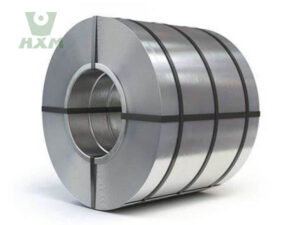

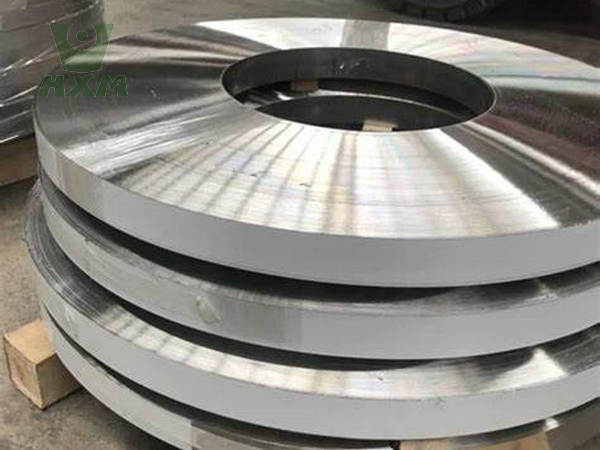

Precision 50HXC Strip Alloy, please note that the above table provides a range of standard thicknesses, widths, and lengths for Precision Alloy.

- Dimensions:

- Thickness: 1 mm -150 mm

- Width: <600mm

- Certification: ISO, SGS, BV and so on.

- *Customized size needs to be confirmed with us

- Grades: 1J22 soft magnetic alloy, 1J50 soft magnetic alloy, 1J79 Permalloy, 1J85 Permalloy, 4J32(Super-Invar), 4J36, 4J29 Kovar alloy, 4J42Kovar alloy, Cobalt-based elastic alloy 3J21, 6026, 6J22, 50HXC.

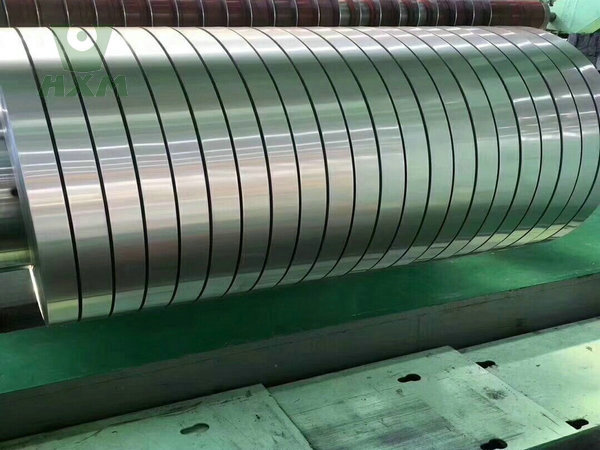

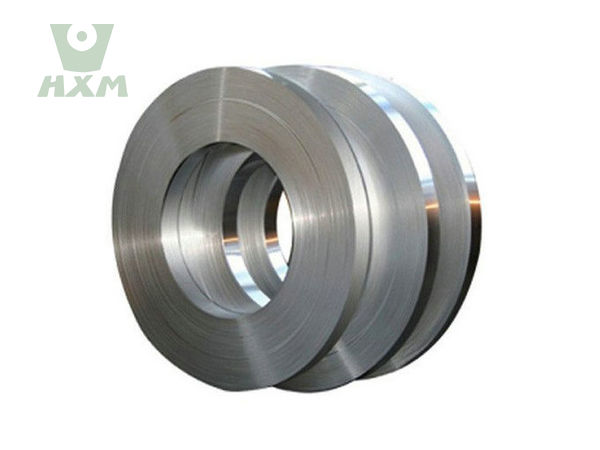

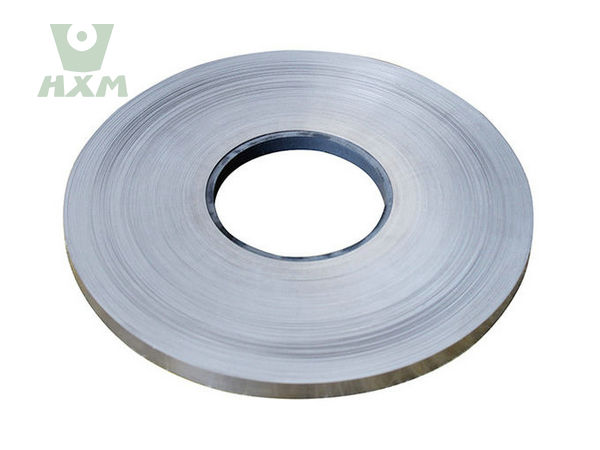

Precision 50HXC Strip Alloy Size And Specifications

Precision 50HXC Strip Alloy is a high-performance aluminum alloy specifically designed to meet the demands of various industrial applications. Precision 50HXC is a high-performance nickel-iron-chromium (Ni-Fe-Cr) resistance alloy specifically formulated for ultra-precise electrical applications. This advanced material combines exceptional resistivity stability, near-zero temperature coefficient of resistance (TCR), and superior mechanical durability, making it the premium choice for precision resistors, current sensors, and aerospace instrumentation.

Key Characteristics:

✔ Near-zero TCR (±5 ppm/°C) for unmatched stability

✔ Ultra-low resistance drift (<0.1% after 1000 hours at 150°C)

✔ Excellent thermal EMF compatibility with copper (<1 μV/°C)

✔ Optimized for thin-strip processing (0.005-0.5mm thickness)

✔ Superior corrosion resistance compared to standard manganin

Huaxiao Metal Supplier provides all sizes of Precision alloy strip for sale. Customized specifications are available upon request. Additionally, the exact chemical composition and mechanical properties may vary slightly within the ranges listed, depending on the specific alloy formulation and production process. Custom sizes are also available upon request. Welcome to inquire, and learn about more details about the alloy strip.

| Parameter | Specification |

|---|---|

| Standard | IEC 60468 Class 0.1, ASTM B344 |

| Available Forms | Precision cold-rolled strip, ultra-thin foil |

| Thickness Range | 0.005mm – 0.5mm (±0.001mm tolerance) |

| Width Range | 0.2mm – 150mm (±0.005mm tolerance) |

| Surface Roughness (Ra) | <0.1μm (mirror finish available) |

| Temper Conditions | Annealed, Hard, Extra-Hard |

Chemical Composition of Precision 50HXC Strip

The chemical composition of Precision 50HXC Strip Alloy is meticulously controlled to achieve its desired properties. The key elements and their typical ranges are as follows:

| Element | Composition Range (%) |

|---|---|

| Carbon (C) | ≤0.06 |

| Silicon (Si) | ≤1.00 |

| Manganese (Mn) | 4.0 – 6.0 |

| Phosphorus (P) | ≤0.04 |

| Sulfur (S) | ≤0.03 |

| Chromium (Cr) | 20.5 – 23.5 |

| Molybdenum (Mo) | 1.5 – 3.0 |

| Nickel (Ni) | 11.5 – 13.5 |

| Nitrogen (N) | 0.2 – 0.4 |

| Niobium (Nb) | 0.1 – 0.3 |

| Vanadium (V) | 0.1 – 0.3 |

The presence of chromium, nickel, and nitrogen is crucial for the alloy’s corrosion resistance and mechanical properties. Chromium forms a protective oxide layer on the surface, while nickel stabilizes the austenitic structure and enhances toughness. Nitrogen further strengthens the alloy by solid solution strengthening.

Physical Properties of Precision 50HXC Strip

| Property | Value | Test Standard |

|---|---|---|

| Density (g/cm³) | 8.25 | ASTM B193 |

| Electrical Resistivity (μΩ·cm) | 48.5±0.5 | IEC 60468 |

| Thermal Conductivity (W/m·K) | 19.5 | ASTM E1225 |

| Thermal EMF vs Copper (μV/°C) | 0.8 | ASTM B84 |

| Magnetic Permeability (μ) | 1.002 | ASTM A342 |

The physical properties of Precision 50HXC Strip Alloy are well-suited for a wide range of applications:

- Density: Approximately 7.9 g/cm³

- Melting Point: 1415 – 1450°C

- Thermal Expansion Coefficient: 16.2 μm/m°C (20 – 100°C)

- Specific Heat Capacity: 460 J/kg·K

- Thermal Conductivity: 14 W/m·K

- Electrical Resistivity: 0.81 Ω·mm²/m

The low thermal expansion coefficient of the alloy makes it particularly suitable for applications where dimensional stability under temperature variations is critical.

Mechanical Properties of Precision 50HXC Strip

| Temper | Tensile (MPa) | Yield (MPa) | Elongation (%) | Hardness (HV) |

|---|---|---|---|---|

| Annealed | 420-480 | 150-200 | 35-45 | 110-130 |

| Hard | 580-650 | 550-600 | 8-12 | 180-200 |

| Extra-Hard | 700-780 | 680-750 | 3-5 | 220-240 |

At room temperature (20°C), Precision 50HXC Strip Alloy exhibits the following mechanical properties:

- 0.2% Yield Strength (Rp): ≥370 N/mm²

- Tensile Strength (Rm): 700 – 950 N/mm²

- Elongation (A5): ≥35%

- Elastic Modulus: 195 kN/mm²

These properties indicate that the alloy can withstand significant mechanical stress while maintaining ductility, making it ideal for structural components in demanding environments.

Please note that the above specifications are typical and may vary slightly based on the manufacturer, production batch, and specific application requirements. For precise specifications and availability, it is recommended to consult with a supplier or manufacturer of Precision alloy strips. Huaxiao Metal Manufacturer also provides other shapes of Precision products, such as bar, sheet&plate, coil, tube&pipe, wire&mesh. The price is affordable and suitable.

Comparison with Competing Alloys:

| Property | 50HXC | Manganin | Evanohm |

|---|---|---|---|

| TCR (ppm/°C) | ±5 | ±20 | ±10 |

| Resistivity (μΩ·cm) | 48.5 | 44 | 133 |

| Thermal EMF (μV/°C) | 0.8 | 1.5 | 0.5 |

| Cost Factor | 1.0 | 0.7 | 1.8 |

What are the Precision 50HXC Strip Benefits?

Precision 50HXC strips offer a multitude of benefits due to their unique physical and mechanical properties. Precision alloy strips offer a combination of unique physical and mechanical properties, versatility in applications, and cost-effectiveness that make them an invaluable material for a wide range of industries and applications. This can significantly reduce the time-to-market for new products and enhance overall production efficiency, also has the great functions in industries.

Welcome to Huaxiao Metal Manufacturer to request the price, trust you can be satisfied in the alloy products and buy our products in quickly.

Precision 50HXC Strip Applications and Uses

Huaxiao Metal Supplier provides all kinds of precision alloy coil in the world. Welcome to inquiry and ask for the price.

Precision 50HXC Strip Alloy is used in a diverse range of industries due to its exceptional properties:

Aerospace: Used in aircraft engine components, landing gear, and structural parts due to its high strength-to-weight ratio and corrosion resistance.

Chemical Engineering: Ideal for manufacturing reactors, distillation columns, and storage tanks that are exposed to corrosive chemicals.

Marine Engineering: Applied in shipbuilding, offshore platforms, and marine propulsion systems due to its resistance to seawater corrosion.

Medical Devices: Used in surgical instruments, artificial joints, and dental implants due to its biocompatibility and corrosion resistance.

Energy Industry: Employed in nuclear power plants, oil and gas pipelines, and LNG storage systems for its high-temperature strength and corrosion resistance.

Precision Instruments: Used in the manufacture of measuring instruments, optical devices, and clock components due to its low thermal expansion.

| Industry | Application | Key Requirement | 50HXC Performance |

|---|---|---|---|

| Aerospace | Flight control sensors | ±0.005% stability | Meets MIL-STD-810 |

| Medical | MRI shim coils | Near-zero TCR | 0.002%/year drift |

| Energy | Smart grid shunts | 500A continuous | 0.1°C/W thermal rise |

| Automotive | EV current sensing | Vibration resistance | 10⁹ cycle fatigue |

| Metrology | Standard resistors | Low thermal EMF | 0.5μV/°C certified |

Precision 6026 Strip Advantages

Huaxiao Metal Manufacturer has the various alloy products and the service is customerized for every customers.

Measurement-grade precision: ±0.01% resistance tolerance achievable

Long-term stability: <50ppm annual drift in controlled environments

Superior solderability: Compatible with Sn-Ag-Cu solders

Radiation resistance: Suitable for aerospace applications

Low thermoelectric noise: Critical for sensitive instrumentation

Procurement & Cost Optimization

| Cost Component | % of Total | Optimization Strategy |

|---|---|---|

| Raw Materials | 55% | Monitor Ni futures market |

| Precision Rolling | 25% | Order >100kg batches |

| Quality Control | 15% | Share testing costs |

| Logistics | 5% | Consolidated shipments |

Price Benchmarks:

Standard strip (0.1mm): $120-150/kg

Ultra-precision foil (0.01mm): $250-300/kg

Volume discount (>500kg): 12-18% reduction

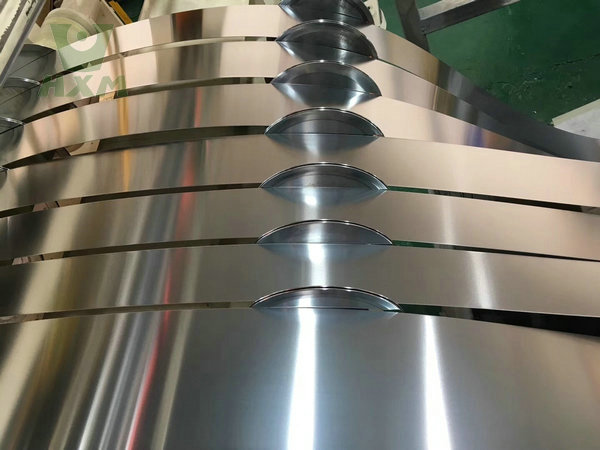

Manufacturing Considerations

Cold rolling: Requires <0.5% reduction per pass

Annealing: Hydrogen atmosphere at 850°C±10°C

Slitting: Diamond-coated tools recommended

Cleaning: Ultrasonic methanol cleaning for high-grade apps

Pricing Insights

Market Factors:

Nickel price volatility (LME monitoring essential)

Aerospace demand cycles (Q2/Q3 peak)

Alternative material developments (graphene, etc.)

Export controls on precision alloys

Price Projections:

2024: $125-160/kg (stable)

2025: Potential 8-12% increase with aerospace recovery

Procurement of Precision 50HXC Strip Alloy involves several steps:

Specification Development: Clearly define the technical requirements, including chemical composition, mechanical properties, and physical dimensions.

Supplier Selection: Identify potential suppliers through market research and request quotations. Evaluate suppliers based on price, quality, delivery time, and after-sales service.

Contract Negotiation: Finalize the terms and conditions, including payment terms, delivery schedules, and quality assurance clauses.

Order Placement and Follow-Up: Place the order and monitor the production and delivery process to ensure timely receipt of the material.

Precision Strip Alloy Factory

Huaxiao Metal Supplier provides professional services and reasonable prices, offering customers the best quality products. The Precision Alloy Strip Alloy Factory is a specialized manufacturing facility dedicated to the production of high-quality precision alloy coils. This factory combines advanced technology, rigorous quality control, and experienced personnel to ensure the production of precision alloy strips that meet the highest standards.The factory is equipped with state-of-the-art production equipment and machinery, capable of producing precision alloy coils with precise dimensions and consistent quality. Welcome to require, and ask to the price.

In Conclusion

Precision 50HXC Strip Alloy represents the pinnacle of resistance alloy technology, offering:

Technical Superiority:

Unmatched TCR stability (±5ppm/°C)

Industry-leading long-term drift performance

Excellent mechanical properties across tempers

Economic Value:

30-40% cost savings vs. precious metal alternatives

Reduced recalibration needs in precision instruments

Longer service life than standard alloys

Recommendations:

First choice for all Class 0.1 precision resistors

Essential for aerospace/defense applications

Evaluate alternatives only for cost-sensitive, lower-precision apps

Future Development:

Nanostructured versions in development (20% higher resistivity)

Potential IoT sensor market expansion

Growing demand in quantum computing applications

Precision 50HXC Strip Alloy offers a unique combination of corrosion resistance, mechanical strength, and dimensional stability, making it a versatile material for high-performance applications. By carefully considering the procurement process, optimizing manufacturing costs, and leveraging the alloy’s benefits, manufacturers can achieve significant improvements in product performance and cost-effectiveness. The alloy’s proven track record in various industries underscores its reliability and value in demanding environments. Huaxiao Metal Has the good quality and services in processing alloy in China, our company has customerized service for every customers and solution for you.