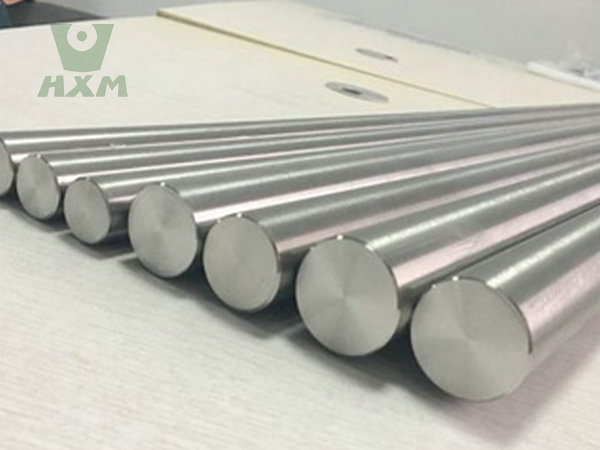

Incoloy Alloy Bar please note that the above table provides a range of standard thicknesses, widths, and lengths for Incoloy.

- Dimensions:

- Outside Diameter: 6-2500mm

- Length: 2000mm, 2500mm, 3000mm, 5800mm, 6000mm, 12000mm, etc

- Shapes: Angle, Hexagon, Square, Channel, Round, Flat etc.

- Finish: Bright, Polishing, Mirror, Hairline, Pickled, Peeled, Black

- *Customized size needs to be confirmed with us

- Grades: 800, 800H, 800HT, 803, 825, 832, 864, 890, 903, 907, 908, 909, 925, 926, 945, 945X, MA956, A-286, 020, 028,DS, 330, 25-6HN, 27-7MO.

Incoloy Alloy Bar Size And Specifications

Huaxiao Metal Supplier provides all sizes of incoloy alloy bar for sale. Customized specifications are available upon request. Additionally, the exact chemical composition and mechanical properties may vary slightly within the ranges listed, depending on the specific alloy formulation and production process. Custom sizes are also available upon request. Welcome to inquire, and learn about more details about the alloy bars.

| Alloy Grade | Diameter (mm) | Length (mm) | Shape | Standard |

|---|---|---|---|---|

| Incoloy 800 (UNS N08800) | 6 – 500 | 1000 – 6000 | Round, Square, Hex, etc. | ASTM B409, ASME SB409, etc. |

| Incoloy 800H (UNS N08810) | 5 – 300 | 1000 – 3000 | Round, Flat, etc. | ASTM B409, ASME SB409, etc. |

| Incoloy 800HT (UNS N08811) | 10 – 250 | 1000 – 3000 | Round, Square, etc. | ASTM B409, ASME SB409, etc. |

| Incoloy 825 (UNS N08825) | 6 – 500 | 1000 – 6000 | Round, Square, Hex, etc. | ASTM B424, ASME SB424, etc. |

| Incoloy 925 (UNS N09925) | 5 – 300 | 1000 – 3000 | Round, Flat, etc. | ASTM B619, ASME SB619, etc. |

| Incoloy A-286 (UNS S66286) | Customizable | Customizable | Round Bar, Square Bar, Hex Bar, etc. | AMS 5726, AMS 5731, ASTM A638, etc. |

Huaxiao Metal Manufacturer also provides other shapes of Incoloy products, such as coil,plate&sheet,wire&mesh, tube&pipe, strip. The price is affordable and suitable. Welcome to inqiure and learn more details about incoloy. Our experts will provide you with customized solutions. As a leading metal trading wholesaler in China, we will provide the best metals and services to our customers. Our company has many products with guaranteed quality, and of course, we can also provide customized services to offer you exclusive products. You can click this button to fill in the basic information of this form. If you have any questions, you can describe them in detail.

What are the Benefits?

Huaxiao Metal Manufacturer offers customizable options for Incoloy alloy bars, including different thicknesses, widths, lengths, and surface finishes.This allows customers to tailor the material to their specific needs and applications. Incoloy alloy bars offer a combination of corrosion resistance, high-temperature strength, good fabrication and weldability, wide range of applications, customizability, and long-term durability. These benefits make them an excellent choice for various applications in harsh environments where performance and reliability are critical. Welcome to Huaxiao Metal Manufacturer to requset the price, trust you can be satisfied in the alloy products.

Incoloy Alloy Bar Applications and Uses

Huaxiao Metal Supplier provides all kinds of incoloy alloy coils in the world. Welcome to inquiry.

Chemical Industry

- Corrosion-Resistant Equipment: Incoloy alloy bars are often used to manufacture equipment that is exposed to corrosive chemicals, such as tanks, reactors, and piping.

- Heat Exchangers: They are also used in heat exchangers where high temperatures and corrosive environments are present.

Oil and Gas Industry

- Refining Equipment: Incoloy alloy bars are suitable for use in refining equipment due to their ability to withstand high temperatures and corrosive media.

- Downhole Components: They are also used in downhole components in oil and gas wells, where resistance to hydrogen sulfide and other corrosive agents is crucial.

Aerospace Industry

- Engine Components: Incoloy alloy bars are used in the manufacture of engine components, such as turbine blades and nozzles, due to their high-temperature strength and corrosion resistance.

- Structural Components: They are also used in structural components that require lightweight and corrosion-resistant materials.

Our company has many products with guaranteed quality, and of course, we can also provide customized services to offer you exclusive products. You can click this button to fill in the basic information of this form. If you have any questions, you can describe them in detail. You can click this button to fill in the basic information of this form. If you have any questions, you can describe them in detail. Our experts will provide you with customized solutions. As a leading metal trading wholesaler in China, we will provide the best metals and services to our customers. Our experts will provide you with customized solutions. As a leading metal trading wholesaler in China, we will provide the best metals and services to our customers.

Incoloy Alloy Bar Advantages

Excellent Corrosion Resistance:

- Incoloy alloys are known for their ability to resist corrosion in a wide range of environments. This includes resistance to general corrosion, pitting, crevice corrosion, and stress corrosion cracking.

- The corrosion resistance of Incoloy alloys is due to their careful balance of elements such as nickel, chromium, molybdenum, and copper.

High Temperature Strength and Stability:

- Incoloy alloys maintain good mechanical properties and stability at elevated temperatures.

- They are often used in applications where high temperatures and corrosive environments are present, such as in oil and gas refining, chemical processing, and power generation.

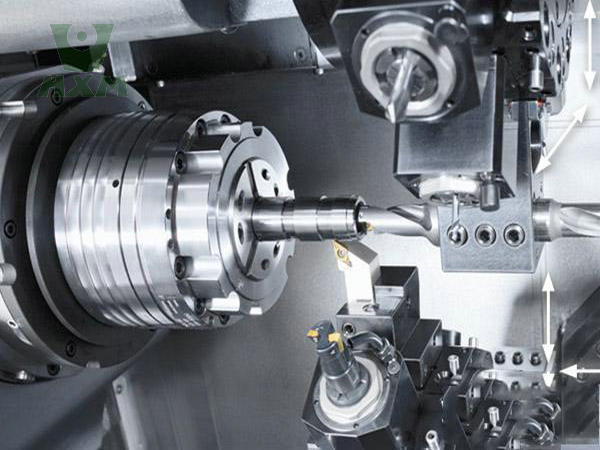

Good Fabrication and Weldability:

- Incoloy alloy bars can be easily processed and welded using conventional techniques.

- This makes them suitable for manufacturing various components and assemblies that require complex shapes and configurations.

Our company has many products with guaranteed quality, and of course, we can also provide customized services to offer you exclusive products. You can click this button to fill in the basic information of this form. If you have any questions, you can describe them in detail. You can click this button to fill in the basic information of this form. If you have any questions, you can describe them in detail. Our experts will provide you with customized solutions. As a leading metal trading wholesaler in China, we will provide the best metals and services to our customers. Our experts will provide you with customized solutions. As a leading metal trading wholesaler in China, we will provide the best metals and services to our customers.

Wide Range of Applications:

- Due to their corrosion resistance and high-temperature strength, Incoloy alloy bars are used in a wide range of industries.

- These include the chemical industry, oil and gas industry, aerospace industry, nuclear industry, and medical industry.

Customizable and Versatile:

- Incoloy alloy bars can be produced in various sizes, shapes, and specifications to meet specific application requirements.

- This versatility allows for the creation of custom solutions that cater to the unique needs of different industries and applications.

Long-term Durability and Reliability:

- Incoloy alloys are known for their long-term durability and reliability in harsh environments.

- They offer consistent performance over time, reducing the need for frequent maintenance and repairs.

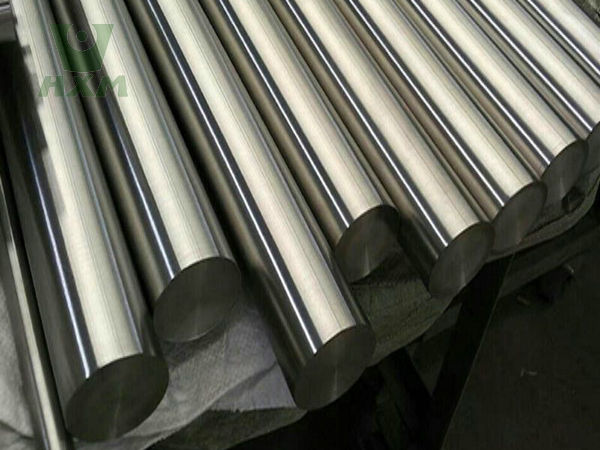

Alloy Factory

Huaxiao Metal Supplier provides professional services and reasonable prices, offering customers the best quality products. The Incoloy Alloy Bar Alloy Factory is a specialized manufacturing facility dedicated to the production of high-quality Incoloy alloy bars. This factory combines advanced technology, rigorous quality control, and experienced personnel to ensure the production of Incoloy alloy bars that meet the highest standards.The factory is equipped with state-of-the-art production equipment and machinery, capable of producing Incoloy alloy bar with precise dimensions and consistent quality.Welcome to reqiure, and ask to the price.

Our company has many products with guaranteed quality, and of course, we can also provide customized services to offer you exclusive products. You can click this button to fill in the basic information of this form. If you have any questions, you can describe them in detail. You can click this button to fill in the basic information of this form. If you have any questions, you can describe them in detail. Our experts will provide you with customized solutions. As a leading metal trading wholesaler in China, we will provide the best metals and services to our customers. Our experts will provide you with customized solutions. As a leading metal trading wholesaler in China, we will provide the best metals and services to our customers.

You ask, we answer

We can provide small incoloy alloy plate&sheet samples for you to check the quality. The sample is free, you only need to pay the shipping cost.

Incoloy and Hastelloy are both nickel-based alloys with high corrosion resistance and mechanical strength. However, they differ in their chemical composition, properties, and applications. Incoloy is more cost-effective due to its higher iron content and is suitable for high-temperature applications, while Hastelloy offers superior corrosion resistance in severe environments and is primarily used in chemical processing and petrochemical industries.

Incoloy 800 alloy is a versatile nickel-iron-chromium alloy with a wide range of applications due to its high-temperature strength, corrosion resistance, and fabricability. Its unique chemical composition and properties make it an ideal material for demanding applications in various industries.