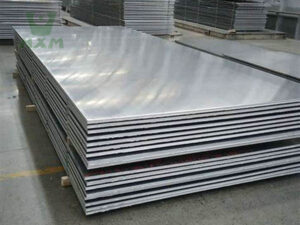

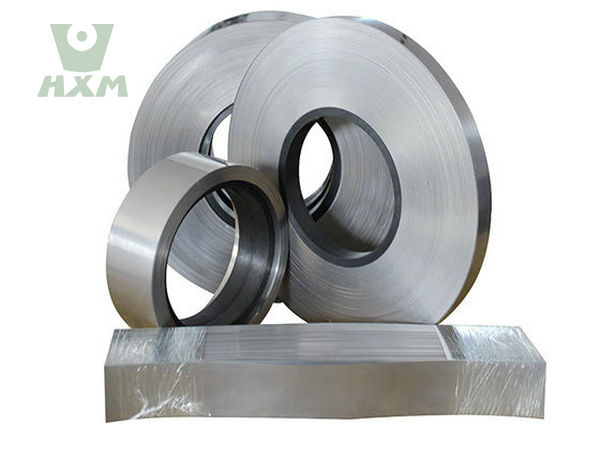

Inconel Alloy Strip, please note that the above table provides a range of standard thicknesses, widths, and lengths for Inconel.

- Dimensions:

- Thickness: 0.05mm – 3mm

- Width: <600mm

- Finish: Bright, Polishing, Mirror, Hairline, Pickled, Peeled, Black

- *Customized size needs to be confirmed with us

- Grades: 600, 601, 601GC, 602CA, 603XL, 617, 625, 625LCF, 686, 690, 693, 706, 718, 718SPF, 725, 740H, X-750,751, MA754, MA758, 783.

Inconel Alloy Strip Size And Specifications

Huaxiao Metal Supplier provides all sizes of inconel alloy strip for sale. Customized specifications are available upon request. Additionally, the exact chemical composition and mechanical properties may vary slightly within the ranges listed, depending on the specific alloy formulation and production process. Custom sizes are also available upon request. Welcome to inquire, and learn about more details about the alloy strip.

Our company has a wide range of inconel alloy strips in various shapes and materials. As a leading alloy supplier in China, we have the most comprehensive alloy products and the highest quality factories. In terms of quality, we have strong after-sales service and quality assurance. If you have a need for alloy reverse, choosing Huaxi is definitely your best choice. Our company is confident in becoming your long-term partner. You can click the button below to contact us quickly, and we will reply to your message as soon as possible.

| Specification | Range/Value |

|---|---|

| Alloy Type | Inconel 600 (UNS N06600, DIN W. Nr. 2.4816) |

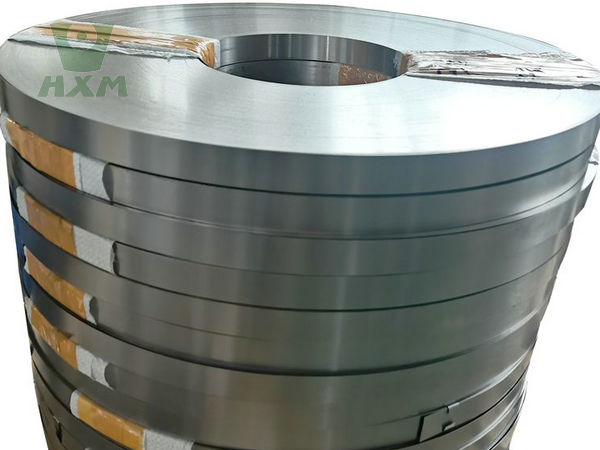

| Shape | Strip |

| Thickness (δ) | 0.05 mm to 5.0 mm (can vary widely) |

| Width | 5.0 mm to 250 mm (common range, can vary) |

| Length | Customizable, typically cut to order |

| Temper/Condition | Annealed, solution-annealed, or as specified by the customer |

| Mechanical Properties (at Room Temperature, Annealed Condition) | – Yield Strength (0.2% Offset): Approximately 318 MPa (46.1 ksi) |

| – Tensile Strength: Approximately 758 MPa (110.0 ksi) | |

| – Elongation: Approximately 56% | |

| – Reduction of Area: Approximately 50% | |

| – Hardness (BHN): Approximately 181 | |

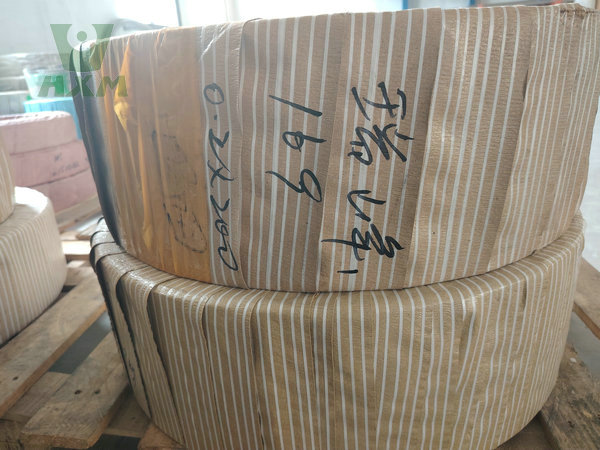

| Packaging | Packed in wooden cases, paper packaging, plastic packing, or foam packaging according to customer requirements |

Huaxiao Metal Manufacturer also provides other shapes of Inconel products, such as bar, coil, sheet&plate, tube&pipe, wire&mesh. The price is affordable and suitable.

Many different shapes of inconel alloys. For your selection. If you need other shapes of alloys, please feel free to contact us. Our company can provide customized services and offer you exclusive alloy solutions. You can click this button to fill in the basic information of this form. If you have any questions, you can describe them in detail. Our experts will provide you with customized solutions. As a leading metal trading wholesaler in China, we will provide the best metals and services to our customers. Welcome to inquire and ask for the lastest price.

What are the Benefits?

Inconel alloy strips are a versatile and high-performance material choice for a wide range of applications, including aerospace, chemical processing, petrochemical, nuclear, and medical industries. Their unique combination of properties makes them an essential component in many high-tech and critical applications. Due to their combination of high temperature resistance, corrosion resistance, and mechanical strength, Inconel alloy strips offer long-term durability and reliability in demanding environments.Welcome to Huaxiao Metal Manufacturer to requset the price, trust you can be satisfied in the alloy products.

Inconel Alloy Strip Applications and Uses

Huaxiao Metal Supplier provides all kinds of inconel steel plate and sheet in the world. Welcome to inquiry.

Marine Applications: Parts and equipment in ships and offshore platforms that need to withstand corrosive seawater and high temperatures, such as pumps, valves, and piping systems.

Electronics Industry:In some applications, Inconel alloy strips are used in electronics due to their non-magnetic properties and resistance to high temperatures.They may be used in components such as connectors, terminals, and heat sinks.

Other Industrial Applications:Inconel alloy strips are also used in marine applications, power generation, and other industries where high temperature resistance, corrosion resistance, and mechanical strength are critical.

You can click this button to fill in the basic information of this form. If you have any questions, you can describe them in detail. Our experts will provide you with customized solutions. As a leading metal trading wholesaler in China, we will provide the best metals and services to our customers.

| Industry | Applications | Key Benefits |

|---|---|---|

| Aerospace | Jet engine parts, exhaust systems | High-temperature strength, oxidation resistance |

| Oil & Gas | Downhole tools, pipelines | Corrosion resistance in harsh environments |

| Chemical | Reactors, heat exchangers | Resists acids and chlorides |

| Power | Gas turbines, nuclear components | Long-term durability at high temps |

| Medical | Surgical tools, implants | Biocompatible and sterilizable |

| Automotive | Turbochargers, exhausts | Handles extreme heat cycles |

| Electronics | Battery contacts, sensors | Reliable conductivity and stability |

Inconel Alloy Strip Advantages

Inconel alloy strips offer unparalleled performance in extreme environments where conventional materials fail. These nickel-chromium superalloys maintain exceptional strength and corrosion resistance at temperatures that would cause most metals to weaken or degrade. Their unique composition provides outstanding resistance to oxidation, carburization, and chloride-induced stress corrosion cracking, making them ideal for demanding applications across aerospace, chemical processing, and energy sectors.

Excellent High-Temperature Resistance:

- Inconel steel strips can maintain good strength and stability at high temperatures.

- They are suitable for applications that require exposure to extreme temperatures, such as aerospace engines, turbine blades, and exhaust systems.

Corrosion Resistance:

- Inconel steel strips exhibit excellent resistance to various types of corrosion, including oxidation, carburization, and stress corrosion cracking.

- They are ideal for use in harsh environments, such as chemical processing plants, marine applications, and nuclear reactors.

You can click this button to fill in the basic information of this form. If you have any questions, you can describe them in detail. Our experts will provide you with customized solutions. As a leading metal trading wholesaler in China, we will provide the best metals and services to our customers.

Good Mechanical Strength:

- Inconel alloy strips have high tensile strength and creep resistance, making them suitable for applications that require high mechanical loads.

- They can maintain their strength and durability even under long-term exposure to high temperatures and mechanical stress.

Ease of Fabrication:

- Inconel steel strips can be easily formed, machined, and welded into various shapes and sizes.

- This versatility makes them suitable for a wide range of manufacturing processes and applications.

Long Service Life:

- Due to their combination of high-temperature resistance, corrosion resistance, and mechanical strength, Inconel alloy strips can offer a long service life in demanding applications.

- This reduces the need for frequent replacements and maintenance, lowering overall costs.

Alloy Factory

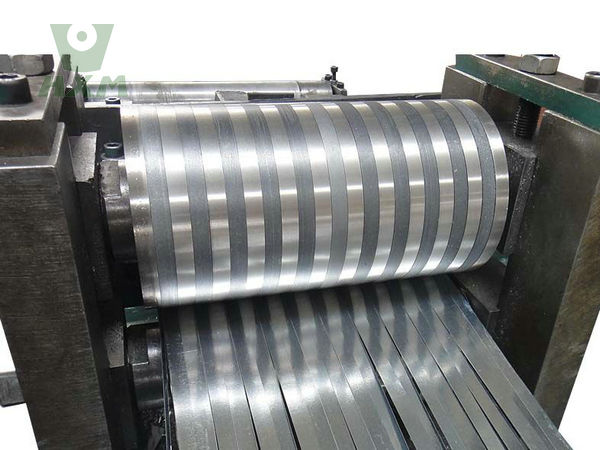

Our Inconel Alloy Strip Factory is a state-of-the-art production hub specializing in the precision manufacturing of high-performance nickel-based alloy strips, primarily for industrial and engineering applications. Located in an advanced metallurgical zone, our facility is fully equipped with cutting-edge cold rolling mills, high-vacuum annealing furnaces, and precision slitting lines, enabling us to meet the stringent requirements of aerospace, petrochemical, marine, power generation, and automotive OEMs.

Huaxiao Metal Supplier provides professional services and reasonable prices, offering customers the best quality products. The Inconel Alloy Strip Alloy Factory is a specialized manufacturing facility dedicated to the production of high-quality Inconel alloy strips. This factory combines advanced technology, rigorous quality control, and experienced personnel to ensure the production of Inconel alloy strips that meet the highest standards.The factory is equipped with state-of-the-art production equipment and machinery, capable of producing Inconel alloy plates with precise dimensions and consistent quality.Welcome to reqiure, and ask to the price.

We maintain full control of the production process from raw material melting to final product testing, ensuring consistency, traceability, and compliance with international standards such as ASTM, AMS, DIN, and ISO 9001/AS9100. Our technical team comprises seasoned metallurgists and application engineers who work closely with clients to provide customized alloy solutions based on operating environment, mechanical performance, and lifecycle cost-efficiency.

With a monthly production capacity exceeding 800 tons, our factory supports large-volume orders, rapid turnaround, and B2B procurement requirements, including mill test reports (MTRs), third-party inspection, and logistics documentation for seamless global shipping.

You ask, we answer

We can provide small inconel alloy sheet samples for you to check the quality. The sample is free, you only need to pay the shipping cost.

They differ in their specific chemical compositions and are tailored for different applications. Inconel is more focused on high-temperature strength and weldability, making it ideal for aerospace and nuclear industries. On the other hand, Hastelloy is optimized for extreme corrosion resistance in harsh environments, making it suitable for chemical processing and other industries where corrosion is a major concern.

Inconel 718 alloy is a versatile nickel-based superalloy that offers a combination of high temperature strength, corrosion resistance, and ease of fabrication. Its wide range of applications in critical industries such as aerospace, gas turbines, nuclear reactors, oil and gas, and automotive demonstrates its importance as a high-performance material.