Titanium Alloy Strip, please note that the above table provides a range of standard thicknesses, widths, and lengths for Titanium Alloy.

- Dimensions:

- Thickness: 0.05mm – 30mm

- Width: <600mm

- Certification: ISO, SGS, BV and so on.

- *Customized size needs to be confirmed with us

- Grades:TA1, TA2, TA3, TA7, TA9, TA10, TA18, TC4, TC11, GR1, GR2, GR3, GR4, GR5, GR7, GR9, GR12, Ti-6Al-4V.

Titanium Alloy Strip Size And Specifications

Huaxiao Metal Supplier provides all sizes of Titanium alloy strip for sale. Customized specifications are available upon request. Additionally, the exact chemical composition and mechanical properties may vary slightly within the ranges listed, depending on the specific alloy formulation and production process. Custom sizes are also available upon request. Welcome to inquire, and learn about more details about the alloy strip.

| Grade | Thickness (mm) | Width (mm) | Length (m) | Chemical Composition |

|---|---|---|---|---|

| GR1 | 0.1 – 3.0 | 10 – 1000 | Customizable | Ti: Bal., N: ≤0.03%, C: ≤0.08%, H: ≤0.015%, Fe: ≤0.2%, O: ≤0.18% |

| GR2 | 0.1 – 3.0 | 10 – 1000 | Customizable | Ti: Bal., N: ≤0.03%, C: ≤0.08%, H: ≤0.015%, Fe: ≤0.3%, O: ≤0.25% |

| GR5 | 0.1 – 3.0 | 10 – 1000 | Customizable | Ti: Bal., Al: ≤0.2%, V: 5.5 – 6.75%, Mo: 3.5 – 4.5%, Fe: ≤0.4%, O: ≤0.2%, N: ≤0.05%, C: ≤0.08%, H: ≤0.015% |

| GR9 | 0.1 – 3.0 | 10 – 1000 | Customizable | Ti: Bal., (with specific ranges for other elements tailored for high temperature applications) |

| TA1 | 0.1 – 3.0 | 10 – 1000 | Customizable | Ti: ≥99.5%, O: ≤0.18%, N: ≤0.03%, C: ≤0.08%, Fe: ≤0.2%, H: ≤0.015% |

| TA2 | 0.1 – 3.0 | 10 – 1000 | Customizable | Ti: Bal., (with impurity limits similar to TA1 but may include slight variations in alloying elements) |

Please note that the above specifications are typical and may vary slightly based on the manufacturer, production batch, and specific application requirements. For precise specifications and availability, it is recommended to consult with a supplier or manufacturer of Titanium alloy coils. Huaxiao Metal Manufacturer also provides other shapes of Precision products, such as bar, plate&sheet, coil, tube&pipe, wire&mesh .The price is affordable and suitable.

What are the Benefits?

Titanium alloy strips offer a multitude of benefits that make them highly suitable for various applications. Titanium alloy strips offer a combination of high strength, corrosion resistance, heat resistance, lightweight properties, good formability, biocompatibility, and durability. These benefits make them an excellent choice for a wide range of applications in aerospace, automotive, marine, chemical processing, medical, and other industries.Welcome to Huaxiao Metal Manufacturer to request the price, trust you can be satisfied in the alloy products and buy our products in quickly. Our services are in providing comprehensive and support to clients.

Titanium Alloy Strip Applications and Uses

Huaxiao Metal Supplier provides all kinds of titanium alloy strip in the world. Welcome to inquiry and ask for the price.

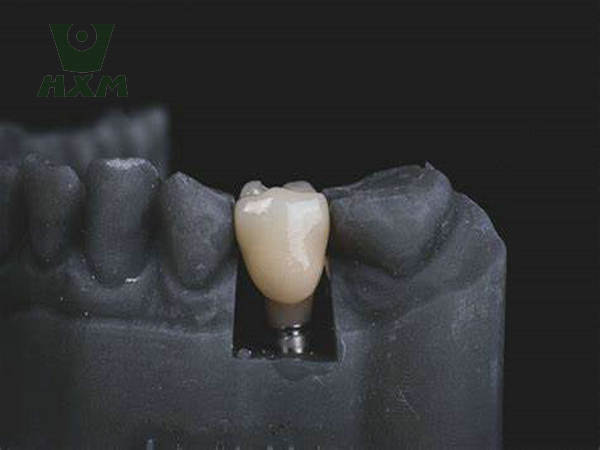

- Medical Industry:

- Implants: Due to their biocompatibility, titanium alloy strips are widely used in surgical implants such as hip replacements, dental implants, and orthopedic screws.

- Surgical Instruments: They are also used in the manufacture of surgical instruments due to their corrosion resistance and non-allergenic properties.

- Automotive Industry:

- Exhaust Systems: Titanium alloy strips are used in automotive exhaust systems for their lightweight properties and resistance to high temperatures.

- Suspension Components: They can also be found in suspension systems where strength and durability are required.

- Electronics and Communications:

- Connectors and Terminals: Titanium alloy strips are used in connectors and terminals due to their corrosion resistance and electrical conductivity.

- Antennas: They are also employed in the construction of antennas for their lightweight and durable properties.

Titanium Alloy Strip Advantages

High Strength-to-Weight Ratio:

- Titanium alloys have an excellent specific strength, which is the ratio of tensile strength to density. This means they can withstand significant loads while keeping the weight relatively low.

- This property is particularly advantageous in aerospace, automotive, and other industries where weight reduction is crucial for improving fuel efficiency and performance.

Excellent Corrosion Resistance:

- Titanium alloys form a protective oxide layer on their surface, which provides excellent resistance to corrosion from various environments, including saltwater, acids, and alkalis.

- This makes them ideal for use in marine environments, chemical processing, and other applications where corrosion is a concern.

Good Heat Resistance:

- Titanium alloys can maintain their mechanical properties at high temperatures, making them suitable for applications in engines, turbines, and other components that operate in hot environments.

- They can withstand temperatures up to several hundred degrees Celsius, depending on the specific alloy composition.

Lightweight:

- Titanium alloys are relatively lightweight compared to other metals like steel, which makes them desirable for applications where weight reduction is a priority.

- This contributes to fuel savings, reduced emissions, and improved overall system efficiency.

Good Formability and Fabrication Properties:

- Titanium alloy strips can be easily formed, welded, and machined into various shapes and sizes.

- This versatility allows for the creation of complex components and structures, tailored to specific application requirements.

Biocompatibility:

- Certain titanium alloys are biocompatible, meaning they do not cause adverse reactions when in contact with biological tissues.

- This makes them suitable for medical applications such as implants and surgical instruments.

Durability and Longevity:

- Due to their corrosion resistance, heat resistance, and high strength, titanium alloy strips offer a long service life in many applications.

- They can withstand harsh environments and maintain their performance over extended periods.

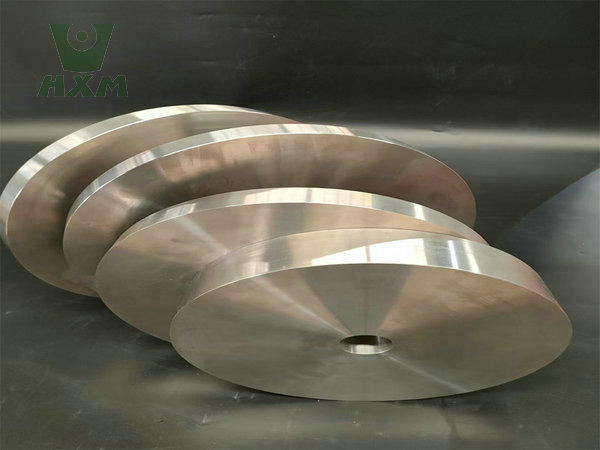

Alloy Factory

Huaxiao Metal Supplier provides professional services and reasonable prices, offering customers the best quality products. The Titanium Alloy Factory is a specialized manufacturing facility dedicated to the production of high-quality titanium alloy strips. This factory combines advanced technology, rigorous quality control, and experienced personnel to ensure the production of titanium alloy strips that meet the highest standards.The factory is equipped with state-of-the-art production equipment and machinery, capable of producing titanium alloy strips with precise dimensions and consistent quality. Welcome to require, and ask to the price.

You ask, we answer

We can provide small titanium alloy strip samples for you to check the quality. The sample is free, you only need to pay the shipping cost.

Precision alloy and titanium differ in composition, properties, and applications. Precision alloy is a specialized type of alloy material with various physical properties tailored for specific applications, while titanium is a lightweight, strong, corrosion-resistant metal widely used in aerospace, medical, and marine applications.

Titanium alloy is a versatile material with a wide range of applications due to its unique combination of properties.Titanium has a high affinity for oxygen atoms, forming a thin, dense oxide layer (TiO2) on its surface in room temperature atmospheric conditions, contributing to its exceptional corrosion resistance. It resists pitting, acid attack, stress corrosion, and has good resistance to alkalis, chlorides, chlorine-containing organic compounds, nitric acid, and sulfuric acid.