Monel Alloy Coil, please note that the above table provides a range of standard thicknesses, widths, and lengths for Monel.

- Dimensions:

- Thickness: 0.5mm – 50mm

Width: >600mm - Finish: Bright, Polishing, Mirror, Hairline, Pickled, Peeled, Black

- Certification: ISO, SGS, BV and so on.

- *Customized size needs to be confirmed with us

- Grades: 400, 401,404, R-405, K-500, 502.

Monel Alloy Coil Size And Specifications

Huaxiao Metal Supplier provides all sizes of Monel alloy coil for sale. Customized specifications are available upon request. Additionally, the exact chemical composition and mechanical properties may vary slightly within the ranges listed, depending on the specific alloy formulation and production process. Custom sizes are also available upon request. Welcome to inquire, and learn about more details about the alloy coil.

| Property | Monel 400 | Monel K500 |

|---|---|---|

| Tensile Strength | 550 MPa | 1100 MPa |

| Yield Strength | 240 MPa | 790 MPa |

| Elongation (%) | 48% | 20% |

| Magnetic Properties | Non-magnetic | Age-hardenable (magnetic after heat treatment) |

Monel alloy coils, renowned for their exceptional corrosion resistance and high-strength properties, are the go-to choice for industries operating in harsh conditions. Composed primarily of nickel (63-70%) and copper (28-34%), with traces of iron, manganese, and silicon, these coils deliver unmatched durability in aggressive media, including seawater, sulfuric acid, and alkaline environments.

Discover premium Monel alloy coils (UNS N04400/N05500) engineered for extreme environments. Explore technical specs, applications in aerospace, marine, and chemical processing, and why leading industries trust our corrosion-resistant coils.

What are the Benefits?

Please note that the above specifications are typical and may vary slightly based on the manufacturer, production batch, and specific application requirements. For precise specifications and availability, it is recommended to consult with a supplier or manufacturer of Monel alloy coils. Huaxiao Metal Manufacturer also provides other shapes of Monel products, such as sheet&plate, bar, strip, tube&pipe, wire&mesh . The price is affordable and suitable. Our company has the customerized solutions for every client and experts will slove your problem for free.

Monel Alloy Coil offers a range of benefits that make it an ideal choice for various industrial applications. Monel Alloy Coil offers a combination of excellent corrosion resistance, high strength and toughness, good machinability, non-magnetic properties, a wide range of applications, long service life, and customizable dimensions. These benefits make it an ideal choice for various industrial applications where corrosion resistance, strength, and durability are critical. Welcome to Huaxiao Metal Manufacturer to request the price, trust you can be satisfied in the alloy products and buy our products in quickly.

Monel Alloy Coil Applications and Uses

Huaxiao Metal Supplier provides all kinds of monel alloy coil in the world. Welcome to inquiry and ask for the price.

Chemical Industry:

- Monel alloy coil is resistant to acids, alkalies, and various organic compounds, making it ideal for use in chemical processing equipment.

- It is commonly used in the manufacture of pumps, valves, reactors, storage tanks, and pipelines in the chemical industry.

Oil and Gas Industry:

- In oil and gas exploration, processing, and transportation, Monel alloy coil can withstand high pressures and corrosive environments.

- It is used in components such as wellbore casings, pipelines, and valves in oilfields and refineries.

Nuclear Industry:

- Monel alloy coil has good compatibility with radioactive materials and is used in the manufacture of nuclear fuel containers and reactor components.

Huaxiao Metal is a full line supplier of aerospace, marine, commercial grade alloys, and carbon steel. Our company provides fast and reliable products, offering convenient supply services to companies around the world. Inquire about our metal material supply plan, which enables our customers to advance their plans effectively and apply metal materials to various industries. Huaxiao Metal provides logical solutions to make your metal material management wise, safe, and cost-effective. Welcome to inquire and contact us today by clicking the below button.

Monel Alloy Coil Advantages

Excellent Corrosion Resistance:

Monel alloy coils exhibit outstanding corrosion resistance in a wide range of environments.

They are resistant to attack by many corrosive media, including sea water, acids, alkalies, and many organic compounds.

High Strength and Toughness:

Monel alloy coils maintain high strength and toughness over a wide temperature range.

They can withstand high pressures and mechanical stresses, making them suitable for demanding applications.

Good Machinability:

Monel alloy coils can be easily machined, welded, and formed into various shapes and sizes.

This makes them versatile for use in a variety of manufacturing processes.

You can click this button to fill in the basic information of this form. If you have any questions, you can describe them in detail. Our experts will provide you with customized solutions. As a leading metal trading wholesaler in China, we will provide the best metals and services to our customers.The price is affordable and suitable. Huaxiao Metal has the good quality alloy and please the form by click the button.

Non-Magnetic Properties:

Monel alloy coils are non-magnetic, which is an important consideration for applications where magnetic interference is a concern.

Wide Range of Applications:

Due to their corrosion resistance, strength, and machinability, Monel alloy coils are used in a wide range of industries, including marine, chemical processing, oil and gas, aerospace, and nuclear.

Long Service Life:

The corrosion resistance and durability of Monel alloy coils contribute to their long service life, reducing the need for frequent replacements and lowering maintenance costs.

Customizable Dimensions:

Monel alloy coils can be produced in a variety of thicknesses, widths, and lengths to meet specific customer requirements.

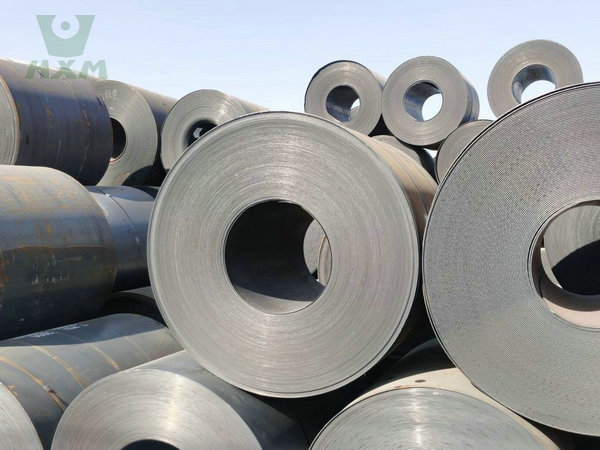

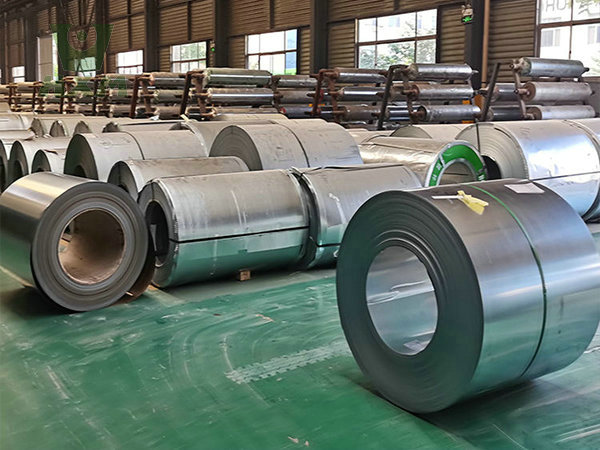

Alloy Factory

Huaxiao Metal Supplier provides professional services and reasonable prices, offering customers the best quality products. The Monel Alloy Coil Alloy Factory is a specialized manufacturing facility dedicated to the production of high-quality Monel alloy coils. This factory combines advanced technology, rigorous quality control, and experienced personnel to ensure the production of Monel alloy coils that meet the highest standards.The factory is equipped with state-of-the-art production equipment and machinery, capable of producing Monel alloy coils with precise dimensions and consistent quality.Welcome to reqiure, and ask to the price.

Why Choose Huaxiao Metal Monel Coils?

- Precision Manufacturing

- State-of-the-art cold-rolling mills ensure tight tolerances (±0.005mm) and flawless surface finishes.

- Material Certifications

- Compliant with ASTM B127, ASME SB-127, and DIN 17750 standards.

- Traceable mill certificates with chemical/physical test reports.

- Customization Expertise

- Slitting, edging, and oscillate winding services for tailored solutions.

- Short lead times on small-batch and prototype orders.

- Global Compliance

- RoHS, REACH, and NACE MR0175 compliance for critical applications.

You ask, we answer

We can provide small monel alloy coil samples for you to check the quality. The sample is free, you only need to pay the shipping cost.

Inconel and Monel alloys have distinct compositions, corrosion resistance properties, temperature ranges of application, mechanical properties, and typical applications. The choice between them depends on the specific requirements of the application, including temperature, corrosion environment, and mechanical properties needed.

Monel 400 alloy is a nickel-copper alloy with excellent corrosion resistance, high strength and toughness, non-toxicity, good heat resistance, and weldability. These properties make it an important material in various industrial fields, including marine engineering, chemical processing, the food industry, and the manufacture of pressure vessels, reactors, and heat exchangers.