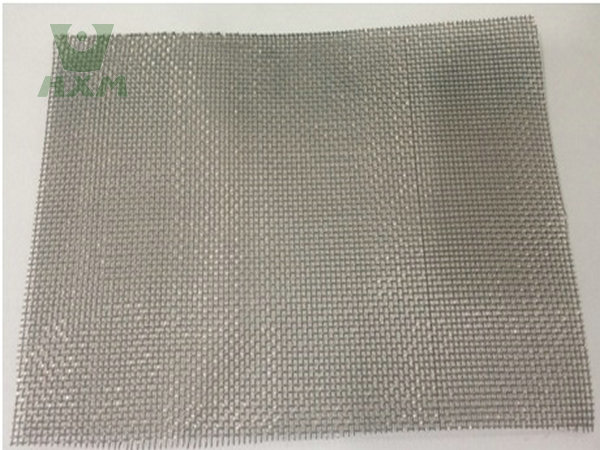

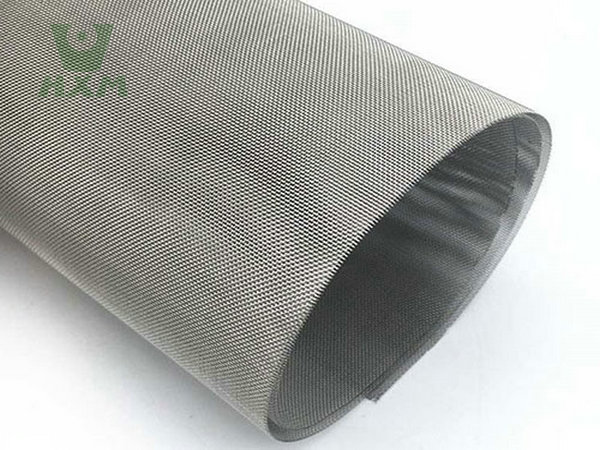

Incoloy Alloy Wire&Mesh, please note that the above table provides a range of standard thicknesses, widths, and lengths for Incoloy.

- Dimensions:

Opening Size: 0.05mm to 30mm

Wire Diameter: 0.05mm to 8.0mm

Wire Lengths: up to 3000mm

- *Customized size needs to be confirmed with us

- Grades: 800, 800H, 800HT, 803, 825, 832, 864, 890, 903, 907, 908, 909,925, 926, 945, 945X, MA956, A-286, 020, 028,DS, 330, 25-6HN, 27-7MO, X-750.

Incoloy Alloy Wire Size And Specifications

Huaxiao Metal Supplier provides all sizes of incoloy alloy wire and mesh for sale. Customized specifications are available upon request. Additionally, the exact chemical composition and mechanical properties may vary slightly within the ranges listed, depending on the specific alloy formulation and production process. Custom sizes are also available upon request. Welcome to inquire, and learn about more details about the alloy wires.

| Alloy Type | Wire Diameter Range (mm) | Chemical Composition (%) | Density (g/cm³) | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation at Break (%) | Melting Point (°C) |

|---|---|---|---|---|---|---|---|

| Incoloy 800 | 0.1 – 10.0 | Ni: 30-35, Cr: 19-23, Fe: Balance, C: ≤0.10, Mn: ≤1.50, Si: ≤1.00, Cu: ≤0.75, Al: ≤0.45, Ti: ≤0.45, S: ≤0.015, P: ≤0.030 | 8.0 | 415-550 | 170-310 | ≥30 | 1350-1400 |

| Incoloy 825 | 0.05 – 8.0 | Ni: 38-46, Cr: 19.5-23.5, Fe: Balance, C: ≤0.03, Mn: ≤1.00, Si: ≤0.50, Cu: 1.5-3.0, Mo: 2.5-3.5, Al: ≤0.20, Ti: 0.60-1.20, S: ≤0.010, P: ≤0.020 | 8.14 | 485-620 | 205-415 | ≥35 | 1370-1400 |

| Incoloy 925 | 0.1 – 6.0 | Ni: 42-48, Cr: 20-23, Fe: Balance (min. 18), Mo: 2.5-3.5, Cu: 1.5-3.0, Mn: ≤1.00, Si: ≤0.50, C: ≤0.02, S: ≤0.010, P: ≤0.020, Al: ≤0.40, Ti: ≤0.40 | 8.08 | 620-825 | 345-550 | ≥25 | 1310-1370 |

Huaxiao Metal Manufacturer also provides other shapes of Incoloy products, such as coil,plate&sheet,strip, tube&pipe, bar. The price is affordable and suitable. Welcome to inqiure and learn more details about incoloy.

Our experts will provide you with customized solutions. As a leading metal trading wholesaler in China, we will provide the best metals and services to our customers. Our company has many products with guaranteed quality, and of course, we can also provide customized services to offer you exclusive products. You can click this button to fill in the basic information of this form. If you have any questions, you can describe them in detail.

What are the Benefits?

Huaxiao Metal Manufacturer offers customizable options for Incoloy alloy wires, including different thicknesses, widths, lengths, and surface finishes.This allows customers to tailor the material to their specific needs and applications. Incoloy alloy wire mesh combines corrosion resistance, high-temperature strength, oxidation resistance, good mechanical properties, versatility in applications, customizability, and longevity to provide a robust and reliable solution for various demanding environments and applications. Welcome to Huaxiao Metal Manufacturer to request the price, trust you can be satisfied in the alloy products.

Incoloy Alloy Wire Applications and Uses

Incoloy alloy wires, known for their exceptional corrosion resistance, high-temperature strength, and oxidation resistance, are widely used in demanding industrial environments. As a leading supplier of high-quality Incoloy wires, we provide precise diameters, custom tempers, and certified materials to meet stringent industry standards. Whether for corrosive environments or ultra-high-temperature applications, Incoloy alloy wires deliver unmatched reliability.

Huaxiao Metal Supplier provides all kinds of incoloy alloy pipes in the world. Welcome to inquiry.

Aerospace Industry

- Exhaust Systems and Combustion Chambers: Incoloy alloy wire is used in the construction of exhaust systems and combustion chambers in aerospace applications, where it withstands the high temperatures and corrosive environments of jet engines.

- Structural Components: The alloy is also used in other structural components that require high strength and corrosion resistance at elevated temperatures.

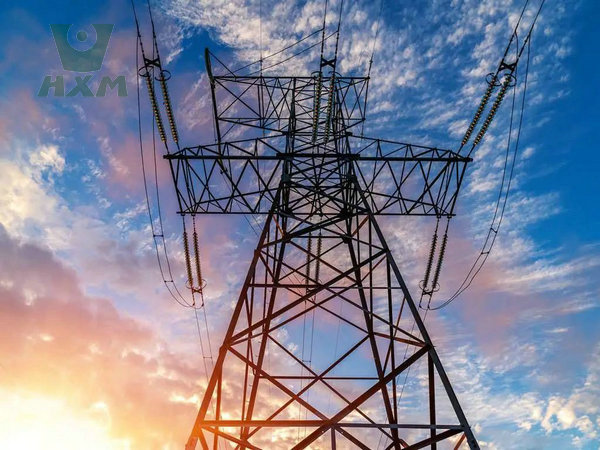

Power Generation Industry

- Turbine Components: Incoloy alloy wire is used in the manufacture of turbine blades and other components in power generation turbines, where it resists the high temperatures and corrosive environments of combustion processes.

- Electrical Heating Elements: The alloy is also used in electrical heating elements, such as those found in boilers and furnaces, due to its resistance to oxidation and high-temperature corrosion.

Environmental Systems

- Incinerators and Thermal Oxidizers: Incoloy alloy wire mesh is used in incinerators and thermal oxidizers for waste treatment, where it withstands the high temperatures and corrosive environments of combustion processes.

- Emissions Control Equipment: The alloy is also used in emissions control equipment, such as scrubbers and catalysts, to reduce pollutants in industrial exhaust streams.

Incoloy Alloy Wire of Advantages

Incoloy alloy wire offers exceptional performance in highly corrosive and high-temperature environments, making it an ideal choice for demanding industrial applications. Known for its excellent resistance to oxidation, carburization, and sulfur-containing atmospheres, Incoloy wire maintains its mechanical strength and structural integrity under extreme conditions. This nickel-iron-chromium alloy is especially suited for use in marine, chemical processing, power generation, and heat-treatment industries. It exhibits outstanding resistance to pitting, crevice corrosion, and stress corrosion cracking—even in aggressive acidic or saline environments.

Longevity and Durability:

- The corrosion resistance, high-temperature strength, and good mechanical properties of Incoloy alloy wire mesh contribute to its long service life and durability.

- This makes it a cost-effective choice for applications where reliability and long-term performance are critical.

Corrosion Resistance:

- Incoloy alloys are known for their excellent corrosion resistance, which makes them suitable for use in environments where exposure to corrosive chemicals or high-temperature corrosive gases is a concern.

- The nickel and chromium content in Incoloy alloys provides a protective oxide layer that resists attack from many corrosive agents.

High Temperature Strength:

- Incoloy alloys maintain their strength and ductility at high temperatures, making them ideal for applications where elevated temperatures are a factor.

- This high-temperature strength ensures that the wire mesh retains its structural integrity and performance even in demanding thermal environments.

Oxidation Resistance:

- Incoloy alloys are resistant to oxidation at high temperatures, which helps to prevent degradation and maintain the integrity of the wire mesh over time.

Good Mechanical Properties:

- Incoloy alloy wire mesh has good tensile strength, yield strength, and ductility, which allows it to withstand mechanical stress and deformation.

- These mechanical properties make it suitable for applications that require strength and durability.

Customizable Options:

- Incoloy alloy wire mesh can be manufactured in various wire diameters, mesh sizes, and weave patterns to meet specific application requirements.

- This customizability allows for tailored solutions that optimize performance and cost-effectiveness.

Our company has many products with guaranteed quality, and of course, we can also provide customized services to offer you exclusive products. You can click this button to fill in the basic information of this form. If you have any questions, you can describe them in detail. You can click this button to fill in the basic information of this form. If you have any questions, you can describe them in detail. Our experts will provide you with customized solutions. As a leading metal trading wholesaler in China, we will provide the best metals and services to our customers. Our experts will provide you with customized solutions.

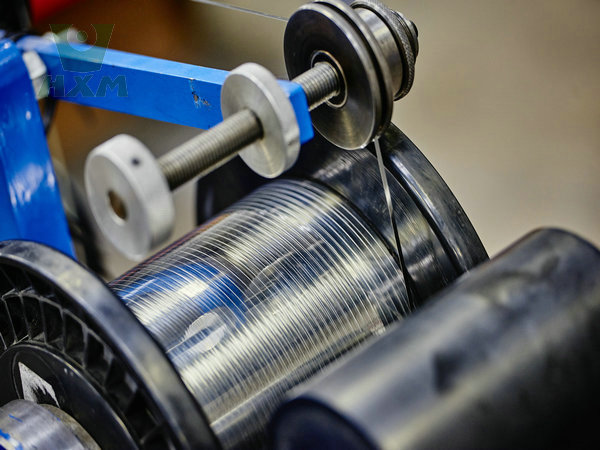

Alloy Factory

Huaxiao Metal Supplier provides professional services and reasonable prices, offering customers the best quality products. The Incoloy Alloy Wire Alloy Factory is a specialized manufacturing facility dedicated to the production of high-quality Incoloy alloy wires. This factory combines advanced technology, rigorous quality control, and experienced personnel to ensure the production of Incoloy alloy wires that meet the highest standards.The factory is equipped with state-of-the-art production equipment and machinery, capable of producing Incoloy alloy wire with precise dimensions and consistent quality.Welcome to reqiure, and ask to the price.

Our company has many products with guaranteed quality, and of course, we can also provide customized services to offer you exclusive products. You can click this button to fill in the basic information of this form. If you have any questions, you can describe them in detail. You can click this button to fill in the basic information of this form. If you have any questions, you can describe them in detail. Our experts will provide you with customized solutions. As a leading metal trading wholesaler in China, we will provide the best metals and services to our customers. Our experts will provide you with customized solutions.

Why Choose Huaxiao Metal for Incoloy Wire Mesh?

- Material Authenticity: 100% traceable alloy sourced from certified mills (e.g., Outokumpu, Special Metals).

- Precision Engineering: Laser-cut edges, tight tolerances (±0.01mm), and custom weaves.

- Testing & Compliance:

- PMI (Positive Material Identification) testing.

- Corrosion resistance reports per ASTM G28 and G48.

- Global Reach: 24/7 support with warehouses in North America, Europe, and Asia.

Welcome to consult about metal related issues. If you have any metal related needs, please feel free to contact us. I will provide you with the highest quality solutions and products. I hope we can establish a long-term cooperation and stable trade relationship. As a leading metal supplier in China, we will provide you with the most suitable and high-quality prices. Click the button above to contact us now.

You ask, we answer

We can provide small incoloy alloy plate&sheet samples for you to check the quality. The sample is free, you only need to pay the shipping cost.

Incoloy and Hastelloy are both nickel-based alloys with high corrosion resistance and mechanical strength. However, they differ in their chemical composition, properties, and applications. Incoloy is more cost-effective due to its higher iron content and is suitable for high-temperature applications, while Hastelloy offers superior corrosion resistance in severe environments and is primarily used in chemical processing and petrochemical industries.

Incoloy 800 alloy is a versatile nickel-iron-chromium alloy with a wide range of applications due to its high-temperature strength, corrosion resistance, and fabricability. Its unique chemical composition and properties make it an ideal material for demanding applications in various industries.