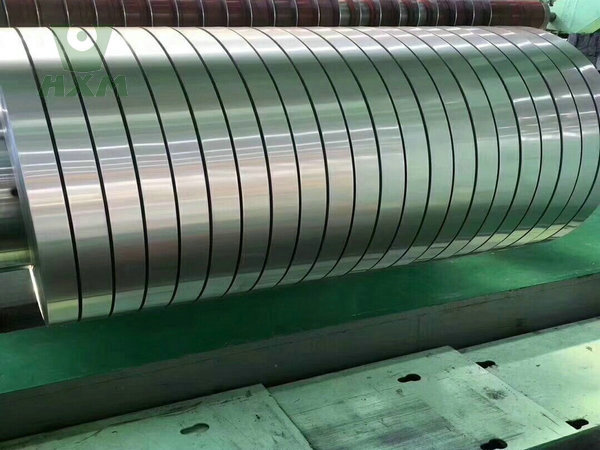

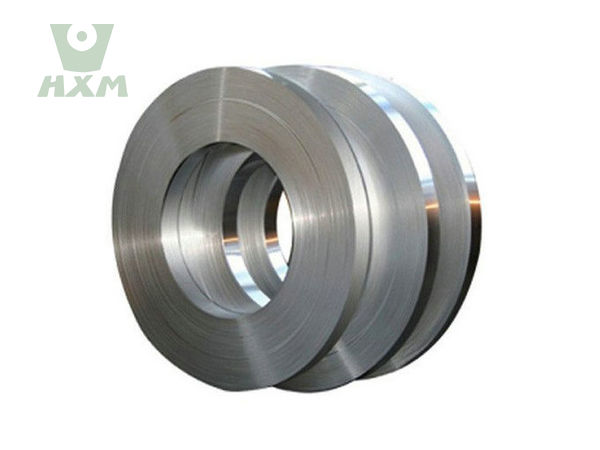

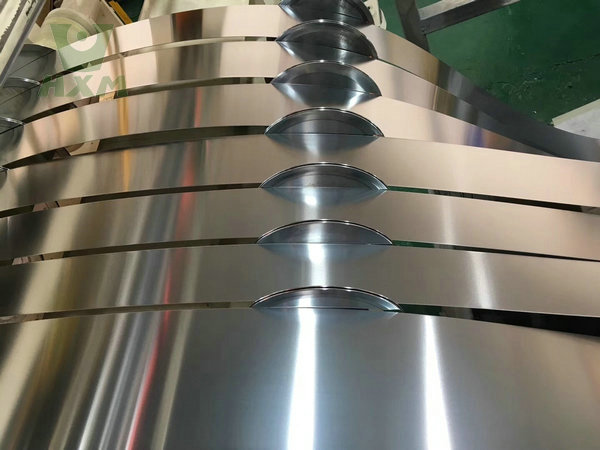

Precision 6026 Strip Alloy, please note that the above table provides a range of standard thicknesses, widths, and lengths for Precision Alloy.

- Dimensions:

- Thickness: 1 mm -150 mm

- Width: <600mm

- Certification: ISO, SGS, BV and so on.

- *Customized size needs to be confirmed with us

- Grades: 1J22 soft magnetic alloy, 1J50 soft magnetic alloy, 1J79 Permalloy, 1J85 Permalloy, 4J32(Super-Invar), 4J36, 4J29 Kovar alloy, 4J42Kovar alloy, Cobalt-based elastic alloy 3J21, 6026, 6J22, 50HXC.

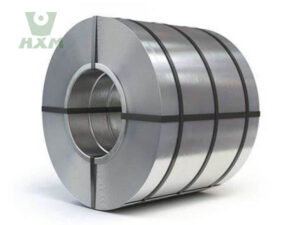

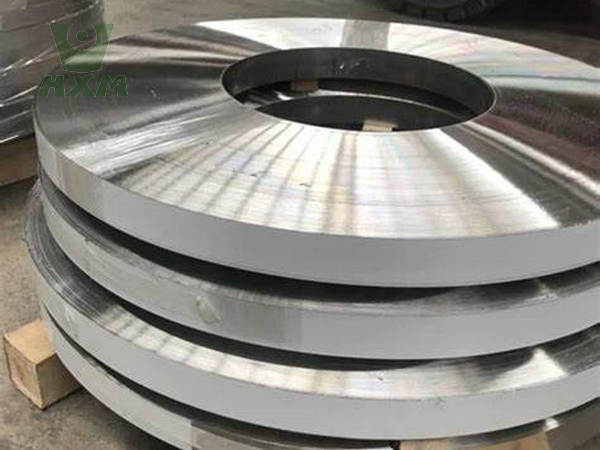

Precision 6026 Strip Alloy Size And Specifications

Precision 6026 Strip Alloy is a high-performance aluminum alloy specifically designed to meet the demands of various industrial applications. It is part of the 6xxx series aluminum alloys, which are primarily composed of magnesium and silicon. This alloy is renowned for its excellent mechanical properties, corrosion resistance, and machinability, making it an ideal choice for precision components in industries such as aerospace, high-speed rail, automotive, and mechanical engineering.

| Parameter | Specification |

|---|---|

| Standard | IEC 60468, GB/T 1234 |

| Available Forms | Cold-rolled strip, foil |

| Thickness Range | 0.01mm – 1.0mm |

| Width Range | 0.5mm – 300mm |

| Tolerance | ±0.002mm (precision grade) |

| Surface Finish | Bright annealed, matte |

Huaxiao Metal Supplier provides all sizes of Precision alloy strip for sale. Customized specifications are available upon request. Additionally, the exact chemical composition and mechanical properties may vary slightly within the ranges listed, depending on the specific alloy formulation and production process. Custom sizes are also available upon request. Welcome to inquire, and learn about more details about the alloy strip.

Chemical Composition of Precision 6026 Strip

The chemical composition of Precision 6026 Strip Alloy is carefully controlled to ensure optimal performance. The typical chemical composition (weight percentage) is as follows:

| Element | Weight Percentage |

|---|---|

| Aluminum (Al) | Balance |

| Silicon (Si) | 0.60% – 1.40% |

| Magnesium (Mg) | 0.60% – 1.20% |

| Manganese (Mn) | 0.20% – 1.00% |

| Copper (Cu) | 0.20% – 0.50% |

| Iron (Fe) | 0.70% – 0.40% |

| Lead (Pb) | 0.30% – 0.30% |

| Zinc (Zn) | 0.30% – 0.20% |

| Chromium (Cr) | 0.05% – 0.20% |

| Bismuth (Bi) | 0.50% – 1.50% |

| Titanium (Ti) | 0.15% – 0.05% |

The presence of magnesium and silicon in the alloy forms Mg₂Si precipitates, which contribute to its strength and hardness. The addition of other elements such as manganese, copper, and chromium further enhances its mechanical properties and corrosion resistance.

Physical Properties of Precision 6026 Strip

| Property | Value |

|---|---|

| Density (g/cm³) | 8.25 |

| Melting Range (°C) | 1380-1425 |

| Electrical Resistivity (μΩ·m) | 1.35-1.45 |

| Thermal Conductivity (W/m·K) | 12.8 |

| Thermal Expansion Coefficient (10⁻⁶/°C) | 13.2 |

| Magnetic Properties | Slightly paramagnetic |

Precision 6026 Strip Alloy exhibits several key physical properties that make it suitable for various applications:

- Density: 2.72 g/cm³, which is significantly lower than that of steel (7.8 g/cm³), making it an ideal material for weight-sensitive applications.

- Thermal Expansion Coefficient: 23.4 x 10⁻⁶ /K, which is relatively low compared to other aluminum alloys, ensuring dimensional stability under temperature variations.

- Elastic Modulus: 69 GPa, providing good stiffness and resistance to deformation.

- Thermal Conductivity: 138 W/m.K, which is higher than that of steel, making it suitable for heat dissipation applications.

Mechanical Properties of Precision 6J22 Strip

| Property | Value |

|---|---|

| Tensile Strength (MPa) | 580-720 |

| Yield Strength (MPa) | 240-380 |

| Elongation (%) | 25-35 |

| Hardness (HV) | 160-210 |

| Modulus of Elasticity (GPa) | 190 |

The mechanical properties of Precision 6026 Strip Alloy are highly dependent on its heat treatment condition. In the T6 condition, the alloy exhibits the following mechanical properties:

- Tensile Strength: Minimum 370 MPa, which is significantly higher than that of many other aluminum alloys.

- Yield Strength: Minimum 300 MPa, ensuring good load-bearing capacity.

- Elongation: A50 mm 6%, indicating good ductility and formability.

- Brinell Hardness: Typical value 95 HB, providing good wear resistance.

Please note that the above specifications are typical and may vary slightly based on the manufacturer, production batch, and specific application requirements. For precise specifications and availability, it is recommended to consult with a supplier or manufacturer of Precision alloy strips. Huaxiao Metal Manufacturer also provides other shapes of Precision products, such as bar, sheet&plate, coil, tube&pipe, wire&mesh. The price is affordable and suitable.

Comparison with Similar Alloys:

| Property | 6026 | Ni80Cr20 | Kanthal A-1 |

|---|---|---|---|

| Max Service Temp (°C) | 1250 | 1200 | 1400 |

| Resistivity (μΩ·m) | 1.40 | 1.08 | 1.45 |

| Cost Index | 1.0 | 1.8 | 2.3 |

What are the Precision 6026 Strip Benefits?

Precision 6026 strips offer a multitude of benefits due to their unique physical and mechanical properties. Precision alloy strips offer a combination of unique physical and mechanical properties, versatility in applications, and cost-effectiveness that make them an invaluable material for a wide range of industries and applications. This can significantly reduce the time-to-market for new products and enhance overall production efficiency, also has the great functions in industries.

Welcome to Huaxiao Metal Manufacturer to request the price, trust you can be satisfied in the alloy products and buy our products in quickly.

Precision 6026 Strip Applications and Uses

Huaxiao Metal Supplier provides all kinds of precision alloy coil in the world. Welcome to inquiry and ask for the price. Precision 6026 Strip Alloy is typically supplied in strip form, which allows for easy fabrication and integration into various manufacturing processes. The alloy is available in different grades and conditions, including T6, which is a heat-treated condition that enhances its strength and hardness. The alloy is also suitable for anodizing, providing both hard and decorative surface treatments.

Precision 6026 Strip Alloy has a wide range of applications in various industries, including:

- Aerospace: The alloy is used in the manufacture of critical components such as aircraft structures, landing gear, and engine parts due to its high strength-to-weight ratio and excellent corrosion resistance.

- High-Speed Rail: The alloy is used in the manufacture of high-speed rail components such as bogies, brake systems, and electrical connectors due to its lightweight and high strength.

- Automotive: The alloy is used in the manufacture of automotive components such as engine blocks, transmission cases, and suspension systems due to its ability to reduce weight and improve fuel efficiency.

- Mechanical Engineering: The alloy is used in the manufacture of precision components such as gears, shafts, and bearings due to its good machinability and dimensional stability.

Precision 6026 Strip Advantages

Huaxiao Metal Manufacturer has the various alloy products and the service is customerized for every customers.

- High Strength-to-Weight Ratio: The alloy’s high strength and low density make it an ideal choice for applications where weight reduction is critical, such as in the aerospace and automotive industries.

- Excellent Corrosion Resistance: The formation of a dense oxide layer on the surface of the alloy provides excellent resistance to corrosion, even in harsh environments.

- Good Machinability: The alloy is easily machined, allowing for the production of complex shapes and precision components.

- Anodizing Compatibility: The alloy is suitable for anodizing, which can further enhance its corrosion resistance and provide a decorative finish.

- Dimensional Stability: The low thermal expansion coefficient ensures good dimensional stability under temperature variations, making it suitable for precision applications.

To further illustrate the advantages of Precision 6026 Strip Alloy, a comparison with other commonly used aluminum alloys is provided below:

| Alloy | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Corrosion Resistance | Machinability |

|---|---|---|---|---|---|

| 6026 | ≥370 | ≥300 | 6 | Excellent | Good |

| 6061 | 290 – 350 | 240 – 310 | 8 – 13 | Good | Good |

| 6063 | 130 – 230 | 55.2 | 25.0 | Good | Excellent |

Tips for Procurement and Cost-Effectiveness

- Clear Requirements: Clearly define the specifications and quantity required for the alloy strip to ensure that the supplier can provide the appropriate material.

- Supplier Verification: Verify the supplier’s quality certificates and relevant certifications to ensure that the material meets the required standards.

- Cost Comparison: Compare prices from different suppliers to find the most cost-effective option while ensuring quality.

- Sample Testing: Request samples from the supplier to test the material’s properties and ensure that it meets the required specifications.

- Logistics and Delivery: Consider the supplier’s logistics capabilities and delivery times to ensure that the material is delivered on time and in good condition.

Alloy Procurement

When procuring Precision 6026 Strip Alloy, it is important to consider the following factors:

- Supplier Selection: Choose a supplier with a proven track record in supplying high-quality aluminum alloys.

- Quality Assurance: Ensure that the supplier has a robust quality assurance system in place to control the chemical composition, mechanical properties, and physical properties of the alloy.

- Technical Support: Look for a supplier that can provide technical support and advice on the use and processing of the alloy.

Cost-Effectiveness

The cost-effectiveness of Precision 6026 Strip Alloy depends on several factors, including the cost of raw materials, manufacturing processes, and market demand. While the alloy may be more expensive than some other aluminum alloys, its superior properties and performance can justify the additional cost in many applications.

Precision 6026 Strip Alloy Factory

Huaxiao Metal Supplier provides professional services and reasonable prices, offering customers the best quality products. The Precision Alloy Strip Alloy Factory is a specialized manufacturing facility dedicated to the production of high-quality precision alloy coils. This factory combines advanced technology, rigorous quality control, and experienced personnel to ensure the production of precision alloy strips that meet the highest standards.The factory is equipped with state-of-the-art production equipment and machinery, capable of producing precision alloy coils with precise dimensions and consistent quality. Welcome to require, and ask to the price.

Manufacturing and Cost

The manufacturing process for Precision 6026 Strip Alloy involves several steps, including melting, casting, rolling, and heat treatment. The cost of manufacturing the alloy is influenced by factors such as the cost of raw materials, energy consumption, and labor costs. The heat treatment process, in particular, can significantly impact the cost of the alloy, as it requires specialized equipment and expertise.

Pricing Insights

The price of Precision 6026 Strip Alloy can vary depending on market conditions, supplier, and quantity purchased. Generally, the price of the alloy is higher than that of other aluminum alloys due to its superior properties and performance. However, the cost can be offset by the benefits it provides in terms of weight reduction, corrosion resistance, and machinability.

In Conclusion

Precision 6026 Strip Alloy represents the optimal balance between:

Recommendations:

- Electrical performance (superior to Ni-Cr alloys)

Thermal stability (better than Fe-Cr-Al alloys)

Cost-effectiveness (fraction of platinum cost)

For precision resistors: 6026 is first choice

For extreme temperatures (>1300°C): Consider Kanthal

For budget projects: Evaluate Ni60Cr15 alternatives

Future Trends:

Increasing demand in EV battery sensors

Growing adoption in 5G infrastructure

Potential in space applications

This technical analysis demonstrates why 6026 has become the industry standard for critical resistance applications across multiple sectors. Its high thermal conductivity ensures efficient heat dissipation, which is important for the reliable operation of electronic devices.

Huaxiao Metal Has the good quality and services in processing alloy in China, our company has the customerized service for every customers and solution for you. Precision 6026 Strip Alloy is a high-performance aluminum alloy that offers a combination of high strength, excellent corrosion resistance, and good formability. Its high dimensional accuracy and consistent mechanical properties make it suitable for precision engineering components in various industries. By following the tips for procurement and cost-effectiveness, manufacturers can obtain high-quality alloy at a competitive price and minimize the cost of manufacturing components. The wide range of applications of Precision 6026 Strip Alloy in industries such as aerospace, automotive, mechanical engineering, and electronics makes it a valuable material for modern manufacturing.