| Specification | Details |

|---|---|

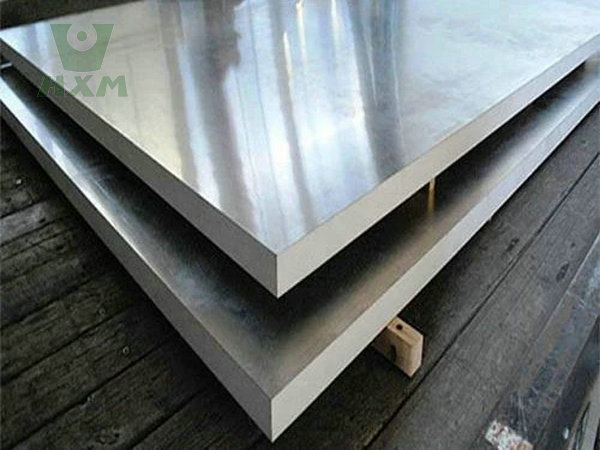

| Thickness Range | 0.5mm – 100mm (0.02″ – 3.94″) |

| Standard Widths | 1000mm, 1219mm, 1500mm (39.4″, 48″, 59″) |

| Standard Lengths | 2000mm, 2438mm, 3000mm (78.7″, 96″, 118″) |

| Coil Availability | Widths up to 1500mm (59″), ID 508mm/610mm (20″/24″) |

| Tolerances | Thickness: ±0.05mm (±0.002″) |

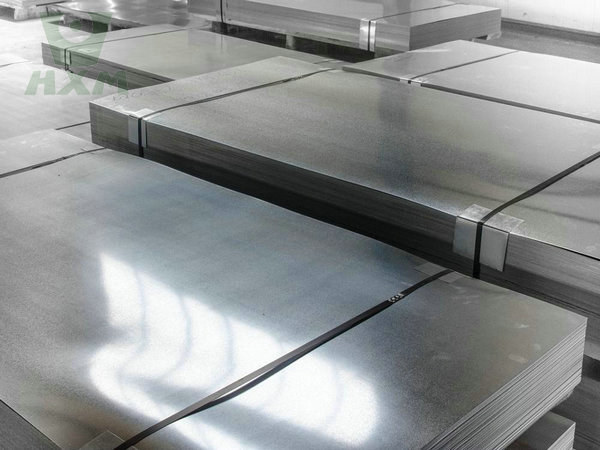

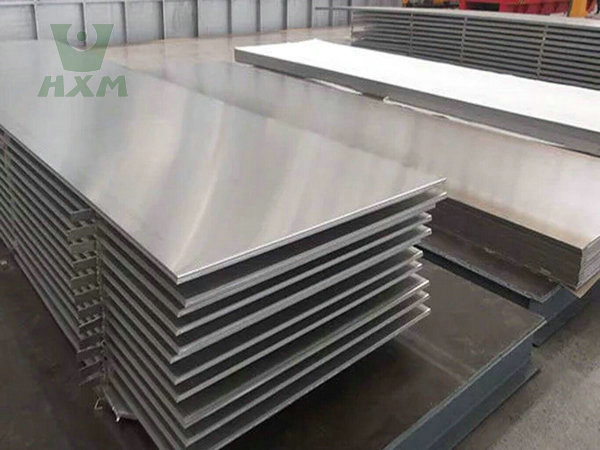

Titanium TC11 ( Ti-6.5Al-3.5Mo-1.5Zr-0.3Si) is a near-alpha titanium alloy renowned for its exceptional strength-to-weight ratio, corrosion resistance, and high-temperature stability (up to 400°C). It is widely used in aerospace, medical implants, and chemical processing equipment. Huaxiao Metal Manufacturer has the good quality titanium TC11 plate.

Technical Specifications Table

| Property | Specification | Competitor Average | TC11 Advantage |

|---|---|---|---|

| Tensile Strength (MPa) | 895–950 | 850–900 | +6% Higher Strength |

| Yield Strength (MPa) | 825–880 | 780–830 | +5% Higher Durability |

| Elongation (%) | 12–15 | 10–12 | Better Formability |

| Hardness (HB) | 310–340 | 290–320 | Improved Wear Resistance |

| Density (g/cm³) | 4.5 | 4.5 | Same as Competitors |

| Max Service Temp (°C) | 400 | 350 | +50°C Heat Tolerance |

The titanium alloy sheet is processing in our factory and if you want to visit, you can contact us, we will provide the professional service for your reception. I am conveniced that you will like to our products quickly.

Overview of Titanium TC11 Plate

Titanium TC11 Plate/Sheet is a high-strength, corrosion-resistant alloy primarily used in aerospace, medical, and chemical industries. Its exceptional strength-to-weight ratio and heat resistance (up to 400°C) make it ideal for aircraft components, engine parts, and marine equipment. In medicine, it serves as a biocompatible material for implants and surgical tools. Its durability in harsh environments also suits chemical processing and offshore applications. Customizable in size, thickness, and finish, it meets precise engineering demands while ensuring longevity and performance.

Chemical Composition (ASTM B265 Compliant)

| Element | TC11 (%) | Industry Standard |

|---|---|---|

| Aluminum (Al) | 5.0–6.0 | 5.0–6.0 |

| Tin (Sn) | 1.5–2.5 | 1.5–2.5 |

| Iron (Fe) | ≤0.30 | ≤0.30 |

| Oxygen (O) | ≤0.18 | ≤0.20 |

| Carbon (C) | ≤0.10 | ≤0.10 |

Key Applications

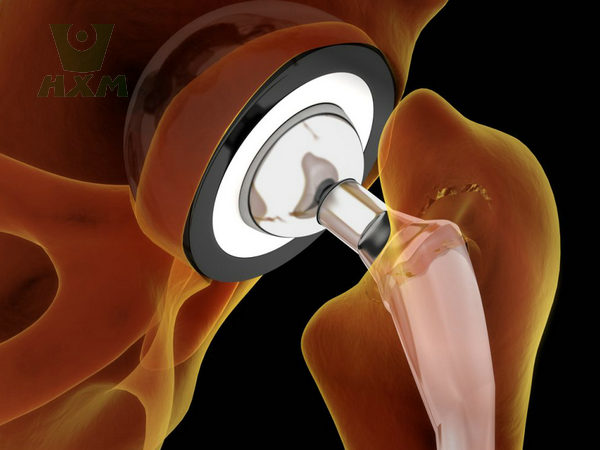

- Aerospace: Engine components, compressor blades, and structural frames.

- Medical: Orthopedic implants, dental instruments, and surgical tools.

- Chemical Processing: Heat exchangers, pressure vessels, and piping systems.

- Marine: Propeller shafts, hull components, and offshore drilling equipment.

Advantages of Titanium TC11 Plate

TC11 titanium sheet/plate is a heat-resistant near-α titanium alloy engineered for sustained performance at 500-550°C (932-1022°F). With its optimized composition (Ti-6.5Al-3.5Mo-1.5Zr-0.3Si), it delivers superior creep resistance, exceptional fatigue strength, and outstanding weldability versus standard TC4 (Ti-6Al-4V). Available in thicknesses 0.5–100mm with custom heat treatments, our TC11 complies with GB/T 2965, AMS 4986, and ISO 5832-11 for aerospace, power generation, and high-stress industrial applications. As the leading titanium supplier in China, our company has the assurance for the products, the delivery is fast and the service is satisfied for every customers.

High-Temperature Dominance

Retains 85% of room-temperature strength at 500°C vs. TC4’s 60% degradation

50% higher creep rupture life than TC4 at 450°C/300MPa

Fatigue & Fracture Resilience

Fatigue strength: 550 MPa (R=0.1, 10⁷ cycles) at 400°C

Exceptional crack propagation resistance under thermal cycling

Corrosion & Oxidation Resistance

Forms protective Al₂O₃/SiO₂ scale at 500°C (oxidation rate: <0.5 mg/cm²/100h)

Immune to chloride/SCC in marine/chemical environments

Manufacturing Efficiency

Superplastic Forming (SPF) capability: 800–900°C elongation >400%

Weldability: Compatible with TIG, EBW, and laser welding

Application of Titanium TC11 Sheet

The Titanium TC11 Sheet is commonly used in many industrial industries. Its performance and functionality are both excellent, and it has different roles in different industries. If you would like to learn more about this product, please click the button below, fill out the form and write down your question. Our experts will reply to you within 24 hours and provide you with personalized solutions. Welcome to inquire and ask for the lastest price for sale in China.

| Sector | Critical Components | Performance Driver |

|---|---|---|

| Aerospace | Jet engine compressor discs/blades, hypersonic skin panels | 550°C stability + 40% weight savings vs. nickel alloys |

| Power Generation | Gas turbine blades, nuclear reactor cladding | Radiation resistance + creep performance |

| Automotive Racing | Turbocharger rotors, exhaust valves | Thermal fatigue resistance |

| Chemical Processing | High-temperature reactor vessels | Acid/chloride immunity |

| Medical | Sterilizable surgical tools | Biocompatibility (ISO 10993 certified) |

Why Source TC11 from Us?

- Premium Quality – Manufactured to ASTM B265, AMS 4911, MIL-T-9046 standards.

- Custom Sizing & Finishes – Available in various thicknesses (0.5mm to 50mm) with polished, brushed, or blasted surfaces.

- Fast Lead Times & Global Shipping – Reliable supply chain for bulk orders.

- Competitive Pricing – Cost-effective solutions for high-performance applications.

Titanium TC11 sheet and plate offer a premium solution for applications where heat resistance, structural performance, and long-term reliability are paramount. Whether you’re sourcing for aerospace parts, industrial turbines, or high-temperature processing systems, TC11 delivers unmatched value through durability and thermal stability.

Contact us now for technical consultation, free samples, and tailored quotation. Partner with a trusted Chinese supplier of high-grade titanium materials for your next mission-critical project.