Titanium TA10 Plate&Sheet, please note that the above table provides a range of standard thicknesses, widths, and lengths for Titanium TA10 Alloy.

- Dimensions:

- Thickness: 2.5mm – 50mm

- Width: 50mm – 2000mm

- Length: 100mm – 6000mm

- Certification: ISO, SGS, BV and so on.

- *Customized size needs to be confirmed with us

- Grades:TA1, TA2, TA3, TA7, TA9, TA10, TA18, TC4, TC11, Gr9, Ti-6Al-4V.

Titanium TA10 Plate Size And Specifications

Huaxiao Metal Supplier provides all sizes of Titanium alloy plate for sale. Customized specifications are available upon request. Additionally, the exact chemical composition and mechanical properties may vary slightly within the ranges listed, depending on the specific alloy formulation and production process. Custom sizes are also available upon request. Welcome to inquire, and learn about more details about the TA10 alloy plate.(Ti-3Al-2.5V)

Available Product Forms

Hot-rolled plates (3mm to 100mm thickness)

Cold-rolled sheets (0.5mm to 10mm thickness)

Annealed or cold-worked tempers

Standard widths up to 1500mm (can be customized)

Vacuum arc remelting (VAR) for ingot production

Forging/billet conversion at β-transus+50°C

Hot rolling in α-β phase field

Cold rolling (for sheet products)

Final annealing at 700-800°C

Titanium TA10 (ASTM B265 Grade 10, UNS R56320) is a near-alpha titanium alloy optimized for superior corrosion resistance, weldability, and medium strength. Designed as an upgrade to CP titanium grades, it bridges the gap between commercially pure titanium (Grade 2) and high-strength alloys like Ti-6Al-4V (Grade 5).

Key Highlights:

Enhanced Strength: 2x stronger than CP titanium (Grade 2).

Exceptional Corrosion Resistance: Ideal for marine and chemical environments.

Superior Formability: Easier to machine and weld than Ti-6Al-4V.

Chemical Composition of Titanium TA10 Sheet (ASTM B265 Standard)

| Element | Composition (wt%) | Function |

|---|---|---|

| Titanium (Ti) | Balance | Matrix |

| Aluminum (Al) | 2.5-3.5 | α stabilizer, strength |

| Vanadium (V) | 2.0-3.0 | β stabilizer, ductility |

| Iron (Fe) | ≤0.25 | Impurity control |

| Oxygen (O) | ≤0.15 | Interstitial strengthener |

| Carbon (C) | ≤0.08 | Grain refinement |

| Nitrogen (N) | ≤0.03 | Interstitial control |

| Hydrogen (H) | ≤0.0125 | Embrittlement control |

Note: Low oxygen content (<0.15%) ensures excellent weldability.

Please note that the above specifications are typical and may vary slightly based on the manufacturer, production batch, and specific application requirements. For precise specifications and availability, it is recommended to consult with a supplier or manufacturer of Titanium alloy plates. Huaxiao Metal Manufacturer also provides other shapes of Precision products, such as bar, coil, strip, tube&pipe, wire&mesh .The price is affordable and suitable.

Physical Properties of Titanium TA10 Plate

| Property | TA10 (Ti-3Al-2.5V) | CP Ti Grade 2 | Ti-6Al-4V (Grade 5) |

|---|---|---|---|

| Density (g/cm³) | 4.51 | 4.50 | 4.43 |

| Melting Range (°C) | 1604-1660 | 1668 | 1604-1660 |

| Thermal Conductivity (W/m·K) | 7.2 | 16.4 | 6.7 |

| Electrical Resistivity (μΩ·m) | 1.6 | 0.55 | 1.7 |

| CTE (10⁻⁶/°C, 20-100°C) | 9.4 | 8.6 | 9.1 |

Our company’s products have quality certificates and third-party testing certificates, and the prices are reasonable. If you want to learn more about metals, please feel free to contact us by clicking the button below. I believe you will be satisfied with the price of my product. If you need customized products, you can send us an email with specific specifications and sizes. Our experts will provide you with free solutions, and we hope to establish a long-term friendly trade partner through cooperation.

Mechanical Properties

| Property | TA10 | Grade 2 | Grade 5 |

|---|---|---|---|

| Tensile Strength (MPa) | 550-760 | 345-483 | 895-930 |

| Yield Strength (MPa) | 485-620 | 275-345 | 825-869 |

| Elongation (%) | 15-20 | 20-25 | 10-15 |

| Hardness (HV) | 180-220 | 140-180 | 280-350 |

| Fatigue Limit (MPa, 10⁷ cycles) | 300 | 240 | 450 |

Key Takeaway:

Higher strength than Grade 2, but more ductile than Grade 5.

Better fatigue resistance than CP titanium.

What are the Titanium TA10 Sheet Benefits?

Titanium TA10 Sheets have a wide range of applications due to their unique combination of properties. Titanium alloy plates are used in some electronic components and communication equipment due to their electrical conductivity and corrosion resistance.Titanium TA10 plates are versatile materials with a wide range of applications across different industries. Their unique combination of properties makes them ideal for use in demanding environments and critical applications.Welcome to Huaxiao Metal Manufacturer to request the price, trust you can be satisfied in the alloy products and buy our products in quickly. Our services are in providing comprehensive and support to clients.

Titanium TA10 Plate Applications and Uses

Huaxiao Metal Supplier provides all kinds of titanium alloy plate in the world. Welcome to inquiry and ask for the price.

| Industry | Applications | Why TA10? |

|---|---|---|

| Marine | Ship hulls, heat exchangers | Superior seawater resistance |

| Chemical | Reactors, piping | HCl/H₂SO₄ resistance |

| Aerospace | Hydraulic tubing | Lightweight + strength |

| Medical | Surgical tools, implants | Biocompatibility |

| Automotive | Exhaust systems | High-temp stability |

Titanium TA10 Plate Advantages

1. Superior Corrosion Resistance in Reducing Environments

- Mechanism: Titanium TA10 (Ti-0.3Mo-0.8Ni) achieves corrosion resistance through molybdenum (Mo) and nickel (Ni) additions, which form a stable passive oxide layer.

- Performance:

- Excellent in sulfuric acid (H₂SO₄), hydrochloric acid (HCl), and phosphoric acid (H₃PO₄) at low-to-moderate concentrations.

- Resists seawater corrosion, making it ideal for marine and offshore applications.

- Outperforms standard Grade 2 titanium in reducing acid environments by 3–5x in service life.

2. Cost-Effective Alternative to Palladium-Containing Alloys

- Comparison with TA9 (Ti-0.2Pd):

- TA10 costs 40–60% less than TA9 due to the absence of palladium (Pd), a rare and expensive metal.

- Maintains 90% of TA9’s corrosion performance in non-stagnant, reducing acidic conditions.

- Cost-Saving Example:

- A 10-ton order of TA10 plates costs 350,000–450,000, while TA9 would cost 800,000–1,200,000.

3. High Strength-to-Weight Ratio

- Mechanical Properties:

- Yield Strength: ≥275 MPa (annealed)

- Tensile Strength: ≥480 MPa (annealed)

- Density: 4.51 g/cm³ (40% lighter than steel)

- Benefit: Enables lightweight designs in aerospace, marine, and chemical processing without sacrificing durability.

4. Excellent Weldability and Fabrication Ease

- Why It Matters:

- TA10 is more forgiving during welding than TA9, reducing the risk of hydrogen embrittlement.

- Compatible with TIG, MIG, and electron beam welding methods.

- Cost Advantage: Lower fabrication costs due to fewer post-weld inspections and repairs.

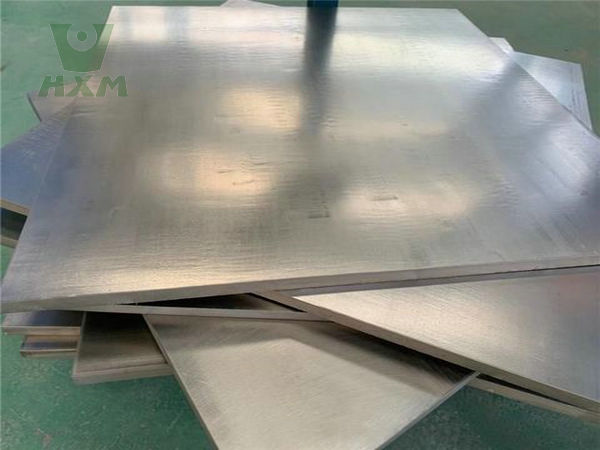

Alloy Factory

Huaxiao Metal Supplier provides professional services and reasonable prices, offering customers the best quality products. The Titanium Alloy Factory is a specialized manufacturing facility dedicated to the production of high-quality titanium alloy plates. This factory combines advanced technology, rigorous quality control, and experienced personnel to ensure the production of titanium alloy sheets that meet the highest standards.The factory is equipped with state-of-the-art production equipment and machinery, capable of producing titanium alloy sheets with precise dimensions and consistent quality. Welcome to require, and ask to the price.

When to Choose TA10:

- For chemical processing, desalination, marine, and oil & gas applications where crevice corrosion is not a dominant risk.

- When budget constraints require a balance between performance and affordability.

- For projects demanding high strength, low maintenance, and longevity in reducing environments.

Huaxiao Metal is a full line supplier of aerospace, marine, commercial grade alloys, and carbon steel. Our company provides fast and reliable products, offering convenient supply services to companies around the world. Inquire about our metal material supply plan, which enables our customers to advance their plans effectively and apply metal materials to various industries. Huaxiao Metal provides logical solutions to make your metal material management wise, safe, and cost-effective. Welcome to inquire and contact us today by clicking the below button.

In Conclusion

Titanium TA10 (Ti-0.3Mo-0.8Ni) stands out as a premium, cost-effective corrosion-resistant alloy for industrial applications where reducing acids, seawater, and moderate chloride exposure are primary concerns. Its unique combination of molybdenum and nickel additions provides robust passive oxide layer protection, ensuring long service life, high strength, and excellent weldability—all while reducing material and lifecycle costs by up to 60% compared to palladium-containing alternatives like TA9.

Key Strengths:

- Affordable Corrosion Resistance: Outperforms standard titanium grades in acidic and marine environments without the premium cost of palladium.

- Lightweight Durability: Offers a 40% weight reduction vs. steel while maintaining structural integrity under harsh conditions.

- Fabrication Efficiency: Easier to weld and form than TA9, minimizing post-processing risks and costs.

- Sustainability: 100% recyclable with a lower carbon footprint than Pd-based alloys.