Incoloy Alloy Coil please note that the above table provides a range of standard thicknesses, widths, and lengths for Incoloy.

- Dimensions:

- Thickness: 0.3-200mm

- Width: >600mm

- *Customized size needs to be confirmed with us

- Grades: 800, 800H, 800HT, 803, 825, 832, 864, 890, 903, 907, 908, 909, 925, 926, 945, 945X, MA956, A-286, 020, 028,DS, 330, 25-6HN, 27-7MO.

Incoloy Alloy Coil Size And Specifications

Huaxiao Metal Supplier provides all sizes of incoloy alloy coil for sale. Customized specifications are available upon request. Additionally, the exact chemical composition and mechanical properties may vary slightly within the ranges listed, depending on the specific alloy formulation and production process. Custom sizes are also available upon request. Welcome to inquire, and learn about more details about the alloy coils.

| Specification/Size | Description/Range |

|---|---|

| Alloy | Incoloy 20 (Alloy 20, UNS N08020) |

| Thickness (mm) | 0.1 – 10.0 (can vary widely) |

| Width (mm) | 10 – 2000 (customizable based on needs) |

| Length (m) | 2 – 6 (coils, can be cut to specific lengths) |

| Density (g/cm³) | 8.08 |

| Melting Point (°C) | 1357 – 1430 |

| Chemical Composition | – Cr: 19.0 – 21.0%, – Ni: 32.0 – 38.0% , – Mo: 2.0 – 3.0%, – Cu: 3.0 – 4.0% , – Other elements (C, Si, Mn, P, S, etc.) within specified limits |

| Tensile Strength (MPa) | ≥ 620 |

| Yield Strength (MPa) | ≥ 300 |

| Elongation at Break (%) | ≥ 40 |

| Forms Available | Coils, Sheets, Strips, etc. |

| Temper/Condition | Annealed, Solution Treated, etc. (depending on application) |

| Application | Chemical processing, Pollution control, Oil and gas production, etc. (due to its corrosion resistance and strength) |

Huaxiao Metal Manufacturer also provides other shapes of Incoloy products, such as bar,plate&sheet,wire&mesh, tube&pipe, strip. The price is affordable and suitable. Welcome to inqiure and learn more details about incoloy. You can click this button to fill in the basic information of this form. If you have any questions, you can describe them in detail.

What are the Benefits?

Many manufacturers offer customizable options for Incoloy alloy coils, including different thicknesses, widths, lengths, and surface finishes.This allows customers to tailor the material to their specific needs and applications. Incoloy alloy coils offer a combination of high temperature resistance, corrosion resistance, good processability, wide application range, strength and durability, cost-effectiveness, and compliance with international standards. These benefits make them an ideal choice for numerous industrial applications where these properties are critical. Welcome to Huaxiao Metal Manufacturer to requset the price, trust you can be satisfied in the alloy products.

Incoloy Alloy Coil Applications and Uses

Huaxiao Metal Supplier provides all kinds of incoloy alloy coils in the world. Welcome to inquiry.

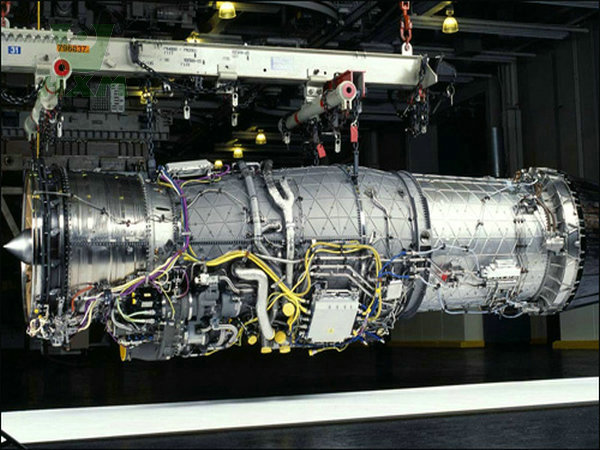

- Aerospace Industry:

- Components for jet engines, steam turbines, rocket engines, and other high-temperature environments.

- Parts requiring high strength and resistance to creep deformation at elevated temperatures.

- Chemical Industry:

- Reactors, piping systems, and storage tanks that need to withstand high temperatures and corrosive environments.

- Equipment for handling aggressive chemicals and acids.

- Energy Industry:

- Gas turbines, engine components, high-pressure pumps, and other equipment in power plants and oil refineries.

- Components exposed to high temperatures and corrosive media in fossil fuel and nuclear power generation.

Our experts will provide you with customized solutions. As a leading metal trading wholesaler in China, we will provide the best metals and services to our customers. Our company has many products with guaranteed quality, and of course, we can also provide customized services to offer you exclusive products. You can click this button to fill in the basic information of this form. If you have any questions, you can describe them in detail.

Incoloy Alloy Coil Advantages

Excellent Corrosion Resistance:

- Incoloy alloys exhibit high resistance to various corrosive media, including seawater, brine, sour gas, and high chloride environments.

- Specific Incoloy alloys, such as Incoloy 020, are particularly suitable for applications requiring sulfuric acid corrosion resistance.

High Temperature Strength:

- Incoloy alloys maintain high mechanical properties and strength at elevated temperatures, making them ideal for high-temperature environments.

- For instance, certain Incoloy alloys retain significant strength at temperatures up to 650°C, with good formability and weldability.

Good Processability:

- Incoloy alloys are typically easy to process using machines and techniques originally intended for stainless steel.

- This enhances the flexibility and efficiency of manufacturing processes involving Incoloy alloy coils.

Our experts will provide you with customized solutions. As a leading metal trading wholesaler in China, we will provide the best metals and services to our customers. Our company has many products with guaranteed quality, and of course, we can also provide customized services to offer you exclusive products. You can click this button to fill in the basic information of this form. If you have any questions, you can describe them in detail.

Outstanding Oxidation Resistance:

- Incoloy alloys possess excellent oxidation resistance, enabling them to maintain stable performance in high-temperature and oxidizing environments.

- This makes them suitable for equipment that operates in such conditions for extended periods.

Versatile Applications:

- Due to their unique performance advantages, Incoloy alloy coils find widespread use in multiple industrial sectors.

- For example, in the oil and gas industry, Incoloy alloys are among the most popular materials due to their tolerance of highly corrosive environments.

- In the aerospace industry, Incoloy alloys are used to manufacture critical components because of their high-temperature strength and corrosion resistance.

Cost-Effectiveness:

- Compared to some other high-performance alloys, Incoloy alloys may offer lower costs in certain scenarios.

- Especially when considering their excellent corrosion resistance, high-temperature strength, and processability, Incoloy alloys provide a high cost-performance ratio.

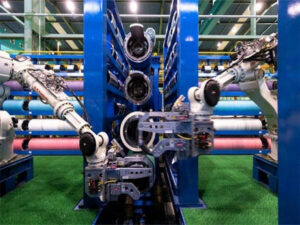

Alloy Factory

Huaxiao Metal Supplier provides professional services and reasonable prices, offering customers the best quality products. The Incoloy Alloy Coil Alloy Factory is a specialized manufacturing facility dedicated to the production of high-quality Incoloy alloy coils. This factory combines advanced technology, rigorous quality control, and experienced personnel to ensure the production of Incoloy alloy coils that meet the highest standards.The factory is equipped with state-of-the-art production equipment and machinery, capable of producing Incoloy alloy coil with precise dimensions and consistent quality.Welcome to reqiure, and ask to the price.

Our experts will provide you with customized solutions. As a leading metal trading wholesaler in China, we will provide the best metals and services to our customers. Our company has many products with guaranteed quality, and of course, we can also provide customized services to offer you exclusive products. You can click this button to fill in the basic information of this form. If you have any questions, you can describe them in detail.

You ask, we answer

We can provide small incoloy alloy plate&sheet samples for you to check the quality. The sample is free, you only need to pay the shipping cost.

Incoloy and Hastelloy are both nickel-based alloys with high corrosion resistance and mechanical strength. However, they differ in their chemical composition, properties, and applications. Incoloy is more cost-effective due to its higher iron content and is suitable for high-temperature applications, while Hastelloy offers superior corrosion resistance in severe environments and is primarily used in chemical processing and petrochemical industries.

Incoloy 800 alloy is a versatile nickel-iron-chromium alloy with a wide range of applications due to its high-temperature strength, corrosion resistance, and fabricability. Its unique chemical composition and properties make it an ideal material for demanding applications in various industries.