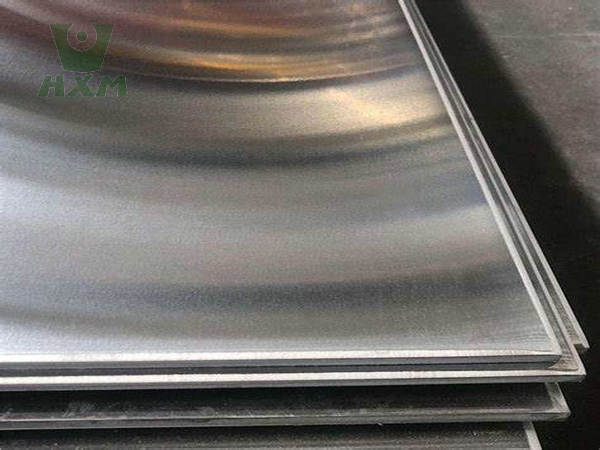

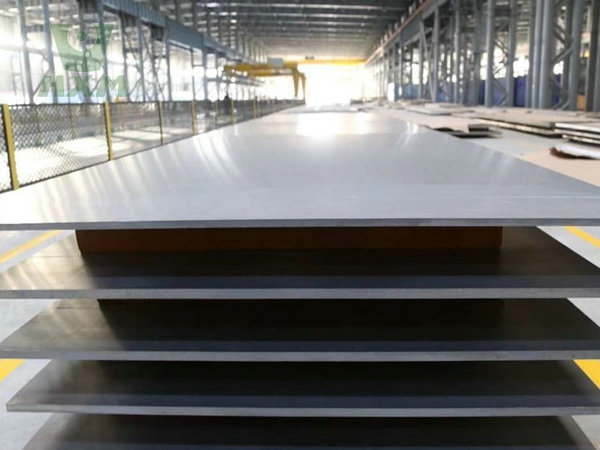

Precision TC4&GR5 Plate&Sheet, please note that the above table, Huaxiao Metal Supplier Manufacturer Exporter provides a range of standard thicknesses, widths, and lengths for Precision Alloy.

- Dimensions:

- Thickness : 1 mm -150 mm

- Width: 50mm – 2000mm

- Length: 100mm – 6000mm

- Certification: ISO, SGS, BV and so on.

- *Customized size needs to be confirmed with us

- Finish: Bright, Polishing, Mirror, Hairline, Pickled, Peeled, Black

- Certification: ISO, SGS, BV and so on.

- Payment Term:L/C at sight, T/T, West Union ,

- Package:Export wooden pallets, Craft paper, Anti-Blushing Agent.

Precision TC4 (GR5) alloy plate sheet alloy is a highly valued material in various engineering fields due to its exceptional combination of properties. This alloy, known for its high strength, corrosion resistance, good low-temperature performance, and lightweight characteristics, offers a versatile solution for numerous applications. TC4 (GR5) titanium alloy is widely recognized for its ability to maintain structural stability and reliability under extreme conditions.

Precision TC4 (GR5) Plate Data Sheets

Huaxiao Metal Supplier provides all sizes of Precision alloy plate&sheet for sale. Customized specifications are available upon request. Additionally, the exact chemical composition and mechanical properties may vary slightly within the ranges listed, depending on the specific alloy formulation and production process. Custom sizes are also available upon request. Welcome to inquire, and learn about more details about the alloy plate.

TC4 (GR5) titanium alloy plate sheet is produced to meet stringent specifications, ensuring consistent quality and performance. The typical chemical composition and mechanical properties of this alloy are carefully controlled to meet industry standards.

| Alloy Specification | Data |

|---|---|

| Alloy Name | TC4 (GR5) |

| Tensile Strength (σb) | ≥895 MPa |

| Yield Strength (σ0.2) | ≥825 MPa |

| Density | 4.51 g/cm³ |

Chemical Composition of Precision TC4 (GR5) Sheet Alloy

The chemical composition of TC4 (GR5) titanium alloy plate sheet is carefully balanced to provide optimal performance. The primary elements include titanium, aluminum, vanadium, and trace amounts of other elements to enhance specific properties. The exact composition may vary slightly depending on the manufacturing process and intended application.

The chemical composition of TC4 (GR5) alloy is as follows:

| Element | Composition (%) |

|---|---|

| Titanium (Ti) | Balance |

| Aluminum (Al) | 5.5 – 6.75 |

| Vanadium (V) | 3.5 – 4.5 |

| Iron (Fe) | ≤ 0.30 |

| Oxygen (O) | ≤ 0.20 |

| Carbon (C) | ≤ 0.08 |

| Nitrogen (N) | ≤ 0.05 |

| Hydrogen (H) | ≤ 0.015 |

This composition ensures optimal mechanical properties and corrosion resistance.

Physical Properties of Precision TC4 (GR5) Plate

TC4 (GR5) titanium alloy exhibits several notable physical properties. Its density is relatively low, making it an excellent choice for applications requiring lightweight materials. Additionally, this alloy has good thermal conductivity and electrical conductivity, although these properties are not as prominent as its mechanical characteristics.

The physical properties of TC4 (GR5) alloy include:

| Property | Value |

|---|---|

| Density | 4.43 g/cm³ |

| Melting Point | 1604 – 1660°C |

| Thermal Conductivity | 6.7 W/m·K |

| Electrical Resistivity | 1.78 µΩ·m |

| Modulus of Elasticity | 110 GPa |

| Coefficient of Thermal Expansion | 8.6 x 10⁻⁶ /°C |

These properties make TC4 (GR5) alloy suitable for high-temperature and high-stress applications.

Mechanical Properties of Precision TC4 (GR5) Plate

The mechanical properties of TC4 (GR5) titanium alloy plate sheet are impressive. With high tensile and yield strengths, this alloy can maintain structural integrity under significant loads. Its good ductility and toughness allow it to withstand deformation and impact without failing. Furthermore, TC4 titanium alloy maintains its mechanical properties at low temperatures, making it suitable for extreme environments.

The mechanical properties of TC4 /GR5 alloy are as follows:

| Property | Value |

|---|---|

| Tensile Strength | 895 – 930 MPa |

| Yield Strength | 825 – 869 MPa |

| Elongation | 10 – 15% |

| Hardness | 334 HV |

| Fatigue Strength | 500 MPa |

These properties highlight the alloy’s ability to withstand significant mechanical stress while maintaining structural integrity.

Please note that the above specifications are typical and may vary slightly based on the manufacturer, production batch, and specific application requirements. For precise specifications and availability, it is recommended to consult with a supplier or manufacturer of Precision alloy plates. Huaxiao Metal Manufacturer also provides other shapes of Precision products, such as bar, coil, strip, tube&pipe, wire&mesh. The price is affordable and suitable.

What are the TC4 (GR5) Sheet Alloy Benefits?

Precision alloy plates offer a range of benefits that make them ideal for various applications in different industries. Precision alloy plates offer a range of benefits that make them an excellent choice for various applications in different industries. Their high precision, excellent physical and mechanical properties, versatility, durability, corrosion resistance, lightweight strength, and cost-effectiveness make them a valuable material for a wide range of uses. Welcome to Huaxiao Metal Manufacturer to request the price, trust you can be satisfied in the alloy products and buy our products. Our company has the good service and the good quality alloy around the world, of course the experts will freely slove.

Precision TC4 /GR5 Plate Applications and Uses

Huaxiao Metal Supplier provides all kinds of precision alloy plate in the world. Welcome to inquiry and ask for the price.

High Strength-to-Weight Ratio: Ideal for aerospace and automotive applications where weight reduction is critical.

Corrosion Resistance: Excellent resistance to seawater, chlorides, and acidic environments.

Biocompatibility: Suitable for medical implants and surgical instruments.

Durability: Long service life even in harsh conditions.

Weldability and Formability: Easily fabricated into complex shapes and structures.

Tips for Procurement and Cost-Effectiveness

Supplier Reputation: Choose suppliers with certifications like ISO 9001 and a proven track record in titanium alloy manufacturing.

Customization: Opt for suppliers offering tailored dimensions and finishes to reduce material waste.

Bulk Purchasing: Consider bulk orders to leverage economies of scale.

Quality Assurance: Ensure the supplier provides material test certificates (MTCs) and complies with international standards.

Alloy Procurement and Cost-Effectiveness

TC4 (GR5) alloy is a premium material, but its long-term benefits often outweigh the initial costs. Factors influencing cost include:

Raw Material Prices: Fluctuations in titanium, aluminum, and vanadium prices.

Manufacturing Process: Precision machining and quality control add to the cost.

Market Demand: High demand in aerospace and medical sectors can drive prices up.

Precision TC4 /GR5 Plate Advantages

- High Strength and Durability: TC4 (GR5) titanium alloy offers exceptional strength and durability, making it suitable for high-load applications.

- Corrosion Resistance: This alloy is highly resistant to corrosion in various environments, ensuring long-term performance and reliability.

- Good Low-Temperature Performance: TC4 titanium alloy maintains its mechanical properties at low temperatures, making it ideal for extreme environments.

- Lightweight: With a density of only 4.51 g/cm³, this alloy is lightweight and energy-efficient.

Manufacturing and Cost

The manufacturing process involves:

Melting and Casting: Vacuum arc remelting (VAR) to ensure purity.

Hot and Cold Rolling: To achieve desired thickness and surface finish.

Heat Treatment: Annealing to enhance mechanical properties.

Quality Testing: Ultrasonic testing, tensile testing, and chemical analysis.

Costs are influenced by energy consumption, labor, and advanced equipment required for precision manufacturing.

Pricing Insights

The price of TC4 (GR5) alloy plates and sheets varies based on:

Thickness and Dimensions: Thicker and larger sheets cost more.

Surface Finish: Polished or coated sheets are priced higher.

Order Volume: Bulk orders typically receive discounts.

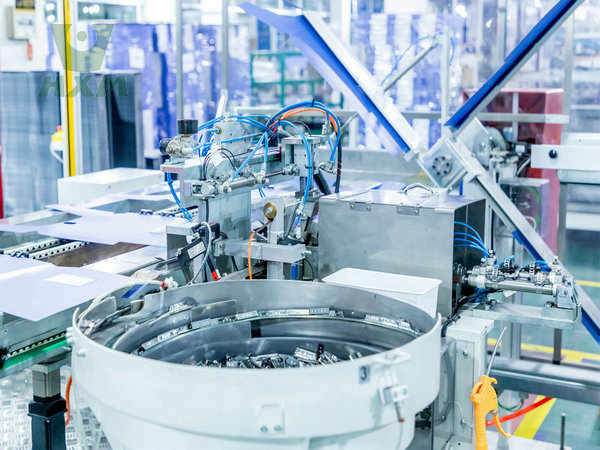

TC4 (GR5) Alloy Factory

Huaxiao Metal Supplier provides professional services and reasonable prices, offering customers the best quality products. The Precision Alloy Plate Alloy Factory is a specialized manufacturing facility dedicated to the production of high-quality precision alloy sheets. This factory combines advanced technology, rigorous quality control, and experienced personnel to ensure the production of precision alloy sheets that meet the highest standards.The factory is equipped with state-of-the-art production equipment and machinery, capable of producing precision alloy plates with precise dimensions and consistent quality.Welcome to require, and ask to the price.

Comparative Analysis Table: TC4 (GR5) vs. Other Titanium Alloys

| Property | TC4 (GR5) | Ti-6Al-2Sn-4Zr-2Mo | Ti-3Al-2.5V |

|---|---|---|---|

| Tensile Strength (MPa) | 895 – 930 | 900 – 1050 | 620 – 760 |

| Yield Strength (MPa) | 825 – 869 | 830 – 950 | 520 – 690 |

| Density (g/cm³) | 4.43 | 4.54 | 4.48 |

| Corrosion Resistance | Excellent | Excellent | Good |

| Applications | Aerospace, Medical | Aerospace, Jet Engines | Hydraulic Systems |

This table highlights the superior strength and versatility of TC4 (GR5) alloy compared to other titanium alloys.

Why Choose Us?

Precision TC4 (GR5) titanium alloy plate sheet is a versatile material with numerous benefits across various industries. Its high strength, corrosion resistance, good low-temperature performance, and lightweight characteristics make it an excellent choice for demanding applications. By understanding the alloy’s specifications, procurement tips, and cost-effectiveness, you can make informed decisions to maximize its benefits in your projects. The detailed analysis and data provided in this product introduction offer a comprehensive understanding of TC4 (GR5) titanium alloy plate sheet, making it easier to select and use this material effectively.

Precision TC4 (GR5) alloy plates and sheets are a versatile and high-performance material suitable for a wide range of industries. Their exceptional mechanical properties, corrosion resistance, and biocompatibility make them indispensable in demanding applications. By partnering with a reliable supplier and optimizing procurement strategies, businesses can achieve cost-effectiveness without compromising on quality. Whether for aerospace, medical, or industrial use, TC4 (GR5) alloy delivers unmatched performance and durability.

Strong Manufacturing Strength: Advanced equipment and experienced engineers ensure high product quality.

Strict Quality Assurance: Every TC4 (GR5) plate meets international standards like ASTM B265.

Competitive Pricing: Direct factory supply offers cost-effective solutions.

Fast Delivery: Efficient production and logistics for timely global shipping.

Customized Solutions: Tailored thickness, size, and surface finish to match your exact requirements.

FAQ

Can you provide samples?

For small parts, we can provide free samples of regular sizes, but the shipping costs must be borne by you. For large samples, we will include it in the order amount. Please confirm with our sales department according to your specific requirements.

Is there a difference between TC4 and GR5?

TC4 and GR5 refer to the same titanium alloy—Ti-6Al-4V, composed of approximately 90% titanium, 6% aluminum, and 4% vanadium. “TC4” is the Chinese designation, while “Grade 5” or “GR5” is the international (mainly ASTM) designation. Both terms describe the same material with identical chemical composition and mechanical properties.

What is the functions of precision alloy?

Precision alloys are specially engineered metals designed for high accuracy and stability in critical applications. Their main functions include maintaining consistent electrical resistance, magnetic properties, and thermal expansion under varying conditions. These alloys are essential in electronics, sensors, aerospace, and instrumentation where performance reliability is crucial.

How long is your delivery time?

It is usually 35 days, but it is also affected by your specific requirements or order quantity.

What is the minimum order quantity?

Our minimum order quantity is 100kg. Larger quantity, lower price.

How do you control product quality?

From raw material selection to packaging for transport, each production step undergoes rigorous testing and evaluation. Only products that pass all tests are approved for export.