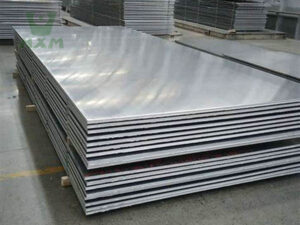

Inconel Alloy Bar, please note that the above table provides a range of standard thicknesses, widths, and lengths for Inconel.

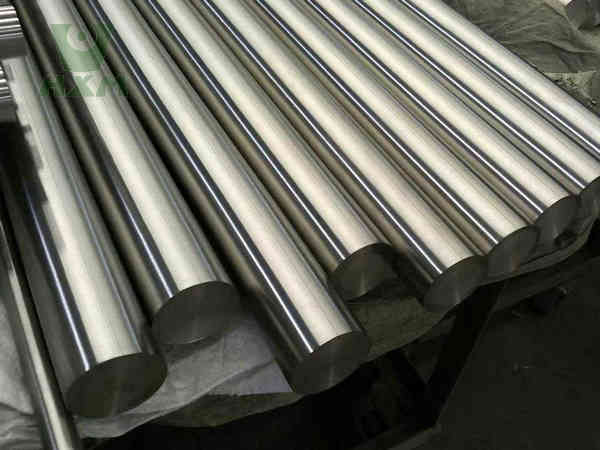

- Dimensions:

- Outside Diameter: Φ5 – Φ500mm

- Length: 100 mm To 3000 mm

- Shapes: Angle, Hexagon, Square, Channel, Round, Flat etc.

- Finish: Bright, Polishing, Mirror, Hairline, Pickled, Peeled, Black

- *Customized size needs to be confirmed with us

- Grades: 600, 601, 601GC, 602CA, 603XL, 617, 625, 625LCF, 686, 690, 693, 706, 718, 718SPF, 725, 740H, X-750,751, MA754, MA758, 783.

Inconel Alloy Bar Size And Specifications

Huaxiao Metal Supplier provides all sizes of inconel alloy bar for sale. Customized specifications are available upon request. Additionally, the exact chemical composition and mechanical properties may vary slightly within the ranges listed, depending on the specific alloy formulation and production process. Custom sizes are also available upon request. Welcome to inquire, and learn about more details about the alloy plate.

As a leading alloy supplier in China, we have the most comprehensive alloy products and the highest quality factories. In terms of quality, we have strong after-sales service and quality assurance. If you have a need for alloy reverse, choosing Huaxiao is definitely your best choice. Our company is confident in becoming your long-term partner. You can click the button below to contact us quickly, and we will reply to your message as soon as possible.

| Specification | Range/Value |

|---|---|

| Alloy Type | Inconel (various grades such as Inconel 600, 601, 625, 718, etc.) |

| Shape | Round, Square, Hexagonal, Rectangular, etc. |

| Diameter (Round Bar) | 5 mm to 500 mm (or 0.197 in to 19.685 in) |

| Size (Square, Hex, Rectangular Bar) | Parallel surface distance/thickness/width as per requirements |

| Length | 100 mm to 3000 mm (or 3.937 in to 118.11 in) and above |

| Finish | Black, Bright Polished, Rough Turned, NO.4 Finish, Matt Finish, BA Finish |

| Tolerance | H8, H9, H10, H11, H12, H13, K9, K10, K11, K12, or as per client requirements |

| Standard | ASTM, DIN, EN, UNS, etc. |

| Certification | AISI, ASTM, etc. |

| Surface Treatment | Cold-drawing, Polishing, etc. |

| Packaging | Wooden Box, Paper Packaging, Plastic Packing, Foam Packaging, or as per customer requirements |

Huaxiao Metal Manufacturer also provides other shapes of Inconel products, such as sheet &plate , coil, strip, tube&pipe, wire&mesh. The price is affordable and suitable. The products has the good quality and assurance.

What are the Benefits?

Inconel alloy bars offer numerous benefits, including high temperature resistance, corrosion resistance, good mechanical properties, versatile fabrication options, and long service life. They are suitable for a wide range of applications, such as aerospace, chemical processing, and oil and gas industries, ensuring reliability and performance, making them an ideal choice for a wide range of demanding applications. Inconel alloy bars are versatile and essential in various industries due to their high temperature resistance, corrosion resistance, and mechanical strength.Welcome to Huaxiao Metal Manufacturer to requset the price, trust you can be satisfied in the alloy products.

Inconel Alloy Bar Applications and Uses

Huaxiao Metal Supplier provides all kinds of inconel alloy bar in the world. Welcome to inquiry and ask the price.

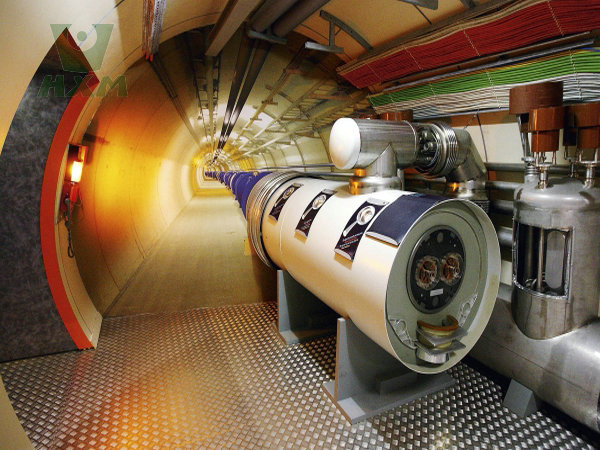

Aerospace Industry: Components exposed to high temperatures and corrosive environments, such as turbine blades, combustion chambers, and exhaust systems.

Chemical Processing: Equipment and parts that require resistance to harsh chemicals and high temperatures, such as reactors, heat exchangers, and valves.

Oil and Gas Industry: Downhole tools and equipment, including drill bits, casing, and tubing, due to their resistance to high pressures, temperatures, and corrosive environments.

Inconel Alloy Bar Advantages

1. High Temperature Resistance

- Excellent Strength at Elevated Temperatures: Inconel alloy bars maintain high mechanical strength and stability even at extremely high temperatures, making them ideal for applications where thermal stress is a concern.

- Oxidation and Carburization Resistance: They exhibit exceptional resistance to oxidation and carburization, ensuring longer service life in oxidizing and carburizing environments.

2. Corrosion Resistance

- Resistance to Various Corrosive Media: Inconel alloy bars are highly resistant to a wide range of corrosive media, including acids, bases, and other aggressive chemicals. This makes them suitable for use in harsh chemical processing environments.

- Chloride Stress Corrosion Cracking Resistance (for certain grades): Some grades of Inconel alloy, such as Inconel 600, offer resistance to chloride stress corrosion cracking, which is crucial in applications involving chloride-containing environments.

3. Mechanical Properties

- Good Formability: Inconel alloy bars can be easily formed into various shapes and sizes, allowing for versatility in design and fabrication.

- High Creep Strength: They possess high creep strength, which is essential for applications involving sustained loads and elevated temperatures.

Many different shapes of inconel alloys. For your selection. If you need other shapes of alloys, please feel free to contact us. Our company can provide customized services and offer you exclusive alloy solutions. You can click this button to fill in the basic information of this form. If you have any questions, you can describe them in detail. Our experts will provide you with customized solutions. As a leading metal trading wholesaler in China, we will provide the best metals and services to our customers. Welcome to inquire and ask for the lastest price.

4. Fabrication and Weldability

- Reasonable Weldability: Inconel alloy bars can be welded using various welding techniques, providing flexibility in manufacturing processes. However, proper welding practices and controls are necessary to avoid welding defects such as hot cracking.

- Machinability: Although Inconel alloys are generally harder to machine than steels, they can be machined with appropriate tooling and cutting parameters.

5. Versatile Applications

- Wide Range of Applications: Due to their combination of high temperature resistance, corrosion resistance, and good mechanical properties, Inconel alloy bars are used in a wide range of applications, including aerospace, chemical processing, power generation, and oil and gas industries.

6. Longevity and Reliability

- Extended Service Life: The resistance to high temperatures, corrosion, and creep deformation contributes to the extended service life of components made from Inconel alloy bars.

- Consistent Performance: Inconel alloys are known for their consistent performance over time, ensuring reliability in critical applications.

Alloy Factory

Huaxiao Metal Supplier provides professional services and reasonable prices, offering customers the best quality products. The Inconel Alloy Factory is a specialized manufacturing facility dedicated to the production of high-quality Inconel alloy. Alloy Factory bar can be described as a product manufactured in an alloy factory, specifically referring to an alloy bar. Alloy bars are widely used in various industries due to their excellent mechanical properties, corrosion resistance, and heat resistance. Welcome to reqiure, and ask to the price.

Our vertically integrated facility combines cutting-edge vacuum induction melting (VIM) and electroslag remelting (ESR) technologies to ensure ultra-pure alloy compositions with minimal impurities. The production workflow includes:

- Primary Melting & Refining: Precision control of nickel, chromium, molybdenum, and niobium ratios in inert atmospheres to eliminate oxidation.

- Hot & Cold Working: State-of-the-art forging presses, rolling mills, and extrusion lines for producing billets, bars, sheets, tubes, and wire forms with tight dimensional tolerances (±0.002”).

- Heat Treatment: Computer-controlled solution annealing, precipitation hardening, and stress-relieving processes to optimize grain structure and mechanical properties.

- Non-Destructive Testing (NDT): In-line ultrasonic testing (UT), eddy current inspection, and liquid penetrant testing to guarantee defect-free materials.

You ask, we answer

We can provide small inconel alloy sheet samples for you to check the quality. The sample is free, you only need to pay the shipping cost.

They differ in their specific chemical compositions and are tailored for different applications. Inconel is more focused on high-temperature strength and weldability, making it ideal for aerospace and nuclear industries. On the other hand, Hastelloy is optimized for extreme corrosion resistance in harsh environments, making it suitable for chemical processing and other industries where corrosion is a major concern.

Inconel 718 alloy is a versatile nickel-based superalloy that offers a combination of high temperature strength, corrosion resistance, and ease of fabrication. Its wide range of applications in critical industries such as aerospace, gas turbines, nuclear reactors, oil and gas, and automotive demonstrates its importance as a high-performance material.