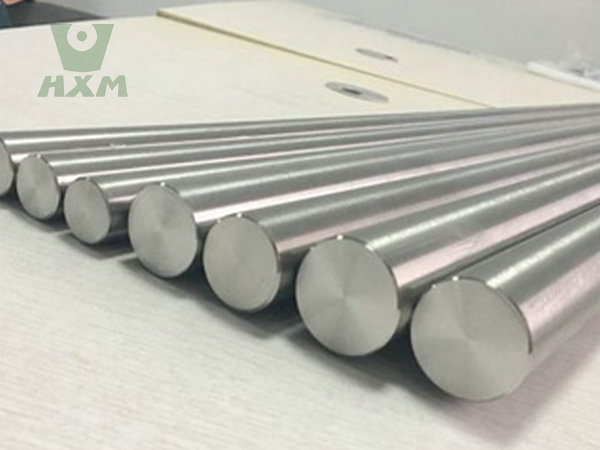

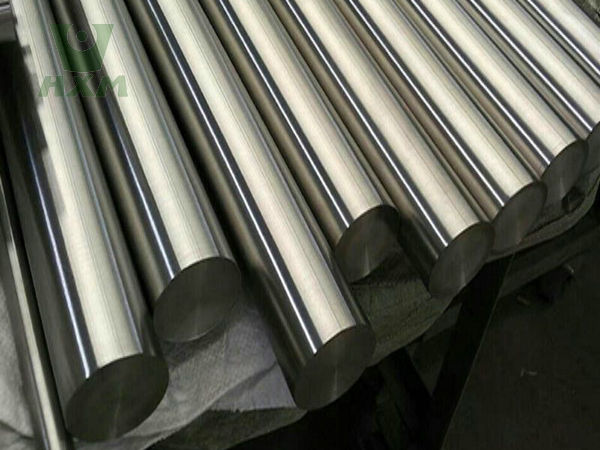

Incoloy A-286 Bar, please note that the below table, Huaxiao Metal Supplier provides a range of standard thicknesses, widths, and lengths for Incoloy Alloy Bar.

- Dimensions:

- Outside Diameter: 6-2500mm

- Length: 2000mm, 2500mm, 3000mm, 5800mm, 6000mm, 12000mm, etc

- Shapes: Angle, Hexagon, Square, Channel, Round, Flat etc.

- Finish: Bright, Polishing, Mirror, Hairline, Pickled, Peeled, Black

- Certification: ISO, SGS, BV and so on.

- Payment Term:L/C at sight, T/T, West Union ,

- Package:Export wooden pallets, Craft paper, Anti-Blushing Agent.

Incoloy A-286 Bar Data Sheets

Incoloy A-286 is a nickel-based alloy with additions of molybdenum, copper, and titanium, designed to provide exceptional resistance to corrosion in a wide range of environments, including acidic and alkaline conditions.Incoloy A-286 Bar is a premium-quality, precipitation-hardening nickel-iron-chromium alloy bar renowned for its superior mechanical properties, outstanding corrosion resistance, and excellent fabricability. This alloy, with its unique chemical composition and advanced processing techniques, finds extensive applications across various industries such as aerospace, marine engineering, petrochemicals, and more. Our company has the good service and delievery in China.

Incoloy A-286 Bar Standard Grades in Different Countries

Incoloy A-286 Bar is standardized under various international designations to ensure consistency and quality across global markets. Key standards include:

| Country | Standard Code/Number |

|---|---|

| United States | UNS S66286, ASTM A638, SAE AMS 5726, SAE AMS 5731, SAE AMS 5732, SAE AMS 5734, SAE AMS 5737, SAE AMS 5895 |

| Germany | W.Nr. 1.4980 |

| France | ZbNCT25, AECMA PrEn series (e.g., PrEn2171, PrEn2119, etc.) |

| United Kingdom | BS HR 51, BS HR 52, BS HR 650 |

| International (Aerospace) | SAE AMS series (as mentioned above), AECMA PrEn series (as mentioned above) |

Incoloy A-286 Bar is a nickel-based high-temperature alloy strip widely used in high-temperature and corrosive environments, particularly suitable for high-temperature equipment in the petrochemical, power, metallurgical, and aerospace industries. Huaxiao Metal Supplier provides all sizes of incoloy alloy strip for sale. Customized specifications are available upon request. Additionally, the exact chemical composition and mechanical properties may vary slightly within the ranges listed, depending on the specific alloy formulation and production process. Custom sizes are also available upon request. Welcome to inquire and ask for the lastest price, and learn about more details about the alloy strips. As a leading supplier & manufacturer in China, Huaxiao Metal supply cost-effective Incoloy A-286 Products.

Incoloy A-286 Bar Chemical Composition

Huaxiao Metal Manufacturer has the professional experts in alloy, and offer the free service for every customers. The chemical composition of Incoloy A-286 Bar is meticulously formulated to ensure its exceptional performance. The key elements and their respective ranges are listed in the table below:

| Element | Composition (%) |

|---|---|

| Nickel (Ni) | 24.0 – 27.0 |

| Chromium (Cr) | 13.5 – 16.0 |

| Iron (Fe) | Balance |

| Molybdenum (Mo) | 1.0 – 1.5 |

| Titanium (Ti) | 1.9 – 2.4 |

| Aluminum (Al) | ≤ 0.35 |

| Manganese (Mn) | ≤ 2.0 |

| Silicon (Si) | ≤ 1.0 |

| Carbon (C) | ≤ 0.08 |

| Sulfur (S) | ≤ 0.03 |

| Phosphorus (P) | ≤ 0.03 |

| Boron (B) | 0.001 – 0.01 |

Incoloy A-286 Bar Physical Properties

Incoloy A-286 exhibits a range of physical properties that make it suitable for demanding applications:

| Property | Value |

|---|---|

| Density | 7.94 g/cm³ (some sources specify 7.99 g/cm³) |

| Melting Point | 1370-1430°C (some sources specify 1364°C) |

| Specific Heat Capacity | 460 J/kg·°C |

| Thermal Expansion Coefficient | 17.2 µm/m·°C (20-300°C) |

| Thermal Conductivity | 12.7 W/m·°C |

| Electrical Resistivity | 0.91 Ω·mm²/m |

Huaxiao Metal Manufacturer has the good service and alloy and provides the solutions.

Incoloy A-286 Bar Nickel-Based Alloy Mechanical Properties

Our company has the good alloy in China. The mechanical properties of Incoloy A-286 bars are impressive, especially in high-stress environments:

| Property | Range/Value |

|---|---|

| Tensile Strength | 930-1180 MPa |

| Yield Strength (0.2% Offset) | ≥620 MPa (some sources specify 635 MPa or 590 MPa) |

| Elongation | ≥12% |

| Reduction of Area | ≥40% (for some heat-treated conditions) |

| Hardness | ≤32 HRC (some sources specify ≤341 HBS) |

The mechanical properties of Incoloy A-286 bar are outstanding. It exhibits high tensile strength, typically ranging from 930 to 1180 MPa, and yield strength of around 635 MPa. The elongation is at least 12%, demonstrating good ductility. Furthermore, Incoloy A-286 maintains excellent mechanical properties at elevated temperatures, up to 650°C, with high creep and rupture strength. These characteristics make it suitable for high-temperature applications in aerospace, chemical, and oil & gas industries. Huaxiao Metal Supplier has the good alloy products and service in China.

Huaxiao Metal Manufacturer also provides other shapes of Incoloy products, such as coil, plate&sheet, wire&mesh, tube&pipe, bar. The price is affordable and suitable. Welcome to inqiure and learn more details about incoloy.

Manufacturing Processes

Inconel A-286 Bar is typically produced through sophisticated melting and casting processes, followed by heat treatment, forging, rolling, and other forming operations to achieve the desired microstructure and properties. Surface treatment processes may also be applied to further enhance its performance in specific applications.

Furthermore, Incoloy A-286 Bar possesses excellent ductility, allowing it to be formed and shaped into various configurations without cracking or breaking. These mechanical properties, combined with its corrosion resistance and high-temperature stability, make Incoloy A-286 Bar an ideal choice for applications in harsh environments such as the oil and gas, chemical, and nuclear industries. Huaxiao Metal Manufacturer is the professional and experienced in processing alloy in China, which has the good services and fast delivery in transportation.

What are the Iron-Nickel-Chromium alloy Benefits?

Incoloy A-286 Bar, ensuring its suitability for high-temperature and corrosive environments. The material is widely used in industries such as chemical processing, power generation, and heat treatment due to its excellent oxidation resistance, carburization resistance, and thermal stability. It is resistant to a variety of corrosive media, including those containing sulfur and chlorine, at high temperatures and pressures. Welcome to Huaxiao Metal Manufacturer to request the price, trust you can be satisfied in the alloy Premium incoloy products and other alloy in China. The service is good and offer solutions.

Incoloy A-286 Bar Manufacturing Considerations

Huaxiao Metal Supplier provides all kinds of incoloy alloy coils in the world. Welcome to inquiry.

The production of Incoloy A-286 bars involves several key steps:

- Alloy Melting: High-purity raw materials are melted in an arc furnace or induction furnace, with precise control of alloy element additions.

- Casting: The molten alloy is cast into ingots, which are then cooled and prepared for further processing.

- Forging: The ingots are heated and shaped through forging to improve grain structure and mechanical properties.

- Hot Rolling: The forged billets are further processed into bars through hot rolling, which refines the grain structure and enhances mechanical properties.

- Annealing: To relieve internal stresses and improve ductility, the bars undergo annealing treatment.

- Cold Working and Finishing: Final dimensions and surface finish are achieved through cold working processes such as cutting, grinding, and polishing.

- Heat Treatment: Critical for final mechanical properties, including solution annealing and aging treatment to precipitate strengthening phases.

| Heat Treatment Step | Temperature Range (°C) | Time and Cooling Method |

|---|---|---|

| Solution Annealing | 980-1100 | Followed by rapid cooling (water quenching or oil quenching) |

| Aging Treatment | 600-760 | Typically 8-20 hours, followed by air cooling |

Incoloy A-286 Bar Advantages and Characristics

Advantages and Benefits

High Strength: Incoloy A-286 maintains high strength even at elevated temperatures.

Corrosion Resistance: Excellent resistance to a wide range of corrosive environments, including oxidation and sulfidation.

Weldability: Good weldability with standard welding techniques.

Fatigue Resistance: High resistance to fatigue and stress corrosion cracking.

Characteristics

High Temperature Performance: Suitable for use in environments up to 700°C.

Versatility: Can be used in a variety of industrial applications due to its balanced properties.

Longevity: Provides long-term durability and reliability in harsh conditions.

Cost Control

- Raw Material Costs: The cost of raw materials, especially nickel and chromium, is high.

- Production Efficiency: Improving production efficiency can reduce costs. This includes optimizing rolling and heat treatment processes, reducing waste, and improving material utilization.

- Scale of Production: Large-scale production can reduce unit costs due to economies of scale.

Production Flow

- Raw Material Preparation: Alloy materials are melted and cast into ingots.

- Hot Rolling: The ingots are hot-rolled into thicker plates or strips.

- Cold Rolling: The hot-rolled material is further cold-rolled to the desired thickness.

- Heat Treatment: The strips undergo heat treatment to optimize their microstructure and mechanical properties.

- Precision Finishing: Final finishing operations such as cutting, slitting, and surface treatment are performed.

- Quality Inspection: The strips undergo rigorous quality inspection to ensure they meet specified standards.

Incoloy A-286 Bar Applications and Uses

Due to its unique properties, Incoloy A-286 bars are widely used in:

- Aerospace Industry: Engine components such as turbine shells, combustion chambers.

- Chemical Industry: Reactors, heat exchangers, and other equipment exposed to corrosive environments.

- Energy Sector: Components in nuclear reactors and high-temperature, high-pressure pipelines in oil and gas exploration.

- Petroleum Industry: Drilling equipment and related accessories.

- Automotive Industry: High-temperature fasteners and turbocharger components.

Incoloy A-286 Bars are used in a variety of demanding applications across multiple industries.

| Industry | Applications | Examples |

|---|---|---|

| Heat Treating | Furnace components, muffles. | Withstands extreme heat and oxidation. |

| Chemical Processing | Reactors, heat exchangers, piping. | Resists corrosive chemicals and high temperatures. |

| Power Generation | Boiler tubes, superheaters. | Provides durability in high-pressure and high-temperature environments. |

| Aerospace | Turbine blades, exhaust systems. | Used in jet engines for its high-temperature resistance. |

| Electronics | Heating elements, thermocouples. | Offers reliable performance in electronic applications. |

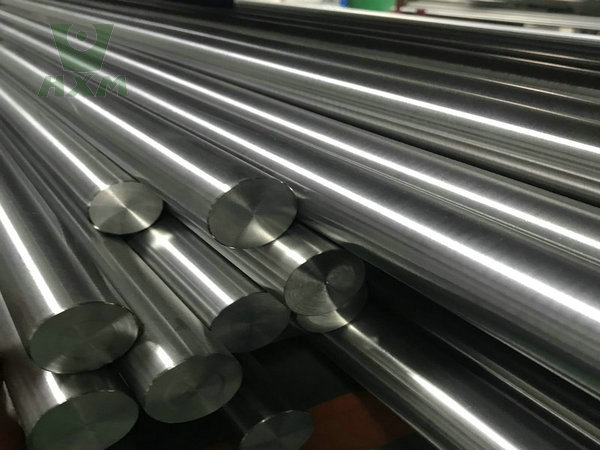

Alloy Factory

Huaxiao Metal Supplier provides professional services and reasonable prices, offering customers the best quality products. The Incoloy Alloy Bar Alloy Factory is a specialized manufacturing facility dedicated to the production of high-quality Incoloy alloy strips. This factory combines advanced technology, rigorous quality control, and experienced personnel to ensure the production of Incoloy alloy strips that meet the highest standards.The factory is equipped with state-of-the-art production equipment and machinery, capable of producing Incoloy alloy Bar with precise dimensions and consistent quality.Welcome to reqiure, and ask to the price.

Price Factors

The price of Inconel A-286 Bar is influenced by several factors, including the market price of nickel (its primary component), the high production and processing costs, and demand from industries such as aerospace, energy, and chemicals. Prices can vary significantly based on order size, supplier, and market conditions.

Inconel A-286 Bar is a versatile and high-performance alloy that plays a crucial role in numerous high-tech industries. Its unique combination of properties makes it an ideal material for applications requiring extreme durability and resistance to high temperatures and corrosive environments.

Why Choose The Incoloy A286 Bar?

Incoloy A-286 bars are a high-performance material designed for extreme environments. Their unique combination of chemical composition, physical properties, and mechanical strength makes them ideal for applications requiring resistance to high temperatures, oxidation, and corrosion. With a well-established manufacturing process, Incoloy A-286 bars deliver reliability and longevity in critical industries. Incoloy A-286 bar is a high-performance nickel-based alloy distinguished by its chemical composition, physical properties, mechanical properties, and numerous advantages. Its versatility makes it ideal for a wide range of applications in demanding environments, from petrochemicals to aerospace. The meticulous manufacturing process ensures consistent quality and reliability, making Incoloy A-286 bar a trusted material choice for industries worldwide.

Incoloy A-286 bars are a premium choice for applications requiring exceptional corrosion resistance and mechanical strength. Their ability to perform in a wide range of corrosive environments, combined with excellent fabricability and weldability, makes them indispensable in industries such as chemical processing, oil and gas, and marine engineering. The precise manufacturing process ensures that Incoloy A-286 bars meet the highest quality standards, providing reliable performance in the most demanding environments. Huaxiao Metal Supplier has all kinds of alloy products, the delivery is fast, the service has the customerized solutions for every customers and clients.

Incoloy A-286 bars offer a unique combination of high strength, excellent corrosion resistance, and good weldability, making them ideal for demanding applications in various industries. Their robust mechanical properties and versatility ensure long-term performance and reliability in harsh environments. Huaxiao Metal alloy products are good quality, Please contact us for any of your requirements.

As a leading supplier and manufacturer of high-performance alloys, we provide precision-ground Incoloy A286 bars in various sizes and custom specifications to meet your exact requirements, ensuring reliable quality and timely delivery for your critical projects.

Contact us today to request a quote or learn more about Incoloy A286 bar.

FAQ

Can you provide samples?

For small parts, we can provide free samples of regular sizes, but the shipping costs must be borne by you. For large samples, we will include it in the order amount. Please confirm with our sales department according to your specific requirements.

What does Incoloy A286 mean?

Incoloy A286 is a precipitation-hardenable nickel-iron-chromium superalloy engineered to deliver exceptional strength (1400+ MPa UTS) and oxidation resistance in extreme stress environments up to 704°C (1300°F). Its titanium/aluminum-enhanced chemistry enables reliable performance in critical aerospace fasteners, turbine components, and oil/gas downhole tools.

Do you support customized sizes?

We provide various forms such as plates, rods, and pipes, with a minimum processing accuracy of ± 0.02mm. The customization cycle is usually 7-15 working days, and specific details need to be confirmed with the sales team.

How long is your delivery time?

It is usually 35 days, but it is also affected by your specific requirements or order quantity.

What is the minimum order quantity?

Our minimum order quantity is 100kg. Larger quantity, lower price.

How do you control product quality?

From raw material selection to packaging for transport, each production step undergoes rigorous testing and evaluation. Only products that pass all tests are approved for export.