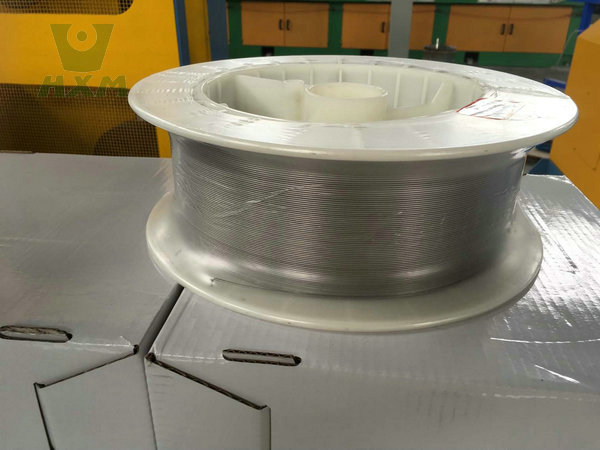

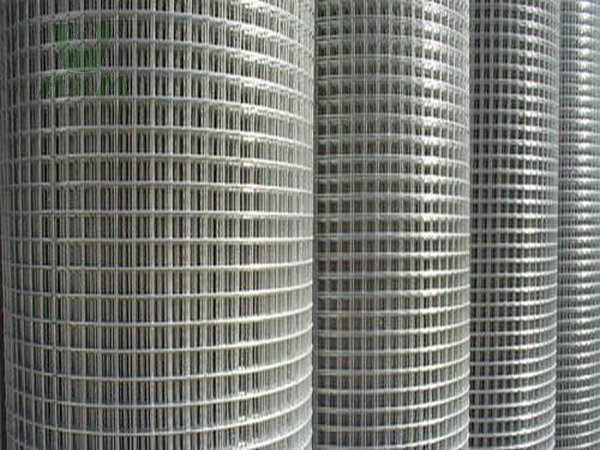

Incoloy 825 Wire & Mesh, please note that the above table, Huaxiao Metal Manufacturer is provides a range of standard roll width and lengths for Incoloy.

- Dimensions:

- Roll Width: 24inch, 36inch, 1Metre, 48inch, 72inch, or 84inch

- Roll Length: 100feet or 150feet

*Customized size needs to be confirmed with us

- Finish: Bright, Polishing, Mirror, Hairline, Pickled, Peeled, Black

- Certification: ISO, SGS, BV and so on.

- Payment Term:L/C at sight, T/T, West Union ,

- Package:Export wooden pallets, Craft paper, Anti-Blushing Agent.

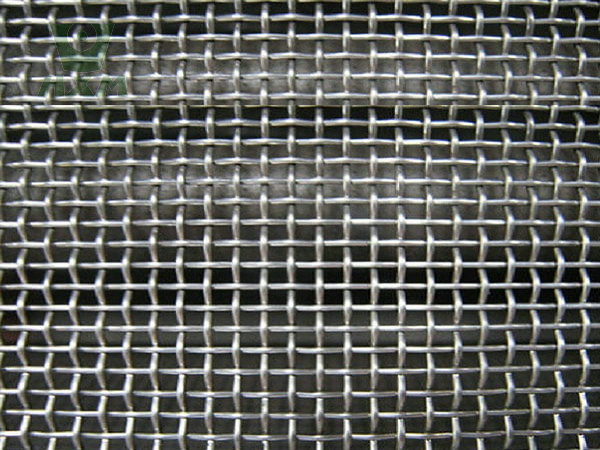

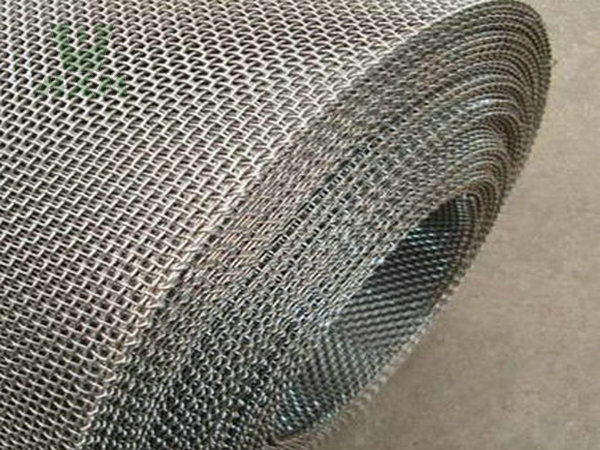

Incoloy metals 825 alloy wire mesh is a nickel-iron-chromium alloy renowned for its exceptional resistance to corrosion and high-temperature strength. Huaxiao Metal Supplier provides all sizes of incoloy alloy pipe for sale. Customized specifications are available upon request. Incoloy metals 825 wire mesh is a versatile and high-performance material made from Incoloy steel 825, a nickel-iron-chromium alloy known for its excellent resistance to oxidation, carburization, and high-temperature corrosion. The wire mesh form of Incoloy alloy 825 is widely used in filtration, separation, and high-temperature applications across industries such as chemical processing, power generation, and heat treatment. Contact us today quickly.

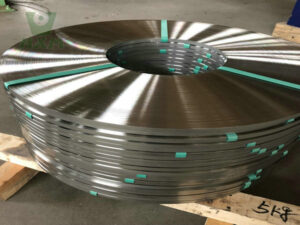

As the leading of metals supplier and manufacturer in China, our company has the good quality products and services.Welcome to inquire, and learn about more details about the alloy wire and mesh. Also, other shapes 825 alloy incoloy is for sale in China, such as pipe and tube, bar, strip and so on, you can click to the button to get more details.

Incoloy 825 Wire Data Sheets

Incoloy 825 Wire is a nickel-iron-chromium alloy known for its excellent resistance to oxidation, carburization, and other forms of high-temperature corrosion. It is widely used in industries that require materials to withstand extreme temperatures and corrosive environments. Below is a detailed analysis of Incoloy 825 wires and mesh, covering their chemical composition, physical properties, mechanical properties, advantages, characteristics, applications, and manufacturing processes.

Incoloy 825 Mesh Chemical Composition

The exceptional properties of Incoloy 825 wire mesh are attributed to its meticulously balanced chemical composition. The primary elements and their typical ranges are presented in the table below:

| Element | Composition Range (%) |

|---|---|

| Nickel (Ni) | 38.0 – 46.0 |

| Chromium (Cr) | 19.5 – 23.5 |

| Iron (Fe) | Balance (typically 22 – 28) |

| Molybdenum (Mo) | 2.5 – 3.5 |

| Copper (Cu) | 1.5 – 3.0 |

| Titanium (Ti) | 0.6 – 1.2 |

| Carbon (C) | ≤ 0.05 (or ≤ 0.025 in some specifications) |

| Silicon (Si) | ≤ 0.5 |

| Manganese (Mn) | ≤ 1.0 |

| Aluminum (Al) | 0.2 – 0.6 (in some specifications) |

| Sulfur (S) | ≤ 0.015 |

| Phosphorus (P) | ≤ 0.025 |

This detailed product introduction will analyze and describe Incoloy 825 wire mesh from aspects including chemical composition, physical properties, mechanical properties, advantages, characteristics, applications, and manufacturing process, accompanied by a table for clear illustration.

Incoloy 825 Wire Physical Properities

Incoloy 825 wire mesh exhibits a range of physical properties that make it suitable for demanding applications:

| Property | Value |

|---|---|

| Density | 8.14 g/cm³ |

| Melting Range | 1370 – 1400 °C |

| Thermal Expansion Coefficient | 14.0 µm/m°C (20-100°C) |

| Thermal Conductivity | 11.1 W/m·K |

| Electrical Resistivity | 1.12 µΩ·m |

- Density: Approximately 8.14 g/cm³

- Melting Point: 1370 – 1400°C

- Thermal Expansion Coefficient: Approximately 13.3 × 10⁻⁶/°C (at 20 – 100°C)

- Thermal Conductivity: Approximately 11.1 W/(m·K) at room temperature

These physical properties ensure stable performance under varying temperature conditions and good heat transfer capabilities. Huaxiao Metal Manufacturer has the complete factory line and the service is customerized for every customers. If you have any questions, you can consult to our experts freely, they will offer the best solutions for you.

Incoloy 825 Wire Mechanical Properities

The mechanical properties of Incoloy 825 wire mesh are impressive, especially in corrosive environments:

| Property | Value |

|---|---|

| Tensile Strength | ≥ 586 MPa |

| Yield Strength | ≥ 241 MPa |

| Elongation | ≥ 30% |

| Hardness (Rockwell B) | ≤ 90 HRB |

- Tensile Strength (Rm): ≥ 550 MPa (typically 580 – 750 MPa)

- Yield Strength (Rp0.2): Approximately 220 MPa (typically 240 – 345 MPa)

- Elongation (A5): Typically 30 – 40%

- Hardness (HB): Approximately 160 (may vary with heat treatment)

The alloy also exhibits excellent resistance to stress corrosion cracking, pitting corrosion, and crevice corrosion.

Huaxiao Metal Manufacturer also provides other shapes of Incoloy products, such as coil, plate&sheet, strip, wire&mesh, bar. The price is affordable and suitable. Welcome to inqiure and learn more details about incoloy. We have all the alloys you need. Welcome to place an order with our company. We believe you will meet our products and establish a long-term cooperation. We look forward to your inquiry.

What are the Incoloy 825 Mesh Benefits?

Incoloy 825 wire mesh offers a unique combination of excellent corrosion resistance, high-temperature performance, and good mechanical properties, making it ideal for demanding applications in various industries. Its robust performance and versatility ensure long-term reliability in harsh environments. Incoloy 825 wire mesh, with its optimized chemical composition, exceptional physical and mechanical properties, and superior corrosion resistance, is an ideal material for numerous demanding applications. Its versatile manufacturing process ensures high-quality products tailored to specific requirements. Whether in chemical processing, petroleum and natural gas, marine engineering, or other industries, Incoloy 825 wire mesh consistently demonstrates its reliability and performance excellence.

Huaxiao Metal Manufacturer offers customizable options for Incoloy alloy wires, including different thicknesses, widths, lengths, and surface finishes.This allows customers to tailor the material to their specific needs and applications. Incoloy 825 wire mesh, also known as UNS N08825, is a high-performance nickel-based alloy mesh material renowned for its exceptional corrosion resistance, mechanical properties, and versatility across various industrial applications. Welcome to Huaxiao Metal Manufacturer to request the price, trust you can be satisfied in the incoloy alloy products, and looking forward to our cooperation early.

Incoloy 825 Wire Advantages and Characteristics

Incoloy 825 wire mesh is a versatile and high-performance material suitable for a wide range of applications. Its chemical composition, physical properties, mechanical characteristics, and numerous advantages make it an ideal choice for industries requiring robust and reliable materials. The detailed manufacturing process ensures consistent quality and performance, making Incoloy 825 wire mesh a trusted solution for various industrial needs.

If you have any questions, you can consult to our staff and they will offer the solutions for you. Our company has the customerized service for you.

Advantages

Corrosion Resistance: Excellent resistance to both oxidizing and reducing environments, including sulfuric and phosphoric acids.

High Temperature Performance: Maintains mechanical properties at elevated temperatures.

Durability: High strength and resistance to wear and tear.

Versatility: Suitable for a wide range of industrial applications due to its balanced properties.

Characteristics

Oxidation Resistance: Superior resistance to oxidation at high temperatures.

Acid Resistance: Excellent resistance to sulfuric acid, phosphoric acid, and other corrosive media.

Thermal Stability: Maintains structural integrity under thermal cycling conditions.

Flexibility: Can be woven into various mesh sizes and patterns to meet specific application requirements.

Incoloy 825 Wire Applications and Uses

Incoloy 825 wire mesh offers a unique combination of high-temperature resistance, excellent corrosion resistance, and good mechanical properties, making it ideal for demanding applications in various industries. Its robust performance and versatility ensure long-term reliability in harsh environments. Huaxiao Metal Supplier will provide the good service and products in China.

Huaxiao Metal Supplier provides all kinds of incoloy alloy pipes in the world. Welcome to inquiry.

Incoloy 825 wire mesh is used in various industries, including:

Chemical Processing: Filtration and separation in corrosive environments.

Oil and Gas: Filtration in sour gas environments and offshore platforms.

Marine Engineering: Filtration and separation in seawater environments.

Power Generation: High-temperature filtration in boilers and turbines.

Pollution Control: Filtration in flue gas desulfurization systems.

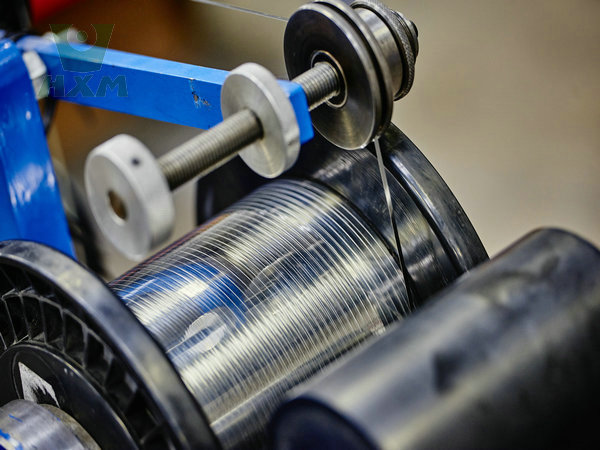

Incoloy 825 Wire Manufacturing Process

Huaxiao Metal has the professional factory and the experienced technology for processing the alloy.

The production of Incoloy 825 wire mesh involves several meticulous steps to ensure high quality and consistency:

- Raw Material Selection: Precise selection and blending of nickel, chromium, iron, molybdenum, copper, and other alloying elements.

- Melting and Refining: Melting the raw materials in an electric arc furnace, followed by refining processes to remove impurities.

- Casting: Pouring the molten alloy into molds to form ingots.

- Hot Rolling: Reducing the thickness of the ingots into wire rods through hot rolling.

- Cold Drawing: Further reducing the diameter of the wire rods to the desired size through cold drawing.

- Weaving: Forming the wire into mesh using weaving machines.

- Heat Treatment: Annealing or solution annealing to improve mechanical properties and corrosion resistance.

- Inspection and Testing: Chemical composition analysis, mechanical property testing, and surface quality inspection.

- Packaging and Shipping: Proper packaging to prevent damage during transportation and storage.

Alloy Factory

Huaxiao Metal Supplier provides professional services and reasonable prices, offering customers the best quality products. The Incoloy Alloy Wire Alloy Factory is a specialized manufacturing facility dedicated to the production of high-quality Incoloy alloy meshes. This factory combines advanced technology, rigorous quality control, and experienced personnel to ensure the production of Incoloy alloy wires that meet the highest standards.The factory is equipped with state-of-the-art production equipment and machinery, capable of producing Incoloy alloy wire with precise dimensions and consistent quality.Welcome to reqiure, and ask to the lastest price.

Why Choose Us?

Huaxiao Metal is the professional metals supplier and manufacturer in China, Our company’s products have been sold to more than 100 countries, and customer feedback has been very satisfied with my products. Most customers have repurchased my products again, forming stable trade relationships. We hope to cooperate soon.

Precision Manufacturing: ISO-certified production; strict compliance with ASTM B424. Tight tolerances (±0.01mm), superior surface finish.

Guaranteed Quality: Full traceability (MTRs with heat/lot tracking). Certified to NACE MR0175, PED, API 6A.

Ready Supply: Large stock (0.5–10mm), same-day shipping. Global DDP/DAP logistics support.

Proven Reliability: Trusted by oil/gas, chemical, nuclear sectors. Resists sour gas, acids, seawater.

Expert Partnership: 25+ years in superalloys; custom solutions.

FAQ

Can you provide samples?

For small parts, we can provide free samples of regular sizes, but the shipping costs must be borne by you. For large samples, we will include it in the order amount. Please confirm with our sales department according to your specific requirements.

What is the difference between Incoloy 825 and Incoloy 800?

Incoloy 825 and Incoloy 800 are both nickel-iron-chromium alloys but differ in composition and performance. Incoloy 825 and Incoloy 800 are both nickel-iron-chromium alloys but differ in composition and performance.

What are the characteristics of Incoloy 825 alloy?

Incoloy 825 is a nickel-iron-chromium alloy with added molybdenum, copper, and titanium. It offers excellent resistance to acid attack, particularly sulfuric and phosphoric acids. The alloy is highly resistant to pitting, crevice corrosion, and stress-corrosion cracking. Its mechanical properties remain stable in both high and low temperatures, making it suitable for harsh environments.

How long is your delivery time?

It is usually 35 days, but it is also affected by your specific requirements or order quantity.

What is the minimum order quantity?

Our minimum order quantity is 100kg. Larger quantity, lower price.

How do you control product quality?

From raw material selection to packaging for transport, each production step undergoes rigorous testing and evaluation. Only products that pass all tests are approved for export.