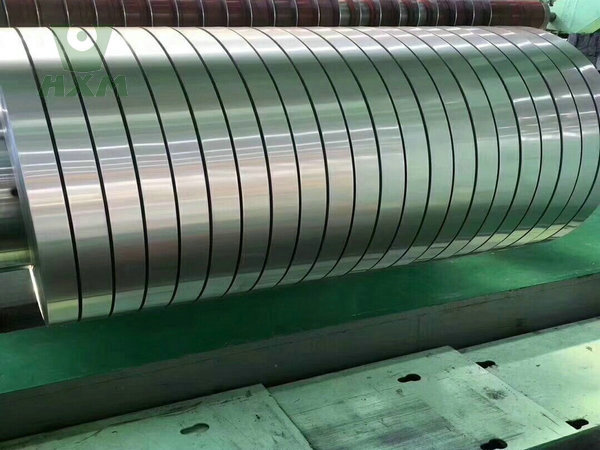

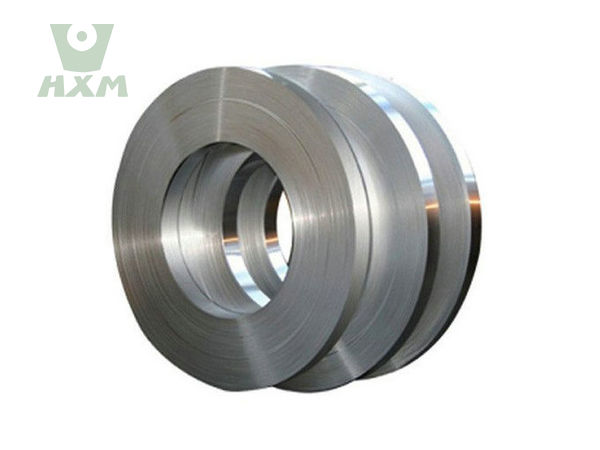

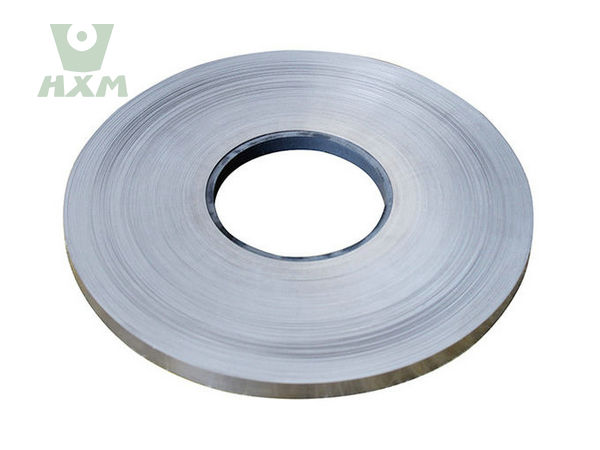

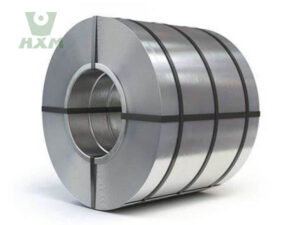

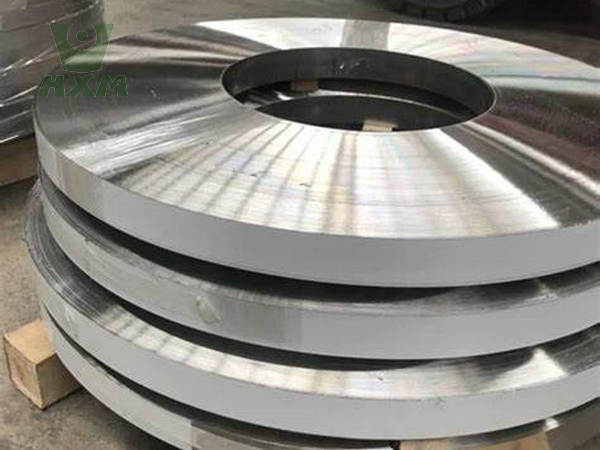

Precision Kovar 4J29 Strip Alloy, please note that the above table provides a range of standard thicknesses, widths, and lengths for Precision Alloy.

- Dimensions:

- Thickness: 1 mm -150 mm

- Width: <600mm

- Certification: ISO, SGS, BV and so on.

- *Customized size needs to be confirmed with us

- Grades: 1J22 soft magnetic alloy, 1J50 soft magnetic alloy, 1J79 Permalloy, 1J85 Permalloy, 4J32(Super-Invar), 4J36, 4J29 Kovar alloy, 4J42Kovar alloy, Cobalt-based elastic alloy 3J21, 6026, 6J22, 50HXC.

Precision Kovar 4J29 Strip Alloy Size And Specifications

Precision Kovar 4J29 Strip Alloy is a high-performance aluminum alloy specifically designed to meet the demands of various industrial applications. Kovar 4J29 is a nickel-cobalt-ferrous alloy specifically engineered for precision-matched thermal expansion with borosilicate glass and ceramics. This controlled-expansion alloy is indispensable in hermetic sealing applications for electronic packaging, aerospace components, and high-vacuum systems.

Key Characteristics:

✔ Controlled thermal expansion (CTE 4.6-5.2×10⁻⁶/°C, 20-400°C)

✔ Excellent glass-sealing compatibility (matches Pyrex® 7740)

✔ High-temperature stability up to 450°C

✔ Superior hermeticity (<1×10⁻⁹ atm·cc/s He leak rate)

✔ Good machinability and weldability

Huaxiao Metal Supplier provides all sizes of Precision alloy strip for sale. Customized specifications are available upon request. Additionally, the exact chemical composition and mechanical properties may vary slightly within the ranges listed, depending on the specific alloy formulation and production process. Custom sizes are also available upon request. Welcome to inquire, and learn about more details about the alloy strip.

| Parameter | Specification |

|---|---|

| Standard | ASTM F15, GB/T 15018 |

| Forms Available | Cold-rolled strip, foil, wire |

| Thickness Range | 0.05mm – 3.0mm (±0.002mm tolerance) |

| Width Range | 1mm – 300mm (±0.01mm tolerance) |

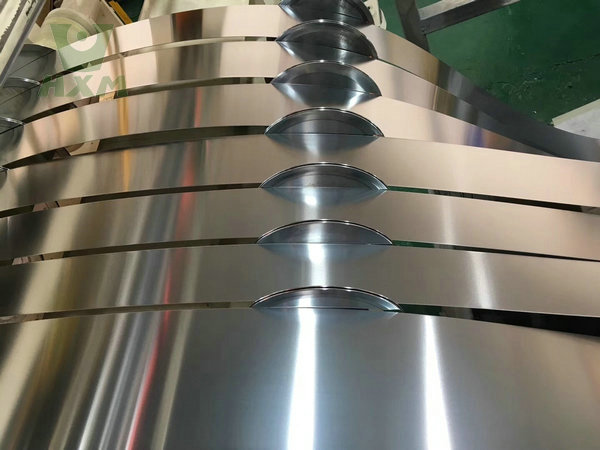

| Surface Finish | Bright annealed, pickled, or polished (Ra<0.2μm) |

| Certification | RoHS, REACH, MIL-STD-883 |

Chemical Composition of Precision Kovar 4J29 Strip

| Element | Ni | Co | Fe | Mn | Si | C | Others |

|---|---|---|---|---|---|---|---|

| 4J29 | 28.5-29.5 | 16.8-17.8 | Bal. | ≤0.50 | ≤0.30 | ≤0.03 | ≤0.25 |

Critical Composition Features:

Ni-Co-Fe balance controls CTE

Low carbon prevents carbide precipitation during sealing

Manganese improves hot workability

The chemical composition of Kovar 4J29 alloy is meticulously controlled to achieve the desired properties. The typical composition includes:

- Nickel (Ni): 28.5%–29.5%

- Cobalt (Co): 16.8%–17.8%

- Iron (Fe): Balance

- Minor Elements: Silicon (Si) ≤ 0.30%, Manganese (Mn) ≤ 0.50%, Carbon (C) ≤ 0.03%, Phosphorus (P) ≤ 0.020%, Sulfur (S) ≤ 0.020%

This composition ensures that the alloy exhibits the necessary thermal expansion characteristics, mechanical strength, and corrosion resistance required for its intended applications.

Physical Properties of Precision Kovar 4J29 Strip

| Property | Value |

|---|---|

| Coefficient of Thermal Expansion (CTE) | (4.6–5.2) × 10⁻⁶/°C (20–400°C) |

| Melting Point | ~1450°C |

| Density | ~7.85 g/cm³ |

| Electrical Resistivity | 0.48 μΩ·m |

| Thermal Conductivity | 20.6 W/(m·K) at 100°C, 5.3 W/(m·K) at 500°C |

| Specific Heat Capacity | 440 J/(kg·K) at 0°C, 649 J/(kg·K) at 430°C |

The low CTE of Kovar 4J29 alloy closely matches that of hard glasses and ceramics, ensuring minimal thermal stress during temperature cycling. Its high melting point and good thermal conductivity make it suitable for high-temperature applications, while its electrical resistivity is suitable for electronic components.

CTE Comparison with Sealing Materials:

| Material | CTE (×10⁻⁶/°C) | Match Quality |

|---|---|---|

| 4J29 Kovar | 4.9 | Reference |

| Pyrex 7740 | 3.25 | Excellent |

| Alumina Ceramic | 6.5-8.0 | Good |

| Stainless Steel 304 | 17.3 | Poor |

Mechanical Properties of Precision Kovar 4J29 Strip

| Property | Value |

|---|---|

| Tensile Strength | 450–500 MPa |

| Yield Strength | ~300 MPa |

| Hardness | ~150 HB |

| Elongation | ~20% |

| Fracture Toughness | >35 J/cm² |

Kovar 4J29 alloy exhibits high strength, good ductility, and excellent toughness, making it suitable for applications requiring both structural integrity and resistance to mechanical stress. Its good cold and hot workability allows for the fabrication of complex shapes and precise dimensions.

| Condition | Tensile (MPa) | Yield (MPa) | Elongation (%) | Hardness (HV) |

|---|---|---|---|---|

| Annealed | 520-580 | 340-390 | 30-35 | 140-160 |

| Half-Hard | 650-720 | 600-650 | 12-15 | 190-210 |

| Full-Hard | 780-850 | 750-800 | 5-8 | 240-260 |

Please note that the above specifications are typical and may vary slightly based on the manufacturer, production batch, and specific application requirements. For precise specifications and availability, it is recommended to consult with a supplier or manufacturer of Precision alloy strips. Huaxiao Metal Manufacturer also provides other shapes of Precision products, such as bar, sheet&plate, coil, tube&pipe, wire&mesh. The price is affordable and suitable.

Tips for Procurement and Cost-Effectiveness

When procuring Kovar 4J29 strip alloy, consider the following tips to ensure cost-effectiveness:

- Supplier Selection: Choose reputable suppliers with a proven track record in producing high-quality Kovar 4J29 alloy. Look for suppliers that offer competitive pricing, reliable delivery, and excellent customer service.

- Quantity Discounts: Take advantage of quantity discounts offered by suppliers when purchasing larger quantities of the alloy. This can significantly reduce the cost per unit.

- Quality Assurance: Ensure that the alloy meets the required specifications and quality standards. Request certifications and test reports from the supplier to verify the alloy’s properties.

- Inventory Management: Implement effective inventory management practices to minimize waste and reduce storage costs. Purchase only the required quantity of the alloy and avoid overstocking.

What are the Precision Kovar 4J29 Strip Benefits?

Precision Kovar 4J29 strips offer a multitude of benefits due to their unique physical and mechanical properties. Precision alloy strips offer a combination of unique physical and mechanical properties, versatility in applications, and cost-effectiveness that make them an invaluable material for a wide range of industries and applications. This can significantly reduce the time-to-market for new products and enhance overall production efficiency, also has the great functions in industries. Welcome to Huaxiao Metal Manufacturer to request the price, trust you can be satisfied in the alloy products.

Precision Kovar 4J29 Strip Applications and Uses

Huaxiao Metal Supplier provides all kinds of precision alloy coil in the world. Welcome to inquiry and ask for the price.Precision Kovar 4J29 alloy is indispensable in industries requiring exact thermal expansion matching and hermetic sealing. Its controlled coefficient of thermal expansion (CTE 4.6–5.2×10⁻⁶/°C) ensures compatibility with borosilicate glass (e.g., Pyrex® 7740) and ceramics, making it ideal for:

Electronics Packaging – Used in IC (integrated circuit) packages, transistor headers, and diode housings to prevent stress fractures during thermal cycling.

Aerospace & Defense – Critical for satellite feedthroughs, RF/microwave components, and vacuum tube seals due to its ultra-low helium leak rate (<1×10⁻⁹ atm·cc/s).

Medical Devices – Ensures reliable sealing in MRI machines, pacemakers, and X-ray tubes, where non-magnetic properties (μ<1.005) are essential.

Telecommunications – Used in fiber optic packages and laser diode housings to maintain alignment under thermal stress.

Energy & Semiconductor – Applied in power electronics, solar cells, and MEMS (Micro-Electro-Mechanical Systems) for long-term stability in harsh environments.

| Industry | Application |

|---|---|

| Electronics | Electronic packaging, glass-to-metal seals, hermetic connectors, and microwave devices. |

| Aerospace | Satellite structures, rocket engines, and thermal management systems. |

| Medical | Artificial heart valves, prosthetics, and surgical instruments. |

| Industrial | Nuclear reactors, cryogenic engineering, and high-precision mechanical components. |

The unique properties of Kovar 4J29 alloy make it an ideal choice for applications requiring precise dimensional control, reliable sealing, and resistance to thermal and mechanical stress. Its excellent thermal expansion matching properties, high strength, and good corrosion resistance make it suitable for a wide range of industries.

Precision Kovar 4J29 Strip Advantages

Huaxiao Metal Manufacturer has the various alloy products and the service is customerized for every customers.

- Thermal Expansion Matching: The alloy’s CTE closely matches that of hard glasses and ceramics, ensuring reliable sealing and minimal thermal stress.

- High Strength and Toughness: Kovar 4J29 alloy offers excellent mechanical properties, providing structural integrity and resistance to mechanical stress.

- Good Corrosion Resistance: The alloy’s surface forms a dense oxide film, providing good corrosion resistance in various environments.

- Excellent Weldability and Brazability: Kovar 4J29 alloy can be easily welded or brazed to other metals, facilitating the fabrication of complex assemblies.

- Wide Temperature Range: The alloy maintains stable properties over a wide temperature range, making it suitable for applications in extreme environments.

Procurement & Cost Optimization

Cost Factor | % of Total | Optimization Strategy |

|---|---|---|

Raw Materials (Ni/Co) | 60% | Monitor LME cobalt prices |

Precision Rolling | 25% | Order >50kg batches |

Quality Testing | 10% | Share certification costs |

Logistics | 5% | Use bonded warehouses |

Price Benchmarks:

Standard strip (0.1mm): $80-120/kg

Ultra-thin foil (0.05mm): $150-200/kg

Volume discount (>200kg): 10-15% reduction

Manufacturing Considerations

Cold rolling: Requires intermediate annealing every 30% reduction

Heat treatment: 850°C±10°C in hydrogen atmosphere

Machining: Use carbide tools with slow speeds

Cleaning: Alkaline degreasing before sealing

Pricing Insights

Market Influencers:

Cobalt price volatility (35% of material cost)

Defense/aerospace demand cycles

Alternative materials development (e.g., glass-ceramic seals)

Price Trends:

2024: $90-130/kg (stable supply)

2025: Potential 5-8% increase with space industry growth

Precision Kovar 4J29 Strip Alloy Factory

Huaxiao Metal Supplier provides professional services and reasonable prices, offering customers the best quality products. The Precision Alloy Strip Alloy Factory is a specialized manufacturing facility dedicated to the production of high-quality precision alloy coils. This factory combines advanced technology, rigorous quality control, and experienced personnel to ensure the production of precision alloy strips that meet the highest standards.The factory is equipped with state-of-the-art production equipment and machinery, capable of producing precision alloy coils with precise dimensions and consistent quality. Welcome to require, and ask to the price.

| Industry | Application | Critical Requirement | 4J29 Performance |

|---|---|---|---|

| Electronics | IC packaging | CTE match | Δα<0.3×10⁻⁶/°C |

| Aerospace | Satellite feedthroughs | Hermeticity | <10⁻⁹ leak rate |

| Medical | MRI tube seals | Non-magnetic | μ<1.005 |

| Energy | Laser diode housings | Thermal cycling | 5000+ cycles |

| Telecom | Fiber optic packages | Vibration resistance | MIL-STD-883G |

In Conclusion

As technology continues to advance, the demand for Kovar 4J29 alloy is expected to grow, driving further innovations in its production and application. Kovar 4J29 remains the industry benchmark for precision glass-metal sealing due to:

Technical Advantages:

Unmatched CTE control (±0.1×10⁻⁶/°C)

Proven reliability in extreme environments

Superior manufacturability vs. alternatives

Economic Value:

Eliminates stress fractures in sealed assemblies

Reduces rework costs in high-value electronics

Enables miniaturization in advanced packaging

Recommendations:

Mandatory for all borosilicate glass sealing

Preferred for alumina ceramic joints requiring CTE gradation

Evaluate alternatives only for non-hermetic applications

Future Outlook:

Growing demand in quantum computing housings

Development of thinner foils (<0.03mm) for MEMS

Precision Kovar 4J29 Strip Alloy is a high-performance material renowned for its exceptional thermal expansion matching properties, high strength, and good corrosion resistance. Its wide range of applications in electronics, aerospace, medical, and industrial sectors makes it an indispensable material in modern manufacturing. By understanding the alloy’s properties, optimizing the procurement process, and implementing effective inventory management practices, it is possible to achieve cost savings without compromising the alloy’s quality or performance. Huaxiao Metal Has the good quality and services in processing alloy in China, our company has the customerized service for every customers and solution for you.