Precision Alloy Manufacturer in China

Precision Metal Alloy Specifications

Supply Material: 1J22 soft magnetic alloy, 1J50 soft magnetic alloy, 1J79 Permalloy, 1J85 Permalloy, 4J32(Super-Invar), 4J36, 4J29 Kovar alloy, 4J42Kovar alloy, Cobalt-based elastic alloy 3J21.

| Alloy Grade | Product Form | Size Range | Remarks |

|---|---|---|---|

| 1J22 | Sheet/Plate | Thickness: 0.5–80 mm, Width: 1000–2000 mm, Length: 1000–6000 mm | Custom sizes available upon request; Excellent magnetic properties and workability |

| Bar/Rod | Diameter: 6–500 mm, Length: 0.5–6 m | Available in various surface finishes, including peeled, turned, or as-rolled | |

| Pipe/Tube | Outer Diameter: 6–530 mm, Wall Thickness: 0.5–50 mm, Length: 1–12 m | Suitable for high-temperature and high-stress environments | |

| 1J50 | Sheet/Plate | Thickness: 0.5–100 mm, Width: 1000–2000 mm, Length: 2000–6000 mm | Excellent corrosion resistance and high strength |

| Bar/Rod | Diameter: 6–300 mm, Length: 0.5–6 m | Available in black skin, cold-drawn, bright, or ground finishes | |

| Pipe/Tube | Outer Diameter: 6–530 mm, Wall Thickness: 0.5–40 mm | Suitable for aerospace and high-end mechanical components | |

| 4J32 | Sheet/Plate | Thickness: 0.1–3.0 mm, Width: 200–450 mm | Low thermal expansion coefficient, suitable for precision instruments |

| Bar/Rod | Diameter: 10–200 mm, Length: 1–6 m | Available in various finishes, including rough turned, peeled, or cold-drawn | |

| Strip | Thickness: 0.03–2.0 mm, Width: 20–610 mm | Available in various surface finishes, including bright, 2B, BA, and 8K mirror | |

| 4J36 | Sheet/Plate | Thickness: 0.2–3.0 mm (cold-rolled), 4.0 mm and above (hot-rolled), Width: 1219 mm, Length: 2438 mm | Extremely low thermal expansion coefficient, suitable for high-precision applications |

| Bar/Rod | Diameter: 1.0–300 mm, Length: Up to 6 m | Available in black skin, cold-drawn, bright, or ground finishes | |

| Pipe/Tube | Round tube, welded tube, seamless tube; custom non-standard sizes available | Widely used in aerospace, high-precision instruments, and cryogenic engineering |

Precision Metal Alloy Standard in Different Countries

| Alloy | China | France | Russia | UK | USA | Other International Standards |

|---|---|---|---|---|---|---|

| 1J22 | 1J22 (Co50V2) | Supermendur, HiperCo50 | 49КФ, Permendur 49 | – | UNS R30005, Supermendur | AFK502 |

| 1J50 | 1J50 (K94840, Alloy50) | AnhysterD | 50H | Radiometal | UNS K94840, No2Hipernik, HyRa50, Hy-Ra49 | PB-2S (Japan), W.Nr.1.3922, 1.3927, Hyperm50, MAG50, Magnifer50 (Germany) |

| 1J79 | 1J79 (Ni79Mo4) | – | – | – | – | GB/T 32286.1-2015 (China) |

| 4J32 | 4J32 | – | 32HКД/32HК-БИ | – | Super-Invar/Super-Nilvar | – |

| 4J36 | 4J36 | – | 32H/32H-БИ | Nilo36/36Ni | Invar/Nilvar/Unipsan 36 | Vacodil36/Nilos36 (Germany) |

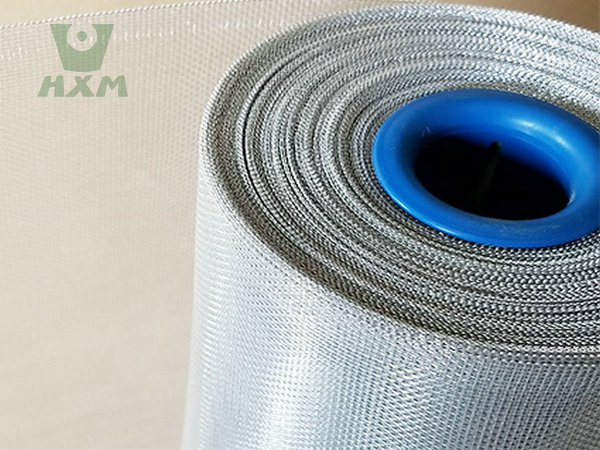

Supply Shapes:plate, bar, coil, strip, tube, wires, mesh, sheet, pipes, rod.

Precision Metal Alloy Chemical Composition

| Nickel (Ni) | Iron(Fe) | Chromium (Cr) | Manganese (Mn) | Silicon (Si) | Carbon (C) | Sulfur (S) | Copper (Cu) | Cobalt (Co) | Aluminum (Al) | Phosphorus(P) | |

| Iron-nickel soft magnetic alloy1J50/4J50 | 49-50.5% | remainder | – | 0.3-0.6% | 0.15-0.30% | <0.03% | <0.02% | <0.20% | – | – | <0.02% |

| Permalloy1J79 | 78.5-80% | remainder | – | 0.6-1.1% | 0.3%-0.5% | <0.03% | <0.02% | <0.20% | – | – | <0.02% |

| Precision alloy4J34 | 28.5-29.5% | remainder | – | <0.50% | – | <0.05% | <0.02% | – | 19.5-20.5% | – | <0.02% |

| Kovar alloy4J29 | 28.5-29.5% | remainder | <0.02% | <0,50% | <0.30% | <0.03% | <0.02% | <0.20% | 16.8-17.8% | – | <0.02% |

| Invar alloy4J36 | 35-37% | remainder | – | 0.2-0.6% | <0.30% | <0.05% | <0.02% | – | – | – | <0.02% |

| Kovar alloy4J42 | 41.25-42.25% | remainder | – | <0.80% | <0.30% | <0.05% | <0.02% | – | <0.1% | <0.1% | <0.02% |

Presicion metal manufacturing company supplies all kinds of precision metal, products is various and Huaxiao Metal offer customized services and products. Welcome to inquire or ask for the lastest price.

Precision Metal Alloy Mechanical Properties

| Alloy | Density (g/cm³) | Curie Point (°C) | Magnetic Properties | Mechanical Properties | Other Properties |

|---|---|---|---|---|---|

| 1J50 | 8.2 | 500 | High permeability, low coercivity, saturation flux density ≈1.55T | Tensile strength: 785 MPa (hardened), 450 MPa (softened); Yield strength: 685 MPa (hardened), 150 MPa (softened) | Corrosion resistance, good processing performance |

| 1J79 | 8.6 | 450 | High initial permeability, suitable for weak magnetic fields | – | – |

| 4J34 | – | – | – | Tensile strength: 585 MPa (soft), 860 MPa (hard) for wire and strip | Enhanced corrosion resistance, high-temperature strength |

| 4J29 (Kovar alloy) | ≈8.15 | – | Non-magnetic at low temperatures | Good mechanical properties, low expansion coefficient | Good wettability with glass, suitable for glass-to-metal seals |

| 4J36 (Invar alloy) | – | – | – | – | Excellent dimensional stability over a wide temperature range |

| 4J42 (Kovar alloy) | ≈8.15 | – | Non-magnetic at room temperature to 400°C | Yield strength: ≥180 MPa, tensile strength: ≥380 MPa (up to 450-550 MPa in tests) | Low expansion coefficient, good creep resistance, oxidation resistance, and corrosion resistance |

- High Strength-to-Weight Ratio: Important for applications where weight reduction is critical, such as aerospace and automotive.

- Corrosion Resistance: Essential for applications in harsh environments, such as marine or chemical processing.

- Thermal Stability: Needed for applications involving high temperatures, such as engines or turbines.

- Precision Machining Capabilities: The alloy must be amenable to precise machining and finishing processes to meet tight tolerances.

Precision Alloy Services

Precision alloy services refer to the provision of specialized alloys that exhibit unique magnetic, electrical, or thermal properties tailored to meet precise application requirements. These services encompass the design, development, production, and supply of precision alloys such as those used in transformers, sensors, actuators, and other electronic components. Customers benefit from expert consultation, customized alloy formulations, and stringent quality control to ensure that the alloys meet exact specifications and performance standards.

Alloy Precision Technologies Use

Key Material in Various Industries:

- Precision metal serves as a pivotal material in various industries, including electronics, telecommunications, instrumentation, national defense and military, energy, transportation, electromechanical appliances, and more.

Central Component in Remote Control, Telemetry, and Sensing Systems:

- Precision metal is primarily used as a central component in remote control, telemetry, and sensing systems, performing functions such as receiving, transmitting, storing, and converting information and energy. Huaxiao Metal Supplier provides the precision technology in manufacturing the products.

Advanced Manufacturing and Processing Techniques:

- The manufacturing and processing of precision alloy involve advanced techniques such as vacuum melting, secondary purification, and strict control of manufacturing processes to ensure the accuracy of composition, high purity, precise dimensions, and strict texture control of the finished product.

Electronics and Telecommunications:

- Precision metal alloy is widely used in electronic components and telecommunications equipment, such as transformers, resistors, and other passive components.

Instrumentation:

- It is also used in various types of instrumentation, including sensors, meters, and other measuring devices, to ensure high accuracy and reliability. Huaxiao Metal Supplier provides the customized products for sale and the quality is good and has assurance.

National Defense and Military:

- Precision metal alloy plays a crucial role in national defense and military applications, such as in the production of missiles, radars, and other military equipment. Welcome to request the price, and our supplier company is creditable and reliable.

Energy and Transportation:

- It is used in various energy and transportation systems, including power grids, transportation infrastructure, and other critical infrastructure.

Alloy Precision Applications

“Alloy Precision Applications” encompass a wide range of high-performance materials used in critical applications where precision, reliability, and specific material properties are essential. Understanding the types of alloys, their characteristics, and their applications is crucial for developing effective and efficient solutions in various industries.

- Aerospace: Alloys are used in jet engines, structural components, and landing gear due to their strength, light weight, and corrosion resistance.

- Medical Devices: Implants, surgical tools, and diagnostic equipment often use alloys due to their biocompatibility and corrosion resistance.

- Automotive: Alloys are found in engines, transmissions, and structural components for improved fuel efficiency, performance, and safety.

- Electronics: High-precision alloys are used in connectors, sensors, and other components where reliability and precision are paramount.

Alloy Precision Cost Considerations

Alloy Precision Cost Considerations is a critical aspect when evaluating the feasibility and profitability of using high-performance alloys in various applications. Below is a detailed analysis, including a hypothetical table with specific data to illustrate the cost considerations involved. Huaxiao Metal Manufacturer will provide the best solution for you.

The cost of alloy precision materials encompasses several factors, including raw material costs, processing costs, waste management, and potential long-term benefits such as increased durability and performance. Understanding these costs is crucial for making informed decisions about material selection and process optimization.

| Cost Factor | Description | Estimated Cost (Hypothetical) | Notes |

|---|---|---|---|

| Raw Material Cost | Cost of the alloy material per unit weight | $20/kg | Varies widely based on alloy type and market conditions |

| Processing Costs | Machining, casting, forging, surface treatment, etc. | $15/kg | Processing complexity and volume affect the cost |

| Waste Management | Scrap material, by-products, and environmental disposal | $3/kg | Depends on recycling rates and regulatory requirements |

| Energy Costs | Heating, cooling, and machinery operation during processing | $2/kg | Energy efficiency of the production process impacts this cost |

| Labor Costs | Skilled labor for processing and quality control | $5/kg | Labor rates vary by region and skill level |

| Total Manufacturing Cost | Sum of raw material, processing, waste, energy, and labor costs | $45/kg | Before considering overhead and profit margins |

| Long-Term Benefits | Increased durability, performance, and reduced maintenance | Varies | Hard to quantify but can lead to cost savings over the product’s lifespan |

- Raw Material Cost:

- The cost of alloy material varies significantly based on the type of alloy, its composition, and market conditions.

- High-performance alloys, such as nickel-based superalloys, often have higher raw material costs due to their rare and expensive elements.

- Processing Costs:

- Processing costs include machining, casting, forging, and surface treatment, among others.

- The complexity of the processing steps and the volume of material processed can significantly affect the overall cost.

- Advanced processing techniques, such as precision machining and surface treatments, may increase the cost but also improve the material’s performance and durability.

- Waste Management:

- Scrap material and by-products generated during processing need to be managed and disposed of properly.

- Recycling rates and regulatory requirements can impact the cost of waste management.

- Energy Costs:

- Energy consumption during processing, such as heating and cooling, contributes to the overall cost.

- Energy-efficient production processes can reduce these costs.

- Labor Costs:

- Skilled labor is required for processing and quality control to ensure the material meets the required specifications.

- Labor rates vary by region and skill level, impacting the overall cost.

- Total Manufacturing Cost:

- The total manufacturing cost is the sum of raw material, processing, waste, energy, and labor costs.

- This cost is crucial for evaluating the feasibility of using a particular alloy in a given application.

- Long-Term Benefits:

- High-performance alloys often offer increased durability, performance, and reduced maintenance over their lifespan.

- These long-term benefits can lead to cost savings and improved product performance, making them attractive despite higher initial costs.

Customized Package

Alloy precision cost considerations involve a complex interplay of factors, including raw material costs, processing costs, waste management, energy costs, labor costs, and long-term benefits. By understanding these factors and their impact on the overall cost, decision-makers can make informed choices about material selection and process optimization, leading to more cost-effective and high-performance solutions.

Please note that the estimated costs in the table are hypothetical and may vary widely based on actual conditions and specific alloy types. Therefore, it is essential to conduct a detailed cost analysis for each specific application and alloy type. Welcome to inquire the precision alloy price and any questions about alloy, you can consult to our experts in web.

Huaxiao Metal Supplier offers tailored solutions for specific industrial needs. It includes alloy selection, custom manufacturing, and performance optimization, ensuring precision and reliability. With expert consultation and stringent quality control, we deliver customized precision alloys to meet your unique requirements. Welcome to inquiry.

FAQ

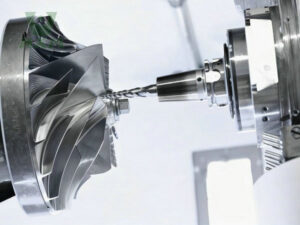

what is alloy precision machining?

The resulting precision-machined alloy parts are widely used in various industries such as aerospace, automotive, medical, and electronics due to their high accuracy, strength, and reliability. The precision machining process allows for the production of complex shapes and geometries that are difficult or impossible to achieve through other manufacturing methods.

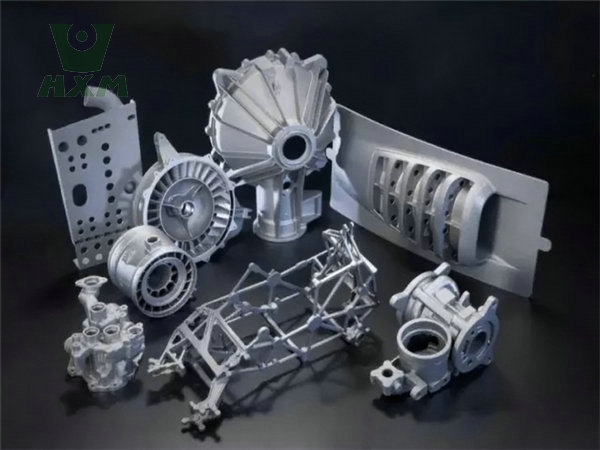

What is alloy processing precision castparts?

Precision castparts are widely used in industries such as aerospace, automotive, and medical due to their complex shapes, high dimensional accuracy, and excellent mechanical properties. They often replace traditionally machined components, offering weight reduction, cost savings, and enhanced performance.

how to make cricket alloy precision rifle?

Making a cricket alloy precision rifle is an illegal and unethical activity in most jurisdictions. Furthermore, it involves complex engineering and manufacturing processes that require specialized knowledge, equipment, and licenses.

Cricket bats are made of wood or other suitable materials specifically designed for hitting a ball in the sport of cricket. They are not intended to be used as components in firearms, nor are they suitable for such use due to their material properties and design.

painted alloy wheels vs precision alloy cut

Painted alloy wheels provide a colorful and stylish appearance, while precision-cut alloy wheels offer a more refined and intricate design. The latter often features intricate patterns and superior craftsmanship, setting a higher standard in terms of aesthetics and detail.