate the advantages of Monel 400 wire mesh, consider the following comparison table:

| Property | Monel 400 | Stainless Steel 316 | Inconel 625 |

|---|---|---|---|

| Corrosion Resistance | Excellent | Good | Excellent |

| Tensile Strength (MPa) | 550 – 760 | 515 | 930 |

| Cost (USD/lb) | 15−15−25 | 3−3−5 | 20−20−30 |

| Temperature Range | -240°C to 540°C | -200°C to 870°C | -200°C to 980°C |

This analysis highlights Monel 400’s balanced performance in terms of strength, corrosion resistance, and cost, making it a reliable choice for critical applications.

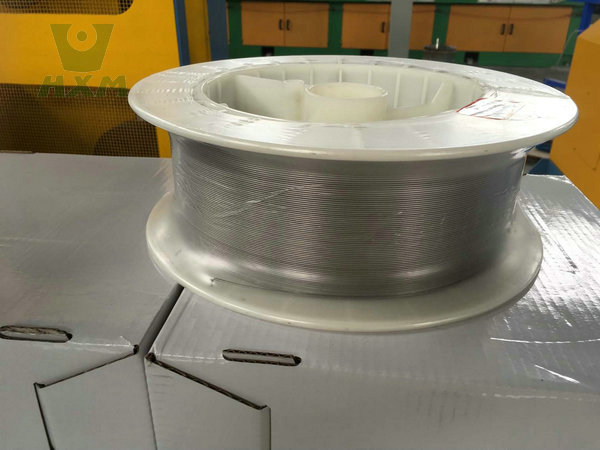

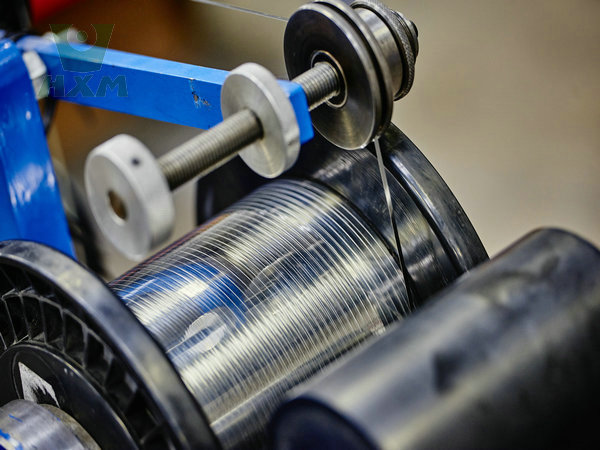

Monel Wire Alloy Factory

Huaxiao Metal Supplier provides professional services and reasonable prices, offering customers the best quality products. The Monel Alloy Factory is a specialized manufacturing facility dedicated to the production of high-quality Monel alloy. This factory combines advanced technology, rigorous quality control, and experienced personnel to ensure the production of Monel alloy that meet the highest standards.The factory is equipped with state-of-the-art production equipment and machinery, capable of producing Monel alloy with precise dimensions and consistent quality.Welcome to reqiure, and ask to the price.

Mill Test Certificate is supplied with shipment, Third Part Inspection is acceptable. Our knowledgeable staff and resident metallurgists will be pleased to assist you further on any technical topic.

Our factory specializes in the production of high-quality Monel 400 wires, a nickel-copper alloy renowned for its corrosion resistance and mechanical properties. Our Monel 400 wires are precision-engineered to meet the rigorous standards of various industries, including marine, chemical, and oil & gas.

The chemical composition of Monel 400 meshes comprises approximately 63-67% nickel, 23-30% copper, and trace elements of iron, manganese, carbon, and silicon. This solid solution alloy can only be hardened by cold working, ensuring its durability and reliability.

Our factory is equipped with advanced production lines and testing equipment, enabling us to produce Monel 400 wires with consistent quality and precise dimensions. We offer custom solutions to cater to specific customer requirements, ensuring timely delivery and exceptional customer service.

Why Choose Us?

Monel 400 wire is a high-performance material offering unmatched corrosion resistance, strength, and durability. Its versatility and cost-effectiveness make it a preferred choice for demanding applications across industries. By understanding its properties, procurement strategies, and market dynamics, businesses can maximize the value of this exceptional alloy. Huaxiao Metal Supplier has the special solution about alloy problems.

As a leading professional metal supplier, we distinguish ourselves through the following advantages:

Uncompromising Quality Assurance

Our Monel 400 wire undergoes rigorous testing to meet ISO standards, ensuring optimal corrosion resistance (e.g., in hydrofluoric acid, seawater) and mechanical strength (tensile strength ≥480 MPa). Each batch is certified with full traceability, guaranteeing reliability in critical applications like marine engineering or chemical processing.Customization & Precision

We offer tailored solutions, including diameters from 0.025mm to 21mm, and packaging options (coils, spools, or cut lengths). Our advanced CNC machining capabilities enable precise fabrication for specialized needs, such as aerospace components or valves.Technical Expertise & Support

Our team of metallurgists provides 24/7 guidance on material selection, welding procedures (e.g., TIG welding best practices), and post-processing solutions. We also offer documentation compliance for industries like nuclear power or oil/gas.

FAQ

Can you provide samples?

For small parts, we can provide free samples of regular sizes, but the shipping costs must be borne by you. For large samples, we will include it in the order amount. Please confirm with our sales department according to your specific requirements.

What is the function of Monel 400?

Monel 400 balances cost-efficiency with long-term reliability, making it a staple in aerospace, marine, and petrochemical sectors.

Do you support customized sizes?

We provide various forms such as plates, rods, and pipes, with a minimum processing accuracy of ± 0.02mm. The customization cycle is usually 7-15 working days, and specific details need to be confirmed with the sales team.

How long is your delivery time?

It is usually 35 days, but it is also affected by your specific requirements or order quantity.

What is the minimum order quantity?

Our minimum order quantity is 100kg. Larger quantity, lower price.

How do you control product quality?

From raw material selection to packaging for transport, each production step undergoes rigorous testing and evaluation. Only products that pass all tests are approved for export.

Arabic

Arabic Dutch

Dutch English

English French

French German

German Italian

Italian Japanese

Japanese Korean

Korean Portuguese

Portuguese Romanian

Romanian Russian

Russian Spanish

Spanish