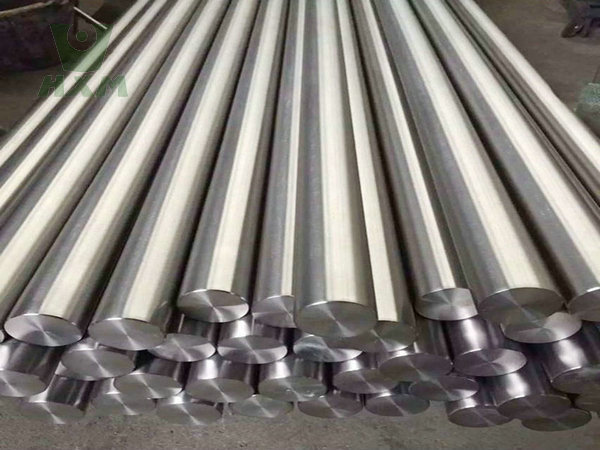

Titanium Alloy Bar, please note that the above table provides a range of standard thicknesses, widths, and lengths for Titanium Alloy.

- Dimensions:

- Outside Diameter: Φ4 – Φ300mm

- Delivery State: Cold Drawn, Hot Rolled, Forged, Grinding, Centerless Grinding

- Finish: Bright, Polishing, Mirror, Hairline, Pickled, Peeled, Black

- Shapes: Angle, Hexagon, Square, Channel, Round, Flat etc.

- Certification: ISO, SGS, BV and so on.

- *Customized size needs to be confirmed with us

- Grades:TA1, TA2, TA3, TA7, TA9, TA10, TA18, TC4, TC11, GR1, GR2, GR3, GR4, GR5, GR7, GR9, GR12, Ti-6Al-4V.

Titanium Alloy Bar Size And Specifications

Huaxiao Metal Supplier provides all sizes of Titanium alloy bar for sale. Customized specifications are available upon request. Additionally, the exact chemical composition and mechanical properties may vary slightly within the ranges listed, depending on the specific alloy formulation and production process. Custom sizes are also available upon request. Welcome to inquire, and learn about more details about the alloy bar.

| Grade | Size (Diameter x Length) | Chemical Composition | Tensile Strength (MPa) | Elongation (%) | Reduction of Area (%) |

|---|---|---|---|---|---|

| GR1 | (3.0200) mm x (5004000) mm | Ti: Bal., N: ≤0.03%, C: ≤0.08%, H: ≤0.015%, Fe: ≤0.2%, O: ≤0.18% | ≥240 | ≥24 | ≥30 |

| GR2 | (3.0200) mm x (5004000) mm | Ti: Bal., N: ≤0.03%, C: ≤0.08%, H: ≤0.015%, Fe: ≤0.3%, O: ≤0.25% | ≥400 | ≥20 | ≥30 |

| GR3 | (3.0200) mm x (5004000) mm | Ti: Bal., N: ≤0.05%, C: ≤0.08%, H: ≤0.015%, Fe: ≤0.3%, O: ≤0.35% | ≥500 | ≥18 | ≥30 |

| GR4 | (3.0200) mm x (5004000) mm | Ti: Bal., N: ≤0.05%, C: ≤0.08%, H: ≤0.015%, Fe: ≤0.5%, O: ≤0.4% | ≥580 | ≥15 | ≥25 |

| GR5 | (3.0200) mm x (5004000) mm | Ti: Bal., N: ≤0.05%, C: ≤0.08%, H: ≤0.015%, Fe: ≤0.4%, O: ≤0.2%, Al: ≤0.2%, V: 5.56.75%, Mo: 3.54.5% | ≥895 | ≥10 | ≥25 |

| GR5ELI | Customizable | Ti: Bal., (Other elements within standard ranges) | ≥825 | ≥8 | ≥15 |

| GR7 | (3.0200) mm x (5004000) mm | Ti: Bal., N: ≤0.03%, C: ≤0.08%, H: ≤0.015%, Fe: ≤0.3%, O: ≤0.25%, Pd: 0.12~0.25% | – | – | – |

| GR9 | Customizable | Ti: Bal., (with specific ranges for other elements) | – | – | – |

| GR12 | Customizable | Ti: Bal., N: ≤0.03%, C: ≤0.08%, H: ≤0.015%, Fe: ≤0.3%, O: ≤0.25%, Ni: 0.20.4%, Mo: 0.60.9% | – | – | – |

| TA1 | Customizable | Ti: ≥99.5%, O: ≤0.18%, N: ≤0.03%, C: ≤0.08%, Fe: ≤0.2%, H: ≤0.015% | 240 (min) | – | – |

Please note that the above specifications are typical and may vary slightly based on the manufacturer, production batch, and specific application requirements. For precise specifications and availability, it is recommended to consult with a supplier or manufacturer of Titanium alloy bars. Huaxiao Metal Manufacturer also provides other shapes of Precision products, such as plate&sheet, coil, strip, tube&pipe, wire&mesh .The price is affordable and suitable.

What are the Benefits?

Titanium alloy bars are renowned for their high strength-to-weight ratio, excellent corrosion resistance, and stability at high temperatures. They also offer good biocompatibility, low thermal conductivity, and excellent fatigue strength. These properties, combined with their workability and formability, make titanium alloy bars a versatile and valuable material for various industries. These benefits make titanium alloy bars a valuable material choice for numerous industries and applications.Welcome to Huaxiao Metal Manufacturer to request the price, trust you can be satisfied in the alloy products and buy our products in quickly. Our services are in providing comprehensive and support to clients.

Titanium Alloy Bar Applications and Uses

Huaxiao Metal Supplier provides all kinds of titanium alloy bar in the world. Welcome to inquiry and ask for the price.

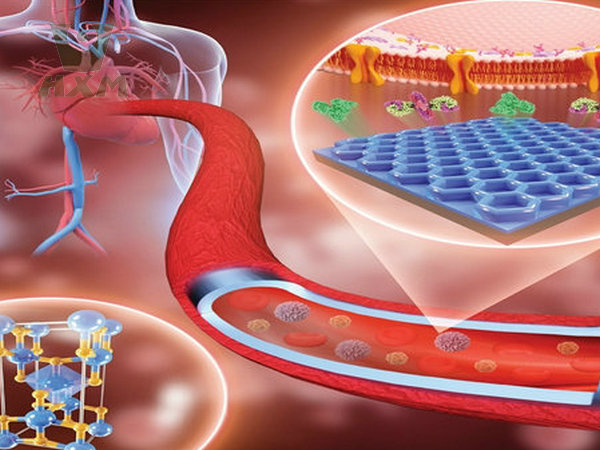

Medical Industry:

- Implants: Titanium alloy bars are highly biocompatible and corrosion-resistant, making them ideal for surgical implants such as bone screws, plates, and joint replacements.

- Dental Applications: They are also used in the manufacture of dental implants and orthodontic appliances due to their ability to integrate well with human tissue.

Marine Industry:

- Shipbuilding: Titanium alloy bars are used in the construction of ship hulls and other components due to their corrosion resistance in seawater environments.

- Oil and Gas Equipment: They are also utilized in the manufacture of equipment for oil and gas exploration, including drilling rigs and subsea components.

Chemical Industry:

- Process Equipment: Titanium alloy bars are employed in the construction of reactors, pipes, heat exchangers, and valves in chemical processing plants due to their resistance to a wide range of corrosive chemicals.

Titanium Alloy Bar Advantages

High Strength-to-Weight Ratio:

Titanium alloy bars offer exceptional strength while being relatively lightweight, making them ideal for applications where weight reduction is crucial, such as aerospace and automotive industries.

Excellent Corrosion Resistance:

They exhibit superior resistance to a wide range of corrosive environments, including saltwater, acids, and alkalis, which extends their service life and reduces maintenance requirements.

High Temperature Stability:

Titanium alloys maintain their mechanical properties and strength at elevated temperatures, making them suitable for high-temperature applications in industries like aerospace and energy.

Good Biocompatibility:

Due to their non-toxic and non-allergenic properties, titanium alloy bars are widely used in medical implants such as orthopedic devices and dental implants.

Low Thermal Conductivity:

Titanium has a lower thermal conductivity compared to many other metals, which can be beneficial in applications where heat transfer needs to be minimized.

Excellent Fatigue Strength:

They can withstand repeated stress cycles without failing, making them reliable for components subject to fatigue loading.

Workability and Formability:

Titanium alloy bars can be machined, forged, and welded into various shapes and sizes, offering versatility in manufacturing processes.

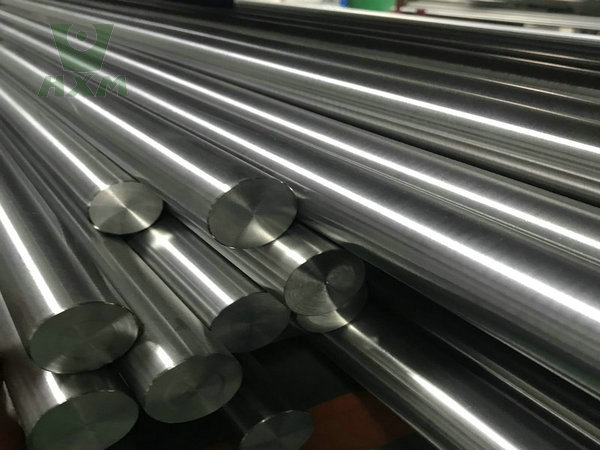

Alloy Factory

Huaxiao Metal Supplier provides professional services and reasonable prices, offering customers the best quality products. The Titanium Alloy Factory is a specialized manufacturing facility dedicated to the production of high-quality titanium alloy bars. This factory combines advanced technology, rigorous quality control, and experienced personnel to ensure the production of titanium alloy bars that meet the highest standards.The factory is equipped with state-of-the-art production equipment and machinery, capable of producing titanium alloy bars with precise dimensions and consistent quality. Welcome to require, and ask to the price.

You ask, we answer

We can provide small titanium alloy plate samples for you to check the quality. The sample is free, you only need to pay the shipping cost.

Precision alloy and titanium differ in composition, properties, and applications. Precision alloy is a specialized type of alloy material with various physical properties tailored for specific applications, while titanium is a lightweight, strong, corrosion-resistant metal widely used in aerospace, medical, and marine applications.

Titanium alloy is a versatile material with a wide range of applications due to its unique combination of properties.Titanium has a high affinity for oxygen atoms, forming a thin, dense oxide layer (TiO2) on its surface in room temperature atmospheric conditions, contributing to its exceptional corrosion resistance. It resists pitting, acid attack, stress corrosion, and has good resistance to alkalis, chlorides, chlorine-containing organic compounds, nitric acid, and sulfuric acid.