Precision Alloy Coil, please note that the above table provides a range of standard thicknesses, widths, and lengths for Precision Alloy.

- Dimensions:

- Thickness: 0.5mm – 50mm

- Width: >600mm

- Certification: ISO, SGS, BV and so on.

- *Customized size needs to be confirmed with us

- Grades: 1J22 soft magnetic alloy, 1J50 soft magnetic alloy, 1J79 Permalloy, 1J85 Permalloy, 4J32(Super-Invar), 4J36, 4J29 Kovar alloy, 4J42Kovar alloy, Cobalt-based elastic alloy 3J21.

Precision Alloy Coil Size And Specifications

Huaxiao Metal Supplier provides all sizes of Precision alloy coil for sale. Customized specifications are available upon request. Additionally, the exact chemical composition and mechanical properties may vary slightly within the ranges listed, depending on the specific alloy formulation and production process. Custom sizes are also available upon request. Welcome to inquire, and learn about more details about the alloy coil.

| Alloy Type | Model Specification | Chemical Composition | Performance Characteristics |

|---|---|---|---|

| 1J22 Soft Magnetic Alloy | Customized | C≤0.04%, Mn≤0.30%, Si≤0.30%, P≤0.020%, S≤0.020%, Cu≤0.20%, Ni≤0.50%, Co=49.051.0%, V=0.801.80%, Fe=Balance | High saturation magnetic induction intensity (2.4T), high Curie point (980°C), large saturation magnetostriction coefficient (60~100×10^-6), suitable for lightweight, compact aviation and aerospace electrical components |

| 1J50 Soft Magnetic Alloy | Customized | Mainly Fe and Ni, Ni content around 50%±1%, with trace amounts of Mn, Si, and Co | High permeability, low coercivity, good thermal stability and corrosion resistance, widely used in transformers, magnetic amplifiers, magnetic shielding, and electric motors |

| 1J79 Permalloy | Customized | Ni: 78.580.0%, Fe: Balance, Mo: 4.85.2%, Si: 0.30.5%, Mn: 0.40.6%, C≤0.03%, S≤0.015%, P≤0.02% | High permeability, low coercivity, excellent magnetic properties in weak magnetic fields, suitable for high-performance magnetic devices such as transformers and magnetic amplifiers |

| 1J85 Permalloy | Customized | Ni: approximately 85%, Fe: approximately 15%, may contain trace amounts of other elements such as Mo | High permeability, low hysteresis loss, good corrosion resistance, widely used in electromagnetic wave shielding, high-precision transformers, magnetic heads, and magnetic shielding materials |

| 4J32 (Super-Invar) | Customized | C≤0.05%, Si≤0.20%, P≤0.020%, S≤0.020%, Cu: 0.40.8%, Mn: 0.20.6%, Co: 3.24.2%, Ni: 31.533.0%, Fe: Balance | Low coefficient of thermal expansion, suitable for precision manufacturing, electronic packaging, and aerospace applications |

| 4J36 (Kovar Alloy) | Customized | Fe: 29%~31%, Ni: 63%~68%, Co: 0.5%~2%, with small amounts of C, Si, Mn, etc. | Extremely low coefficient of thermal expansion, excellent weldability, good mechanical properties, widely used in precision instruments, electronic packaging, and aerospace |

| 4J29 Kovar Alloy | Customized | Ni: approximately 28.5%29.5%, Co: approximately 16.8%17.8%, mainly Fe, with trace amounts of Si, Mn, Ti, Al, Cr, etc. | Good electrical conductivity, similar coefficient of thermal expansion to silicon borate hard glass, high strength and plasticity, widely used in electronics, aerospace, military, and other fields |

| 4J42 Kovar Alloy | Customized | Mainly Fe, Ni content precisely controlled at around 41.5%, Co content of approximately 0.8%, with small amounts of Si, C, Mn, S, P, etc. | Low coefficient of thermal expansion, good mechanical properties, creep resistance, oxidation resistance, and corrosion resistance, suitable for applications requiring high precision and stability |

| Cobalt-based Elastic Alloy 3J21 | Customized | Co: 39%41%, Ni: 14%16%, Cr: 19%21%, Mo: 6.5%7.5%, C≤0.03%, with Mn and Si | High elastic modulus, high strength, non-magnetic, excellent corrosion resistance, and fatigue resistance, suitable for components that require high stress, high-frequency deformation, or long-term dimensional stability |

Please note that the above specifications are typical and may vary slightly based on the manufacturer, production batch, and specific application requirements. For precise specifications and availability, it is recommended to consult with a supplier or manufacturer of Precision alloy coils. Huaxiao Metal Manufacturer also provides other shapes of Precision products, such as bar, sheet&plate, strip, tube&pipe, wire&mesh. The price is affordable and suitable.

What are the Benefits?

Precision alloy coils, or precision alloy strips, offer a range of benefits that make them suitable for various applications. precision alloy coils offer a combination of high precision, excellent physical properties, thermal and electrical stability, magnetic properties, corrosion resistance, customizability, reliability, durability, and application versatility. These benefits make them a suitable choice for a wide range of demanding applications across different industries. Welcome to Huaxiao Metal Manufacturer to request the price, trust you can be satisfied in the alloy products and buy our products in quickly.

Precision Alloy Coil Applications and Uses

Huaxiao Metal Supplier provides all kinds of precision alloy coil in the world. Welcome to inquiry and ask for the price.

- Electronics and Electrical Industry:

- Transformers and Inductors: Precision alloy coils are commonly used in transformers and inductors due to their specific magnetic properties. These alloys can provide high permeability, low coercivity, and low hysteresis loss, making them ideal for efficient energy transfer and storage in electrical circuits.

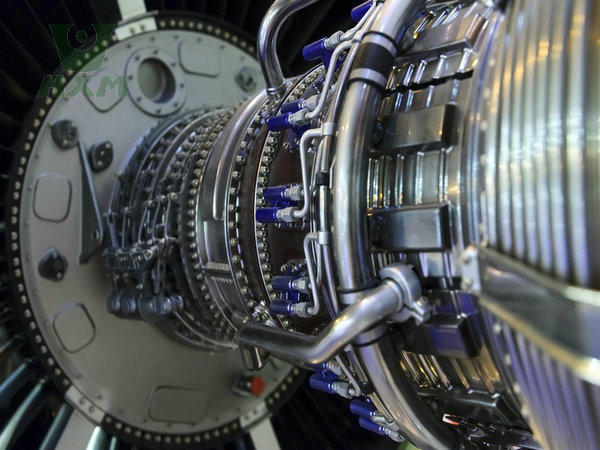

- Aerospace and Defense:

- Guidance and Control Systems: Precision alloy coils are crucial in guidance and control systems for missiles, satellites, and aircraft. They provide accurate and reliable electrical and magnetic properties, ensuring precise navigation and control.

- Thermal Management: In aerospace applications, precision alloy coils can be used in thermal management systems to regulate temperature and dissipate heat. Their high thermal conductivity and stability make them suitable for these demanding environments.

- Energy and Power Industry:

- Power Transformers: Precision alloy coils are used in power transformers for efficient energy transfer and distribution. Their high electrical conductivity and low loss characteristics make them suitable for high-power applications.

Precision Alloy Coil Advantages

High Precision:

Precision alloy coils are manufactured to tight tolerances, ensuring high accuracy in dimensions and shape.

This precision allows for consistent performance and reliability in applications where precision is critical.

Excellent Physical Properties:

Depending on the alloy composition, precision alloy coils can exhibit a wide range of physical properties such as high strength, hardness, ductility, and corrosion resistance.

These properties make them suitable for demanding environments and applications.

Thermal and Electrical Stability:

Some precision alloy coils are designed to maintain stable electrical and thermal properties over a wide range of temperatures.

This makes them ideal for applications in electronics, sensors, and other temperature-sensitive devices.

Corrosion Resistance:

Many precision alloy coils are formulated to resist corrosion from exposure to various environments.

This extends their lifespan and reduces maintenance requirements, particularly in harsh or corrosive conditions.

Customizability:

Precision alloy coils can be customized in terms of alloy composition, dimensions, and properties to meet specific application requirements.

This flexibility allows for a wide range of potential applications across different industries.

Reliability and Durability:

Due to their precise manufacturing and high-quality materials, precision alloy coils are often highly reliable and durable.

They can withstand wear and tear over extended periods, maintaining consistent performance and reducing the need for replacements.

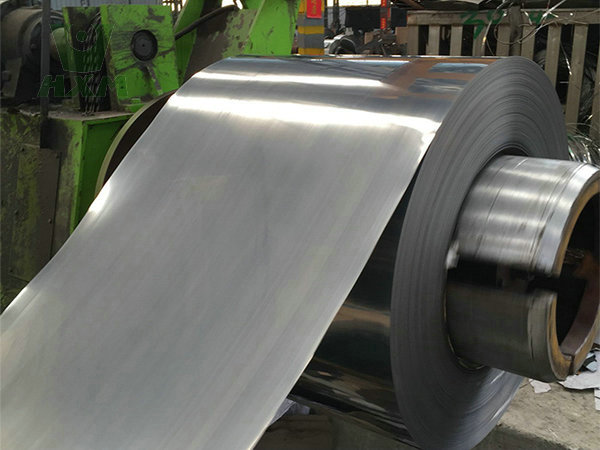

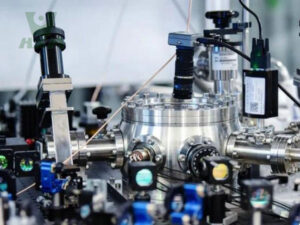

Alloy Factory

Our factories specialize in the precision engineering of alloy coils tailored for industries demanding high performance, reliability, and material integrity. Our state-of-the-art facility combines advanced metallurgical expertise with cutting-edge manufacturing techniques to produce coils crafted from specialty alloys (e.g., nickel-based, cobalt-chromium, titanium, or stainless steel) engineered for specific applications—from aerospace components requiring resistance to extreme temperatures to medical devices demanding biocompatibility and corrosion resistance.

Huaxiao Metal Supplier provides professional services and reasonable prices, offering customers the best quality products. The Precision Alloy Coil Alloy Factory is a specialized manufacturing facility dedicated to the production of high-quality precision alloy coils. This factory combines advanced technology, rigorous quality control, and experienced personnel to ensure the production of precision alloy coils that meet the highest standards.The factory is equipped with state-of-the-art production equipment and machinery, capable of producing precision alloy coils with precise dimensions and consistent quality. Welcome to require, and ask to the price.

In Conclusion

- Customized Compositions: We develop alloys with precise chemical formulations to meet unique mechanical, thermal, or electrical properties.

- Tight Tolerance Control: Our coils are manufactured with micron-level accuracy, ensuring consistent performance in critical applications.

- Innovative Processes: From vacuum induction melting to cold-rolling and annealing, we employ industry-leading methods to eliminate defects and enhance material properties.

- Certified Quality: All products undergo rigorous testing (e.g., NDT, tensile strength, fatigue analysis) and comply with international standards (ASTM, ISO, AMS).

Whether you need coils for energy storage, automotive sensors, or semiconductor manufacturing, our team of metallurgists and engineers collaborates with you to deliver solutions that optimize efficiency, reduce downtime, and extend product lifespan.

You ask, we answer

We can provide small precision alloy coil samples for you to check the quality. The sample is free, you only need to pay the shipping cost.

Precision alloy and titanium differ in composition, properties, and applications. Precision alloy is a specialized type of alloy material with various physical properties tailored for specific applications, while titanium is a lightweight, strong, corrosion-resistant metal widely used in aerospace, medical, and marine applications.

Precision alloy is a type of specialty alloy material that is engineered to exhibit precise and predictable physical properties. These alloys are designed for applications that require tight control over certain characteristics, such as magnetic, electrical, thermal, or mechanical properties.