Inconel Alloy Coil, please note that the above table provides a range of standard thicknesses, widths, and lengths for Inconel.

- Dimensions:

- Thickness: 0.5mm – 50mm

- Width: >600mm

- Finish: Bright, Polishing, Mirror, Hairline, Pickled, Peeled, Black

- *Customized size needs to be confirmed with us

- Grades: 600, 601, 601GC, 602CA, 603XL, 617, 625, 625LCF, 686, 690, 693, 706, 718, 718SPF, 725, 740H, X-750,751, MA754, MA758, 783.

Inconel Alloy Coil Size And Specifications

Huaxiao Metal Supplier provides all sizes of inconel alloy coil for sale. Customized specifications are available upon request. Additionally, the exact chemical composition and mechanical properties may vary slightly within the ranges listed, depending on the specific alloy formulation and production process. Custom sizes are also available upon request. Welcome to inquire, and learn about more details about the alloy coil.

| Parameter | Range | Tolerance | Notes |

|---|---|---|---|

| Thickness (mm) | 0.1 – 6.0 | ±0.02mm (cold-rolled) ±0.05mm (hot-rolled) | Precision strips (0.1–1.0mm) for aerospace |

| Width (mm) | 50 – 1500 | ±1mm (≤300mm) ±2mm (>300mm) | Custom slitting available |

| Length (m) | 10 – 500 (continuous) | ±0.5% of total length | Longer coils for piping/structural use |

| Coil Weight (kg) | 500 – 10,000 | ±2% of ordered weight | Standard mill sizes: 2–5 tons |

| Inner Diameter (ID) | 508mm (20″) or 610mm (24″) | ±5mm | Compatible with standard uncoilers |

You can click this button to fill in the basic information of this form. If you have any questions, you can describe them in detail. Our experts will provide you with customized solutions. As a leading metal trading wholesaler in China, we will provide the best metals and services to our customers.

Inconel Alloy Coil Different Materials

Huaxiao Metal has many different materials of Inconel metal alloys, and the table below shows the materials we have. If you need alloys of other materials, please feel free to contact us, and our experts will provide you with professional solutions. We have a large inventory of inconel alloys and provide cutting, customization, and other services. Welcome to call for consultation and quotation.

| Model | Coil Size (Diameter x Thickness) | Specifications |

|---|---|---|

| Inconel 600 | Various sizes available upon request | High nickel and chromium content, excellent corrosion and oxidation resistance at high temperatures, suitable for applications up to 2000°F (1093°C) |

| Inconel 601 | Various sizes available upon request | Designed for extreme environments, excellent high-temperature oxidation resistance, superior corrosion resistance, and good mechanical properties |

| Inconel 625 | Various sizes available upon request | High corrosion resistance in various severe environments, resistant to inorganic acids and alkalis, easily welded and processed through standard shop practices |

| Inconel 718 | Various sizes available upon request | High strength, corrosion-resistant nickel-chromium alloy, initially developed for the aerospace industry, widely used in oil, aerospace, and power generation industries |

| Inconel 686/Alloy 686 | Various sizes available upon request | Improved chromium content and reduced iron compared to C276 alloy, high resistance to both reducing and oxidizing media, high thermal stability of the structure, and improved intergranular corrosion resistance |

What are the Benefits?

Inconel alloy coils exhibit exceptional corrosion resistance, making them suitable for use in harsh environments where other materials may fail. This resistance to corrosion is due to their high nickel and chromium content, which forms a protective oxide layer on the surface of the alloy.Inconel alloy coils possess outstanding high-temperature strength and stability. They can maintain their mechanical properties and structural integrity at temperatures up to 2000°F (1093°C), making them ideal for applications in extreme thermal conditions.Welcome to Huaxiao Metal Manufacturer to requset the price, trust you can be satisfied in the alloy products.

Inconel Alloy Coil Applications and Uses

Huaxiao Metal Supplier provides all kinds of inconel alloy coil in the world. Welcome to inquiry.

- Aerospace Industry: Inconel alloy coils are widely used in the aerospace industry for manufacturing components such as jet engine parts, turbine blades, and combustion chambers. Their high-temperature strength, corrosion resistance, and creep resistance make them ideal for these demanding applications.

- Chemical Processing: Inconel alloy coils are also used in the chemical processing industry for equipment and piping that handles corrosive chemicals. Their corrosion resistance ensures that they can withstand the harsh environments found in chemical plants.

- Petroleum and Natural Gas: Inconel alloy coils are used in the petroleum and natural gas industry for components that are exposed to high temperatures and pressures, such as valves, pumps, and piping. Their high-temperature strength and creep resistance make them suitable for these applications.

- Power Generation: Inconel alloy coils are used in power generation equipment, including turbines and generators, due to their ability to withstand high temperatures and pressures.

You can click this button to fill in the basic information of this form. If you have any questions, you can describe them in detail. Our experts will provide you with customized solutions. As a leading metal trading wholesaler in China, we will provide the best metals and services to our customers.

Inconel Alloy Coil Advantages

Inconel alloy coil, a high-performance nickel-chromium-based superalloy, stands out for its exceptional properties across diverse industrial applications. Its most prominent advantage lies in its remarkable corrosion resistance, enabling it to withstand exposure to harsh chemicals, acids, alkalis, and even seawater without degradation. This characteristic makes it indispensable in marine, chemical processing, and offshore oil and gas sectors. Additionally, Inconel alloy coil exhibits outstanding high-temperature strength and stability, retaining its mechanical integrity at elevated temperatures, which is crucial for aerospace, gas turbine, and heat-treating equipment applications. Its superior oxidation resistance further enhances its durability by preventing surface deterioration. Moreover, the alloy’s weldability and formability allow for the fabrication of complex components with ease.

- Exceptional Corrosion Resistance: Inconel alloy coils are highly resistant to corrosion, making them ideal for use in harsh environments where exposure to corrosive substances is common. This corrosion resistance is due to their high nickel and chromium content, which forms a protective oxide layer on the surface of the alloy.

- Outstanding High-Temperature Strength: Inconel alloy coils maintain their mechanical properties and structural integrity at high temperatures, up to 2000°F (1093°C). This makes them suitable for applications where components are exposed to extreme thermal conditions.

You can click this button to fill in the basic information of this form. If you have any questions, you can describe them in detail. Our experts will provide you with customized solutions. As a leading metal trading wholesaler in China, we will provide the best metals and services to our customers.

- Creep Resistance: Inconel alloy coils are highly resistant to creep, which is the gradual deformation of a material under sustained load and high temperatures. This property ensures that components made from Inconel alloy coils maintain their shape and size over time, even in demanding conditions.

- Good Fabrication Characteristics: Inconel alloy coils can be easily welded, formed, and machined into various shapes and sizes. This versatility allows for a wide range of applications and makes Inconel alloy coils an excellent choice for custom fabrication projects.

- Long-Term Durability: Due to their corrosion resistance, high-temperature strength, and creep resistance, Inconel alloy coils offer long-term durability and reliability. They can withstand the rigors of harsh environments and demanding applications, reducing the need for frequent replacements or repairs.

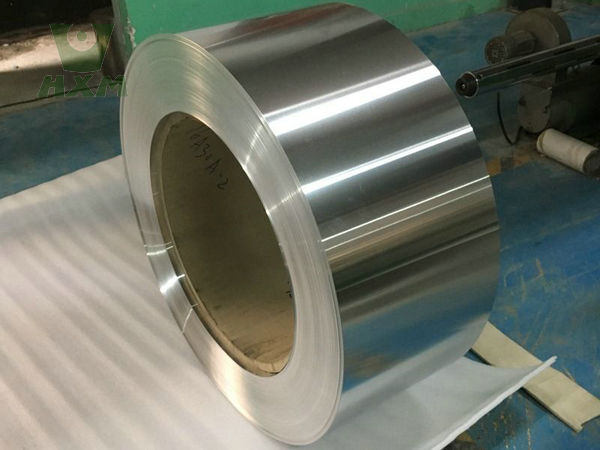

Alloy Factory

Huaxiao Metal Supplier provides professional services and reasonable prices, offering customers the best quality products. The Inconel Alloy Coil Alloy Factory is a specialized manufacturing facility dedicated to the production of high-quality Inconel alloy coils. This factory combines advanced technology, rigorous quality control, and experienced personnel to ensure the production of Inconel alloy coils that meet the highest standards.The factory is equipped with state-of-the-art production equipment and machinery, capable of producing Inconel alloy coils with precise dimensions and consistent quality.Welcome to reqiure, and ask to the price.

We offer volume discounts and flexible pricing options to accommodate various purchasing requirements. Our dedicated sales team is always available to assist you with product inquiries, customization requests, and order processing to ensure a seamless purchasing experience. Huaxiao Metal Supplier provides professional services and reasonable prices, offering customers the best quality products. Welcome to reqiure, and ask to the price. You can click the button and get the quote quickly.

You ask, we answer

We can provide small inconel alloy sheet samples for you to check the quality. The sample is free, you only need to pay the shipping cost.

They differ in their specific chemical compositions and are tailored for different applications. Inconel is more focused on high-temperature strength and weldability, making it ideal for aerospace and nuclear industries. On the other hand, Hastelloy is optimized for extreme corrosion resistance in harsh environments, making it suitable for chemical processing and other industries where corrosion is a major concern.

Inconel 718 alloy is a versatile nickel-based superalloy that offers a combination of high temperature strength, corrosion resistance, and ease of fabrication. Its wide range of applications in critical industries such as aerospace, gas turbines, nuclear reactors, oil and gas, and automotive demonstrates its importance as a high-performance material.