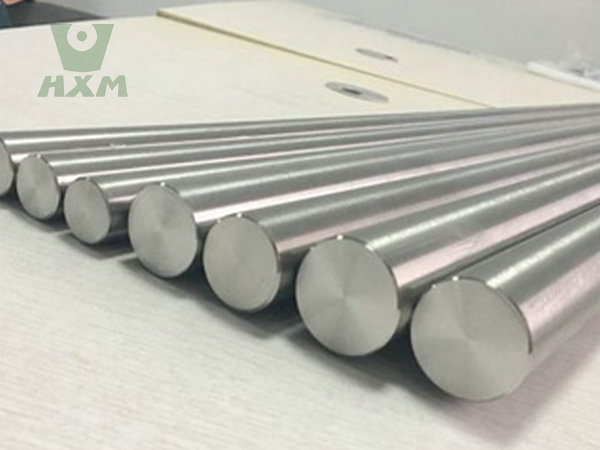

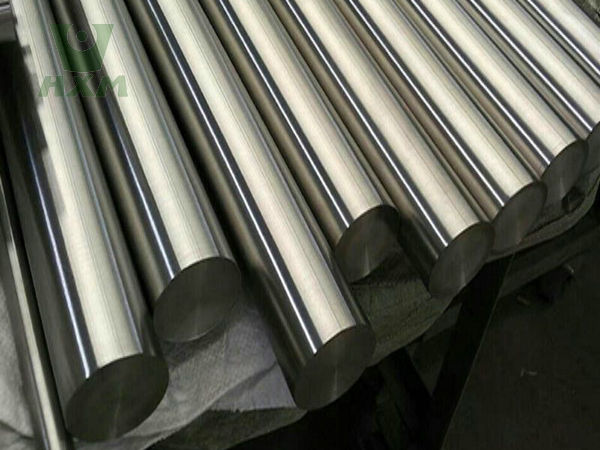

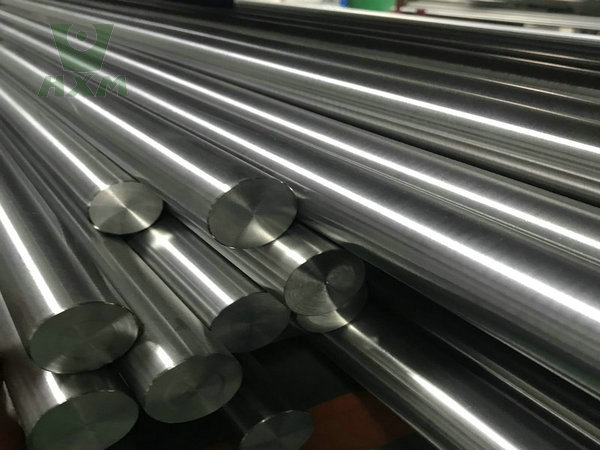

Incoloy 825 Bar please note that the above table, Huaxiao Metal Supplier provides a range of standard diameter and lengths for Incoloy bar.

- Outside Diameter: 6-2500mm

- Length: 2000mm, 2500mm, 3000mm, 5800mm, 6000mm, 12000mm, etc

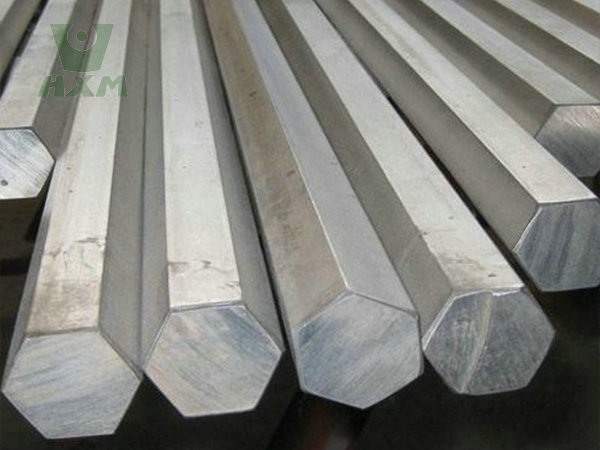

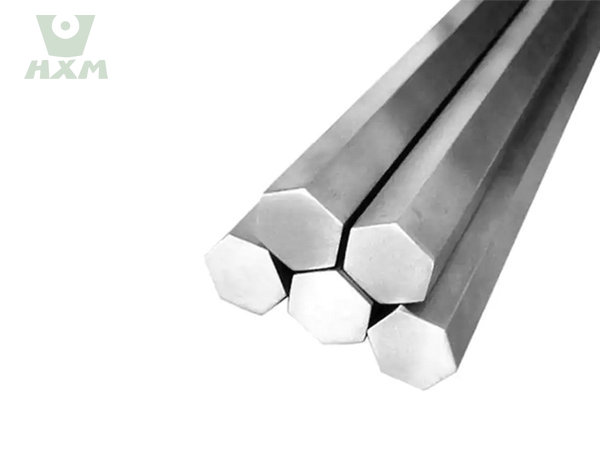

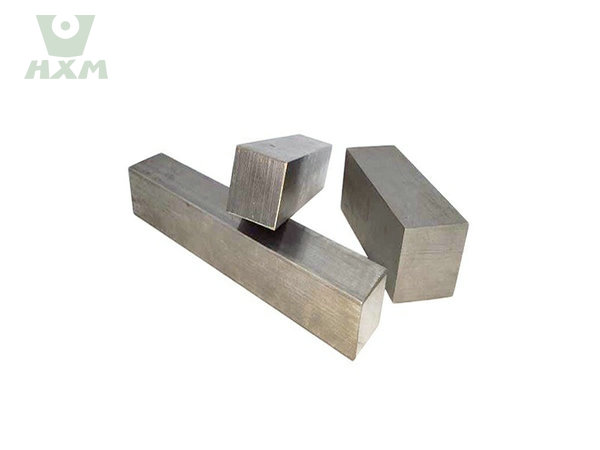

- Shapes: Angle, Hexagon, Square, Channel, Round, Flat etc.

*Customized size needs to be confirmed with us

- Finish: Bright, Polishing, Mirror, Hairline, Pickled, Peeled, Black

- Certification: ISO, SGS, BV and so on.

- Payment Term:L/C at sight, T/T, West Union ,

- Package:Export wooden pallets, Craft paper, Anti-Blushing Agent.

Incoloy 825 Bar is a nickel-based high-temperature alloy widely used in high-temperature and corrosive environments, particularly suitable for high-temperature equipment in the petrochemical, power, metallurgical, and aerospace industries. Huaxiao Metal Supplier provides all sizes of incoloy alloy bar for sale. Customized specifications are available upon request. Additionally, the exact chemical composition and mechanical properties may vary slightly within the ranges listed, depending on the specific alloy formulation and production process. Custom sizes are also available upon request. Welcome to inquire and ask for the lastest price, and learn about more details about the alloy bars.

As a leading supplier & manufacturer in China, Huaxiao Metal supply cost-effective Incoloy 825 Products, such as 825 wire and mesh, 825 pipe and tube, 825 strip and so on, welcome to inquire and ask for the lastest price quickly.

Incoloy 825 Bar Data Sheets

Incoloy 825 is a nickel-iron-chromium alloy with additions of molybdenum, copper, and titanium, designed to provide exceptional resistance to corrosion in a wide range of environments, including acidic and alkaline conditions. It is particularly well-suited for applications in chemical processing, oil and gas, and marine industries. This product introduction will provide a detailed analysis of the chemical composition, physical properties, mechanical properties, advantages, characteristics, applications, and manufacturing process of Incoloy 825 bars.

Incoloy 825 Bar Chemical Composition

The chemical composition of Incoloy 825 Bar is carefully formulated to deliver superior corrosion resistance and mechanical strength. Below is a table detailing its composition:

| Element | Composition (%) |

|---|---|

| Nickel (Ni) | 38.0 – 46.0 |

| Chromium (Cr) | 19.5 – 23.5 |

| Iron (Fe) | Balance |

| Molybdenum (Mo) | 2.5 – 3.5 |

| Copper (Cu) | 1.5 – 3.0 |

| Titanium (Ti) | 0.6 – 1.2 |

| Manganese (Mn) | ≤ 1.00 |

| Silicon (Si) | ≤ 0.50 |

| Carbon (C) | ≤ 0.05 |

| Sulfur (S) | ≤ 0.03 |

The high nickel content provides excellent resistance to reducing environments, while chromium enhances resistance to oxidizing conditions. Molybdenum and copper improve resistance to localized corrosion, such as pitting and crevice corrosion, in chloride-containing environments. Huaxiao Metal Manufacturer is the professional and experienced in processing incoloy alloy bar in China, our company has the various alloy products and the quality and service are good. If you have any questions about incoloy, you can consult our experts and they will provide the solutuion to you for free. Looking forward to our trade and set up the long-term cooperation relationship.

Incoloy 825 Bar Physical Properties

Incoloy 825 bar exhibits a range of physical properties that make it suitable for demanding applications. Key physical properties are listed below:

| Property | Value |

|---|---|

| Density | 8.14 g/cm³ |

| Melting Range | 1370 – 1400 °C |

| Thermal Conductivity | 11.1 W/m·K (at 100 °C) |

| Specific Heat Capacity | 440 J/kg·K (at 20 °C) |

| Electrical Resistivity | 1.12 µΩ·m (at 20 °C) |

| Coefficient of Thermal Expansion | 14.0 µm/m·K (20 – 100 °C) |

Incoloy 825 bar is a versatile, high-performance alloy bar with exceptional corrosion resistance, high-temperature stability, and superior mechanical properties. Its wide range of applications across various industries underscores its importance and value. Huaxiao Metal Manufacturer has the good service and alloy and provides the solutions.

Incoloy 825 Bar Nickel Alloy Mechanical Properties

Incoloy 825 bars exhibit excellent mechanical properties, ensuring reliability in harsh environments. The following table summarizes its mechanical properties:

| Property | Value |

|---|---|

| Tensile Strength | 586 – 689 MPa |

| Yield Strength (0.2% Offset) | 241 – 345 MPa |

| Elongation | 30 – 50% |

| Hardness (Rockwell B) | 80 – 95 HRB |

| Modulus of Elasticity | 200 GPa |

These properties ensure that Incoloy 825 bars can withstand significant mechanical stress and deformation in corrosive environments. Incoloy 825 bar is a high-performance nickel-based alloy bar known for its exceptional corrosion resistance, high-temperature stability, and superior mechanical properties. Our company has the good alloy in China.

Huaxiao Metal Manufacturer also provides other shapes of Incoloy products, such as coil, plate&sheet, wire&mesh, tube&pipe, bar. The price is affordable and suitable. Welcome to inqiure and learn more details about incoloy.

Furthermore, Incoloy 825 Bar possesses excellent ductility, allowing it to be formed and shaped into various configurations without cracking or breaking. These mechanical properties, combined with its corrosion resistance and high-temperature stability, make Incoloy 825 Bar an ideal choice for applications in harsh environments such as the oil and gas, chemical, and nuclear industries. Huaxiao Metal Manufacturer is the professional and experienced in processing alloy in China, which has the good services and fast delivery in transportation.

What are the nickel-iron-chromium alloy Benefits?

Incoloy 825 Bar, ensuring its suitability for high-temperature and corrosive environments. The material is widely used in industries such as chemical processing, power generation, and heat treatment due to its excellent oxidation resistance, carburization resistance, and thermal stability. Compliance with these standards guarantees consistent quality and performance across global applications.It is resistant to a variety of corrosive media, including those containing sulfur and chlorine. Welcome to Huaxiao Metal Supplier to request the price, trust you can be satisfied in the alloy incoloy products in China.

Incoloy 825 Bar Manufacturing Considerations

Huaxiao Metal Supplier provides all kinds of incoloy alloy coils in the world. Welcome to inquiry.

The production of Incoloy 825 bars involves several critical steps to ensure the material meets the required specifications:

Melting: The raw materials are melted in an electric arc furnace or vacuum induction furnace to achieve the desired chemical composition.

Casting: The molten alloy is cast into billets or ingots.

Hot Working: The billets are heated and hot-rolled or forged into bars.

Cold Working: Cold drawing or rolling is performed to achieve the final dimensions and surface finish.

Heat Treatment: Solution annealing is carried out to optimize the microstructure and mechanical properties.

Surface Treatment: The bars are pickled and passivated to enhance corrosion resistance.

Inspection and Testing: The bars undergo rigorous testing, including chemical analysis, mechanical testing, and non-destructive testing (NDT), to ensure quality.

Incoloy 825 Bar Advantages and Characristics

Incoloy 825 bars are a premium choice for applications requiring exceptional corrosion resistance and mechanical strength. Their ability to perform in a wide range of corrosive environments, combined with excellent fabricability and weldability, makes them indispensable in industries such as chemical processing, oil and gas, and marine engineering. The precise manufacturing process ensures that Incoloy 825 bars meet the highest quality standards, providing reliable performance in the most demanding environments. Huaxiao Metal Supplier has all kinds of alloy products, the delivery is fast, the service has the customerized solutions for every customers and clients.

Advantages:

Corrosion Resistance: Excellent resistance to both reducing and oxidizing acids, as well as stress corrosion cracking in chloride-containing environments.

High-Temperature Performance: Maintains mechanical properties at elevated temperatures.

Versatility: Suitable for a wide range of corrosive environments, including sulfuric and phosphoric acids, seawater, and alkaline solutions.

Weldability: Can be easily welded using common techniques, such as TIG and MIG welding.

Fabricability: Can be readily formed and machined into complex shapes.

Characteristics:

Superior resistance to pitting, crevice corrosion, and intergranular corrosion.

Good thermal stability and oxidation resistance.

Excellent performance in both acidic and alkaline environments.

Incoloy 825 Bar Applications and Uses

Incoloy 825 bars are a high-performance material designed for extreme environments. Their unique combination of chemical composition, physical properties, and mechanical strength makes them ideal for applications requiring resistance to high temperatures, oxidation, and corrosion. With a well-established manufacturing process, Incoloy 825 bars deliver reliability and longevity in critical industries. Incoloy 825 bar is a high-performance nickel-based alloy distinguished by its chemical composition, physical properties, mechanical properties, and numerous advantages. Its versatility makes it ideal for a wide range of applications in demanding environments, from petrochemicals to aerospace. The meticulous manufacturing process ensures consistent quality and reliability, making Incoloy 800 bar a trusted material choice for industries worldwide. Welcome to inquire and ask for the lastest price for sale.

Incoloy 825 bars are widely used in industries requiring materials that can withstand corrosive environments. Key applications include:

Chemical Processing: Reactors, heat exchangers, and piping systems for handling sulfuric acid, phosphoric acid, and other corrosive chemicals.

Oil and Gas: Downhole components, pipelines, and valves for sour gas environments.

Marine Industry: Seawater handling equipment, such as pumps, valves, and heat exchangers.

Pollution Control: Scrubbers and waste treatment systems.

Nuclear Fuel Reprocessing: Equipment for handling radioactive waste and corrosive byproducts.

Incoloy 825 Bars are used in a variety of demanding applications across multiple industries.

| Industry | Applications | Examples |

|---|---|---|

| Heat Treating | Furnace components, muffles. | Withstands extreme heat and oxidation. |

| Chemical Processing | Reactors, heat exchangers, piping. | Resists corrosive chemicals and high temperatures. |

| Power Generation | Boiler tubes, superheaters. | Provides durability in high-pressure and high-temperature environments. |

| Aerospace | Turbine blades, exhaust systems. | Used in jet engines for its high-temperature resistance. |

| Electronics | Heating elements, thermocouples. | Offers reliable performance in electronic applications. |

Alloy Factory

Huaxiao Metal Supplier provides professional services and reasonable prices, offering customers the best quality products. The Incoloy Alloy Bar Alloy Factory is a specialized manufacturing facility dedicated to the production of high-quality Incoloy alloy strips. This factory combines advanced technology, rigorous quality control, and experienced personnel to ensure the production of Incoloy alloy strips that meet the highest standards.The factory is equipped with state-of-the-art production equipment and machinery, capable of producing Incoloy alloy Bar with precise dimensions and consistent quality.Welcome to reqiure, and ask to the price.

Price Factors

The price of Inconel 825 Bar is influenced by several factors, including the market price of nickel (its primary component), the high production and processing costs, and demand from industries such as aerospace, energy, and chemicals. Prices can vary significantly based on order size, supplier, and market conditions.

Inconel 825 Bar is a versatile and high-performance alloy that plays a crucial role in numerous high-tech industries. Its unique combination of properties makes it an ideal material for applications requiring extreme durability and resistance to high temperatures and corrosive environments.

Incoloy 825 Bar is produced by various manufacturers worldwide, who employ advanced production processes and quality control measures to ensure consistent performance and quality. These factories can provide a range of specifications, including seamless tubes, steel plates, round bars, forgings, flanges, rings, welded tubes, steel strips, and wires. Customized production services are also available to meet specific customer requirements. Several alloy manufacturers specialize in producing Incoloy 825 bar, adhering to stringent standards to ensure quality and safety. These manufacturers often follow specifications such as ASTM B435, UNS N08330, and ISO 9453, ensuring the material’s traceability and consistency.

Why Choose Us?

Incoloy 825 Bar is a versatile nickel-iron-chromium alloy with excellent high-temperature resistance, oxidation resistance, and corrosion resistance. Its optimized manufacturing process and cost-control measures ensure high-quality production at competitive costs. This material is ideal for demanding applications in chemical processing, power generation, and heat treatment industries, where reliability and performance under extreme conditions are critical.Huaxiao Metal alloy products are good quality, Please contact us for any of your requirements.

Specialized Inventory: Stock10+ Incoloy grades 825 in all forms: bar, plate, tube, fittings, and others.

Certified Quality: EN 10204 3.2 certs + PMI testing guarantee composition accuracy, such as SGS, ISO, MTR.

Technical Expertise: Engineers provide material selection guidance and welding parameters.

Cost Efficiency:Direct mill pricing cuts 15-25% vs. distributors.

Rapid Logistics: Global shipping with 15-day lead time (ISO-compliant packaging).

FAQ

Can you provide samples?

For small parts, we can provide free samples of regular sizes, but the shipping costs must be borne by you. For large samples, we will include it in the order amount. Please confirm with our sales department according to your specific requirements.

What is the difference between Incoloy 825 and Incoloy 800?

Incoloy 825 and Incoloy 800 are both nickel-iron-chromium alloys but differ in composition and performance. Incoloy 825 and Incoloy 800 are both nickel-iron-chromium alloys but differ in composition and performance.

Can your 825 bar be welded? What welding rod should be used?

Yes, Inconel 825 bars are weldable using ERNiCrMo-3 (AWS A5.14) filler rod/wire for TIG or stick welding. This nickel-chromium-molybdenum alloy electrode ensures matching corrosion resistance and prevents hot cracking.

How long is your delivery time?

It is usually 35 days, but it is also affected by your specific requirements or order quantity.

What is the minimum order quantity?

Our minimum order quantity is 100kg. Larger quantity, lower price.

How do you control product quality?

From raw material selection to packaging for transport, each production step undergoes rigorous testing and evaluation. Only products that pass all tests are approved for export.