Monel Metal Alloy Size and Specifications

Huaxiao Metal Materials Co., Ltd. stands as a leading B2B alloy supplier dedicated to empowering global industries with premium metal solutions. Leveraging decades of expertise, we specialize in delivering high-performance stainless steel, nickel-based alloys, and specialty metals tailored for aerospace, chemical processing, energy, and manufacturing sectors. Our industrial metal solutions combine stringent quality control, advanced processing capabilities, and a robust global supply chain to meet the complex demands of bulk material procurement.

| Alloy Grade | Product Form | Size Range | Remarks |

|---|---|---|---|

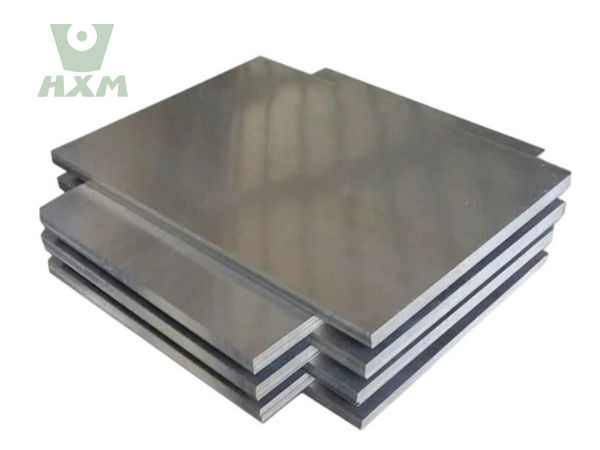

| Monel 400 | Sheet/Plate | Thickness: 2.0–100 mm; Common Sizes: 1m×1m, 1m×2m, 1.22m×2.44m, 1.5m×3m, 1.5m×6m, 1219×C | Complies with ASTM B127; Excellent corrosion resistance and processability |

| Bar/Rod | Diameter: 10–300 mm; Length: 2–6 m | Complies with ASTM B164; Available in black skin or peeled finishes | |

| Pipe/Tube | Various outer diameters and wall thicknesses available to meet different application requirements | Commonly used in marine, chemical, and petroleum industries | |

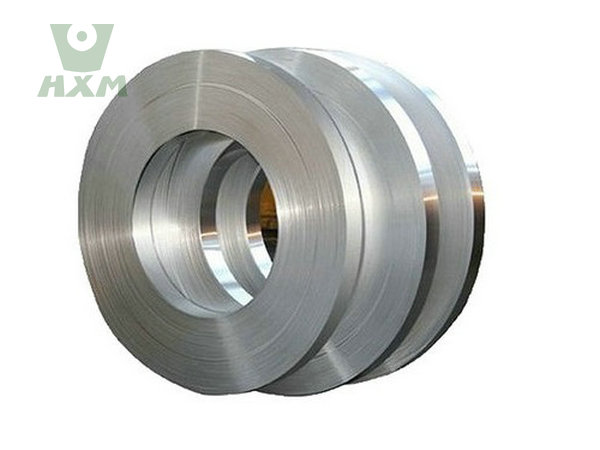

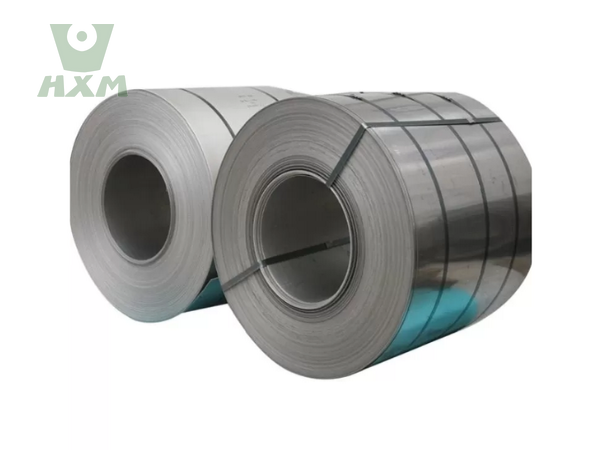

| Strip | Thickness: 0.03–2.0 mm; Width: 20–610 mm | Available in various surface finishes, including bright, 2B, BA, and 8K mirror | |

| Monel K500 | Sheet/Plate | Thickness: 6–80 mm (rolled plate), 12–250 mm (forged plate); Width: 205–710 mm | Complies with ASTM B865; High strength, corrosion resistance, and non-magnetic properties |

| Bar/Rod | Diameter: 10–300 mm; Length: 2–6 m | Available in various finishes, including rough turned, peeled, or cold-drawn | |

| Wire | Diameter: 3.3–9.3 mm; Length: 2 m | Suitable for springs, seals, and other precision components | |

| Pipe/Tube | Various outer diameters and wall thicknesses available to meet different application requirements | Widely used in pumps, valves, and marine equipment due to its high strength and corrosion resistance |

As a leading alloy metal supplier specializing in premium materials for industrial applications, Huaxiao Metal Materials Co., Ltd. is committed to delivering scalable company solutions that drive efficiency and innovation. Whether you’re sourcing corrosion-resistant plates for chemical processing, high-strength alloys for aerospace manufacturing, or bulk materials for sale in the energy sector, our team is ready to align with your procurement needs.

Monel Metal Alloy Standard in Different Countries

Standard/ Specifications for Monel for sale include the following:

| STANDARD | UNS | JIS | BS | GOST | AFNOR | EN |

| Monel 400 | N04400 | NW 4400 | NA 12 | МНЖМц 28-2,5-1,5 | NU 30 | NiCu30Fe |

| Monel K500 | N05500 | – | – | – | – | – |

Supply Shapes:plate, bar, coil, strip, tube, wires, mesh, sheet, pipes, rod.

You can click this button to fill in the basic information of this form. If you have any questions, you can describe them in detail. Our experts will provide you with customized solutions. As a leading metal trading wholesaler in China, we will provide the best metals and services to our customers.

Monel Steel of Chemical Composition

Monel renowned for its high strength and corrosion resistance, boasts a distinct chemical composition. Typically, Monel contains a substantial proportion of nickel, often exceeding 60%, with copper comprising approximately 28% to 34%. Additionally, it incorporates minor elements such as iron, manganese, silicon, carbon, sulfur, aluminum, titanium, and phosphorus, each playing a crucial role in enhancing the alloy’s mechanical properties and corrosion resistance. The precise composition may vary slightly depending on the specific Monel alloy grade and manufacturing process. Huaxiao Metal Supplier has the monel products for sale online.

| Nickel (Ni) | Iron (Fe) | Manganese (Mn) | Silicon (Si) | Carbon (C) | Sulfur (S) | Copper (Cu) | Titanium (Ti) | Aluminum (Al) | |

| Monel 400 | 63% min | 2.5% max | 2.0% max | 0.024% max | 0.3% max | 0.5% max | 28-34% | – | – |

| Monel K500 | 63% min | – | 1.5% max | 0.5% max | 0.25% max | 0.01 max | – | 0.35-0.85 | 2.30-3.15 |

As your trusted supplier, we offer scalable services, from precision cutting to technical consulting, ensuring seamless integration into your manufacturing workflows. With a focus on durability, corrosion resistance, and cost efficiency, we provide certified materials that exceed industry standards while prioritizing transparency and reliability. Partner with us to optimize your supply chain, reduce operational risks, and achieve long-term success in competitive markets.

Monel Steel Mechanical Properties

| Property | Monel 400 (Annealed) | Monel K500 (Aged) | Testing Standard |

|---|---|---|---|

| Tensile Strength | 550-690 MPa | 965-1170 MPa | ASTM E8 |

| Yield Strength (0.2% Offset) | 240-345 MPa | 655-860 MPa | ASTM E8 |

| Elongation (% in 50mm) | 35-45% | 20-25% | ASTM E8 |

| Hardness | 65-85 HRB | 25-35 HRC | ASTM E18 |

| Modulus of Elasticity | 179 GPa | 179 GPa | ASTM E111 |

| Fatigue Strength | 240 MPa (10⁷ cycles) | 380 MPa (10⁷ cycles) | ASTM E466 |

| Impact Toughness (Charpy V) | 100-150 J @ 20°C | 60-80 J @ 20°C | ASTM E23 |

| Density | 8.80 g/cm³ | 8.44 g/cm³ | ASTM B127 |

As a leading certified supplier of premium alloy solutions, we’re committed to delivering tailored company solutions that optimize your supply chain efficiency. To better serve your industry-specific requirements, please complete our brief form below.

What is Monel Alloy?

Monel, also known as Monel metal alloy, is a high-strength, corrosion-resistant alloy material primarily composed of nickel, copper, and other chemical elements. Monel alloy has excellent corrosion resistance, showing outstanding resistance in hydrofluoric acid and fluorine environments, as well as in hot concentrated alkaline. It also resists corrosion by neutral solutions, water, seawater, atmosphere, and organic compounds.

Monel Steel Characteristics

Corrosion Resistance:

- Monel alloy exhibits excellent corrosion resistance in a wide range of environments, including acidic, alkaline, and saline media. It can effectively resist the erosion of various corrosive agents such as sulfuric acid, hydrochloric acid, and chlorides. Huaxiao Metal Supplier provides the high quality monel metal for sale in the world. This makes Monel alloy suitable for use in chemical processing equipment, marine hardware, and other industries where corrosion is a significant concern.

High Temperature Strength:

- Monel alloy maintains good mechanical properties at high temperatures, with a high melting point and antioxidant capacity. It is suitable for manufacturing components that need to operate under high temperature conditions, such as those in aerospace engines, fuel storage tanks, and pipeline systems.

Creep Resistance:

- Under high temperature and high stress conditions, Monel can resist deformation and creep, ensuring its stability and reliability during long-term high-temperature use. Our factory is manufacturing all kinds of product for sale.

Fabrication and Weldability:

- Monel alloy is relatively easy to fabricate and weld, supporting various processing operations such as forging, rolling, drilling, and milling. This allows for the production of complex-shaped parts and components.

Monel Steel Applications

Monel metal alloy is widely applied in various industries due to its excellent corrosion resistance and mechanical properties. Huaxiao Metal Supplier has the monel for sale online. It is commonly used in marine environments, chemical processing, and oil and gas extraction. Additionally, it is suitable for making parts that work in corrosive media such as hydrogen fluoride and sulfuric acid. Huaxiao Metal provides all kinds of monel alloys for various industries. Huaxiao Metal Supplier specializes in Monel for sale and the price is attractive and afforrable.

Customized Package

Huaxiao Metal Manufacturer is comprehensive service for customers. Monel metal alloy packaging typically emphasizes durability and protection to ensure the alloy’s integrity during transportation and storage. The packaging materials are often selected for their ability to resist moisture, dust, and mechanical shock. Additionally, labels providing detailed information about the alloy’s specifications and batch numbers are attached to each package for easy identification and traceability. Welcome to request the price.

FAQ

alloy 400 vs monel 400

Alloy 400 and Monel 400 both refer to a nickel-copper alloy, they have the same chemical composition and properties. This alloy is primarily composed of approximately 63% to 67% nickel and 28% to 34% copper, along small amounts of iron, manganese, silicon, carbon, sulfur, and other elements.

monel metal is a corrosion resistant copper nickel alloy?

Monel metal is a type of corrosion-resistant alloy composed primarily of copper and nickel. This unique composition makes it highly resistant to various corrosive environments. Its excellent corrosion resistance and durability have made it a favored material in numerous industries and applications.

alloy 400 vs Monel k500

Alloy 400 and Monel K-500 are nickel-copper alloys with excellent corrosion resistance. However, Monel K-500 offers higher strength and hardness due to its precipitation hardening mechanism, making it suitable for applications requiring higher mechanical properties. Alloy 400, on the other hand, is more ductile and is widely used in applications where corrosion resistance is the primary concern.

what is monel nickel-copper alloy 400?

Monel nickel-copper alloy 400 is a nickel-copper alloy with excellent corrosion resistance and mechanical properties. It primarily consists of nickel (about 63%) and copper (28-34%), with minor additions of iron, manganese, silicon, and carbon. This alloy is widely used in marine engineering, chemicals, and other industries.