Inconel Alloy Pipe&Tube, please note that the above table provides a range of standard thicknesses, widths, and lengths for Inconel.

- Dimensions:

- Outside Diameter: Φ3 – Φ600mm

- Wall Thickness: 0.5 – 30mm

- Length ≤ 12000mm

- Shapes: Angle, Hexagon, Square, Channel, Round, etc.

- *Customized size needs to be confirmed with us

- Grades: 600, 601, 601GC, 602CA, 603XL, 617, 625, 625LCF, 686, 690, 693, 706, 718, 718SPF, 725, 740H, X-750,751, MA754, MA758, 783.

Inconel Alloy Pipe Size And Specifications

Huaxiao Metal Supplier provides all sizes of inconel alloy pipe for sale. Customized specifications are available upon request. Additionally, the exact chemical composition and mechanical properties may vary slightly within the ranges listed, depending on the specific alloy formulation and production process. Custom sizes are also available upon request. Welcome to inquire, and learn about more details about the alloy strips.

As a leading alloy supplier in China, we have the most comprehensive alloy products and the highest quality factories. In terms of quality, we have strong after-sales service and quality assurance. If you have a need for alloy reverse, choosing Huaxiao is definitely your best choice. Our company is confident in becoming your long-term partner. You can click the button below to contact us quickly, and we will reply to your message as soon as possible.

| Specification | Inconel 600 | Inconel 625 |

|---|---|---|

| Alloy Type | Inconel 600 | Inconel 625 |

| Pipe Size (DN) | 6 mm (1/4″) to 219 mm (8″) and beyond | 6 mm (1/4″) to 219 mm (8″) and beyond |

| Outer Diameter (OD) | Corresponds to DN size (e.g., DN6 = φ10 mm) | Corresponds to DN size (e.g., DN6 = φ10 mm) |

| Wall Thickness | Sch 10, Sch 40, Sch 80, and others | Sch 10, Sch 40, Sch 80, XXH, and others |

| Length | Standard lengths (e.g., 6 meters) or custom | Standard lengths (e.g., 6 meters) or custom |

| Pressure Rating | Varies with wall thickness and diameter | Varies with wall thickness and diameter |

| Temperature Range | Up to ≈2000 °F (1093 °C) | From cryogenic to ≈2200 °F (1204 °C) |

| Chemical Composition | Ni: min. 72%, Cr: 15.5-17.5%, Fe: balance, etc. | Ni: 58-65%, Cr: 20-23%, Mo: 8-10%, Nb+Ta: 3.15-4.15%, etc. |

| Physical Properties | High corrosion resistance, good mechanical properties at elevated temps., resistance to SCC | Excellent corrosion resistance, high strength at elevated temps., resistance to SCC, pitting |

| Standards | ASTM B163, ASTM B407, ASME SB163, ASME SB407, etc. | ASTM B444, ASTM B829, ASME SB444, ASME SB829, etc. |

Huaxiao Metal Manufacturer also provides other shapes of Inconel products, such as bar, coil, sheet&plate, tube&pipe, wire&mesh. The products are good quality. Welcome to inquire and click the button to get the lastest price quickly.

What are the Benefits?

Inconel alloy strips are a versatile and high-performance material choice for a wide range of applications, including aerospace, chemical processing, petrochemical, nuclear, and medical industries. Their unique combination of properties makes them an essential component in many high-tech and critical applications. Due to their combination of high temperature resistance, corrosion resistance, and mechanical strength, Inconel alloy strips offer long-term durability and reliability in demanding environments.Welcome to Huaxiao Metal Manufacturer to requset the price, trust you can be satisfied in the alloy products.

Inconel Alloy Pipe Applications and Uses

Huaxiao Metal Supplier provides all kinds of inconel alloy plate and sheet in the world. Welcome to inquiry.

- Aerospace: Components that require high temperature stability and corrosion resistance, such as combustion chambers and heat exchangers.

- Chemical Processing: Equipment that handles corrosive materials, such as reactors, tanks, and piping.

- Nuclear Energy: Components in nuclear reactors that need to withstand high radiation and temperature.

You can fill out this form and quickly write down relevant information about you through the button below. We will reply to you within 24 hours and provide you with professional alloy solutions.

Inconel Alloy Pipe Advantages

Exceptional Corrosion Resistance:

- Inconel alloy pipes are highly resistant to corrosion in various environments, including those with high temperatures and pressures.

- The unique composition of Inconel alloys, with elements like nickel, chromium, and molybdenum, contributes to their corrosion resistance.

High-Temperature Stability:

- Inconel alloy pipes maintain their mechanical properties at elevated temperatures.

- They are ideal for applications in industries such as aerospace and oil & gas, where high-temperature stability is crucial.

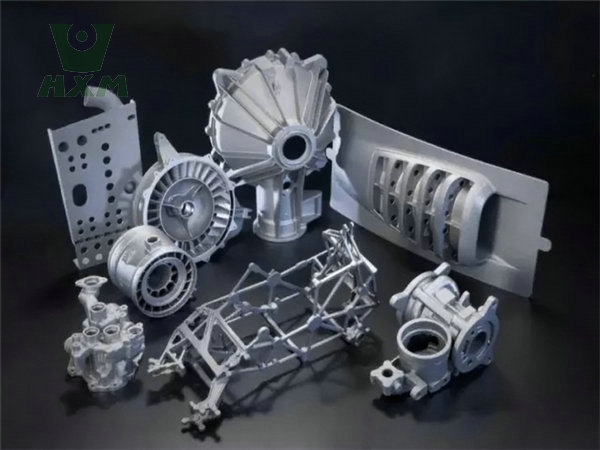

Many different shapes of inconel alloys. For your selection. If you need other shapes of alloys, please feel free to contact us. Our company can provide customized services and offer you exclusive alloy solutions. You can click this button to fill in the basic information of this form. If you have any questions, you can describe them in detail. Our experts will provide you with customized solutions. As a leading metal trading wholesaler in China, we will provide the best metals and services to our customers. Welcome to inquire and ask for the lastest price.

Good Oxidation Resistance:

- At high temperatures, Inconel alloy pipes form a dense oxide film on their surface, which prevents further oxidation.

- This characteristic extends the service life of the pipes and makes them suitable for applications with high-temperature exposure.

Ease of Welding and Fabrication:

- Inconel alloy pipes are easy to weld using various methods without experiencing post-weld cracking.

- They can be machined and formed into complex shapes and sizes, making them versatile for a wide range of applications.

Cost-Effectiveness:

- Although Inconel alloy pipes may have a higher initial cost compared to some other materials, their long service life reduces the need for frequent replacements and maintenance.

- This makes them cost-effective in the long run, particularly in demanding applications where reliability and durability are paramount.

Alloy Factory

Huaxiao Metal Supplier provides professional services and reasonable prices, offering customers the best quality products. The Inconel Alloy Strip Alloy Factory is a specialized manufacturing facility dedicated to the production of high-quality Inconel alloy strips. This factory combines advanced technology, rigorous quality control, and experienced personnel to ensure the production of Inconel alloy strips that meet the highest standards.The factory is equipped with state-of-the-art production equipment and machinery, capable of producing Inconel alloy plates with precise dimensions and consistent quality.Welcome to reqiure, and ask to the price.

Quality Assurance & Certifications

Every batch of Inconel alloy is fully traceable and accompanied by MIL-SPEC compliance documentation, including:

- AMS 5540 (Inconel 600), AMS 5666 (Inconel 625), and AMS 5596 (Inconel 718) certifications.

- NADCAP-accredited chemical analysis and mechanical testing reports.

- ASME Section IX welding procedure qualifications for fabricated components.

Our factory adheres to ISO 9001:2015 and ISO 14001 standards, ensuring consistency in material performance while minimizing environmental impact.

You ask, we answer

We can provide small inconel alloy sheet samples for you to check the quality. The sample is free, you only need to pay the shipping cost.

They differ in their specific chemical compositions and are tailored for different applications. Inconel is more focused on high-temperature strength and weldability, making it ideal for aerospace and nuclear industries. On the other hand, Hastelloy is optimized for extreme corrosion resistance in harsh environments, making it suitable for chemical processing and other industries where corrosion is a major concern.

Inconel 718 alloy is a versatile nickel-based superalloy that offers a combination of high temperature strength, corrosion resistance, and ease of fabrication. Its wide range of applications in critical industries such as aerospace, gas turbines, nuclear reactors, oil and gas, and automotive demonstrates its importance as a high-performance material.