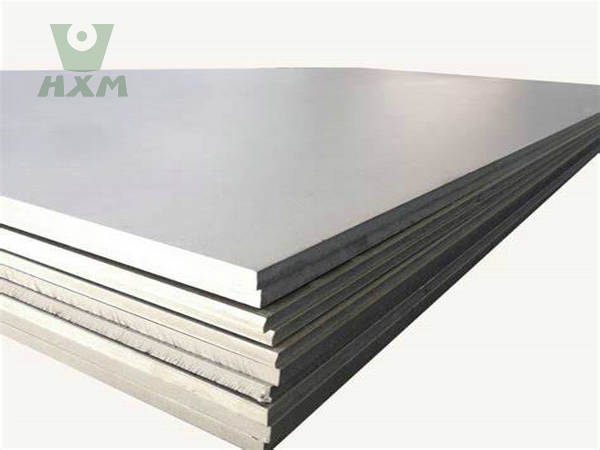

Titanium TA9 Plate&Sheet, please note that the above table provides a range of standard thicknesses, widths, and lengths for Titanium TA7 Alloy.

- Dimensions:

- Thickness: 2.5mm – 50mm

- Width: 50mm – 2000mm

- Length: 100mm – 6000mm

- Certification: ISO, SGS, BV and so on.

- *Customized size needs to be confirmed with us

- Grades:TA1, TA2, TA3, TA7, TA9, TA10, TA18, TC4, TC11, Gr9, Ti-6Al-4V.

Titanium TA9 Plate Size And Specifications

Huaxiao Metal Supplier provides all sizes of Titanium alloy plate for sale. Customized specifications are available upon request. Additionally, the exact chemical composition and mechanical properties may vary slightly within the ranges listed, depending on the specific alloy formulation and production process. Custom sizes are also available upon request. Welcome to inquire, and learn about more details about the TA9 alloy plate.

Available Product Forms

Hot-rolled plates (3mm to 100mm thickness)

Cold-rolled sheets (0.5mm to 10mm thickness)

Annealed or cold-worked tempers

Standard widths up to 1500mm (can be customized)

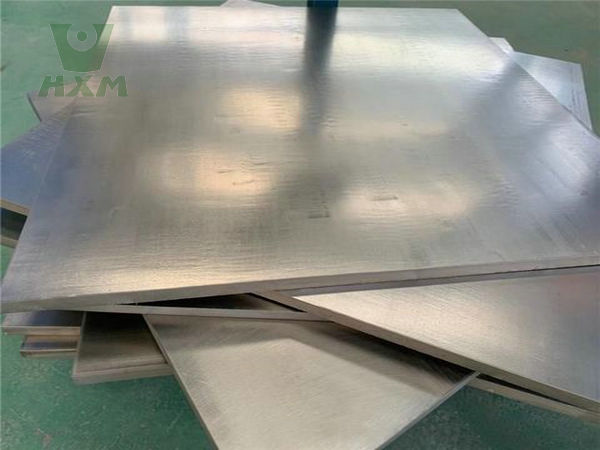

Vacuum arc remelting (VAR) for ingot production

Forging/billet conversion at β-transus+50°C

Hot rolling in α-β phase field

Cold rolling (for sheet products)

Final annealing at 700-800°C

Titanium TA9 (ASTM B265 Grade 9, UNS R56320), commonly known as Ti-3Al-2.5V, is a near-alpha titanium alloy offering an exceptional balance of strength, weldability and corrosion resistance. This medium-strength alloy bridges the gap between commercially pure titanium and high-strength alloys like Ti-6Al-4V, making it particularly valuable for applications requiring both formability and enhanced mechanical properties.

Chemical Composition of Titanium TA9 Sheet

| Element | Composition (wt%) | Function |

|---|---|---|

| Titanium | Balance | Matrix |

| Aluminum | 2.5-3.5 | α stabilizer, strength |

| Vanadium | 2.0-3.0 | β stabilizer, ductility |

| Iron | ≤0.25 | Impurity control |

| Oxygen | ≤0.15 | Interstitial strengthener |

| Carbon | ≤0.08 | Interstitial control |

| Nitrogen | ≤0.03 | Interstitial control |

| Hydrogen | ≤0.0125 | Embrittlement control |

Please note that the above specifications are typical and may vary slightly based on the manufacturer, production batch, and specific application requirements. For precise specifications and availability, it is recommended to consult with a supplier or manufacturer of Titanium alloy plates. Huaxiao Metal Manufacturer also provides other shapes of Precision products, such as bar, coil, strip, tube&pipe, wire&mesh .The price is affordable and suitable.

Physical Properties of Titanium TA9 Plate

| Property | Value | Notes |

|---|---|---|

| Density | 4.48 g/cm³ | 40% lighter than steel |

| Melting Range | 1604-1660°C | – |

| Thermal Conductivity | 7.2 W/m·K @ 25°C | Lower than CP Ti |

| Electrical Resistivity | 1.6 μΩ·m | 28% higher than CP Ti |

| Coefficient of Thermal Expansion | 9.1×10⁻⁶/°C (20-100°C) | Similar to austenitic steels |

| Magnetic Permeability | 1.00005 | Essentially non-magnetic |

Mechanical Properties

| Property | Annealed Condition | Cold Worked Condition |

|---|---|---|

| Tensile Strength | 620-760 MPa | 690-860 MPa |

| Yield Strength (0.2% offset) | 480-620 MPa | 580-760 MPa |

| Elongation (50mm) | 15-20% | 10-15% |

| Reduction of Area | 35-45% | 25-35% |

| Hardness (HRB) | 80-95 | 85-100 |

| Modulus of Elasticity | 103-110 GPa | 105-112 GPa |

| Shear Modulus | 39-42 GPa | 40-43 GPa |

What are the Titanium TA9 Sheet Benefits?

Titanium TA9 Sheets have a wide range of applications due to their unique combination of properties. Titanium alloy plates are used in some electronic components and communication equipment due to their electrical conductivity and corrosion resistance.Titanium TA9 plates are versatile materials with a wide range of applications across different industries. Their unique combination of properties makes them ideal for use in demanding environments and critical applications.Welcome to Huaxiao Metal Manufacturer to request the price, trust you can be satisfied in the alloy products and buy our products in quickly. Our services are in providing comprehensive and support to clients.

Titanium TA9 Plate Applications and Uses

Huaxiao Metal Supplier provides all kinds of titanium alloy plate in the world. Welcome to inquiry and ask for the price.

| Industry | Typical Applications | Why TA9 is Used |

|---|---|---|

| Aerospace | Hydraulic tubing, ducting | Strength+weight savings |

| Marine | Heat exchangers, hull components | Corrosion resistance |

| Chemical | Reaction vessels, piping | Acid resistance |

| Medical | Surgical instruments | Biocompatibility+strength |

| Automotive | Exhaust systems, springs | High temp performance |

Titanium TA9 Plate Advantages

| Characteristic | TA9 vs CP Ti | TA9 vs Ti-6Al-4V | TA9 vs 316L SS |

|---|---|---|---|

| Strength | +40% higher | -20% lower | Comparable |

| Formability | -10% lower | +50% better | +30% better |

| Corrosion Resistance | Equal | Equal | Superior in reducing acids |

| Weldability | Excellent | Good | Excellent |

| Fatigue Strength | +25% higher | -15% lower | +40% higher |

| Cost | +30% higher | -20% lower | +300% higher |

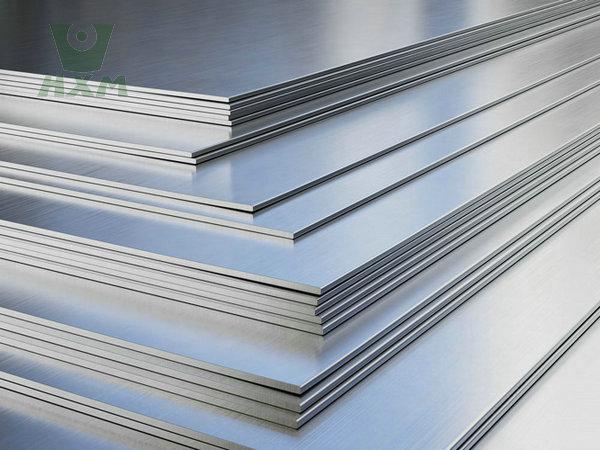

Alloy Factory

Huaxiao Metal Supplier provides professional services and reasonable prices, offering customers the best quality products. The Titanium Alloy Factory is a specialized manufacturing facility dedicated to the production of high-quality titanium alloy plates. This factory combines advanced technology, rigorous quality control, and experienced personnel to ensure the production of titanium alloy sheets that meet the highest standards.The factory is equipped with state-of-the-art production equipment and machinery, capable of producing titanium alloy sheets with precise dimensions and consistent quality. Welcome to require, and ask to the price.

In Conclusion

Titanium TA9 plate and sheet represent a premium material solution for industries demanding uncompromising performance in extreme environments.Titanium TA9 (Ti-3Al-2.5V) plate and sheet products offer an optimal balance between the excellent corrosion resistance of commercially pure titanium and the enhanced mechanical properties of high-strength alloys like Ti-6Al-4V.

For manufacturers seeking to optimize weight, durability, and cost-efficiency, TA9 titanium alloy offers a compelling value proposition that aligns with the demands of modern high-performance engineering.