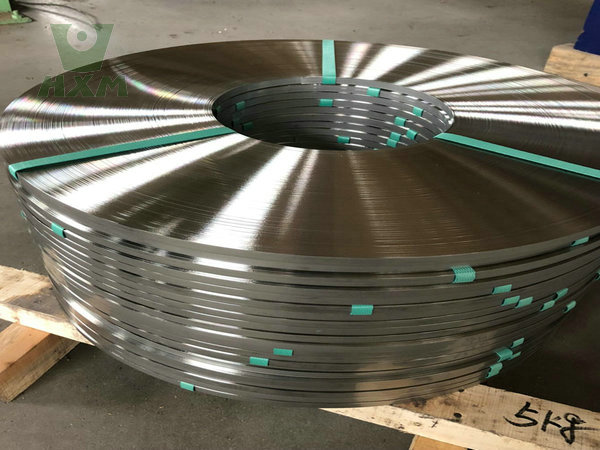

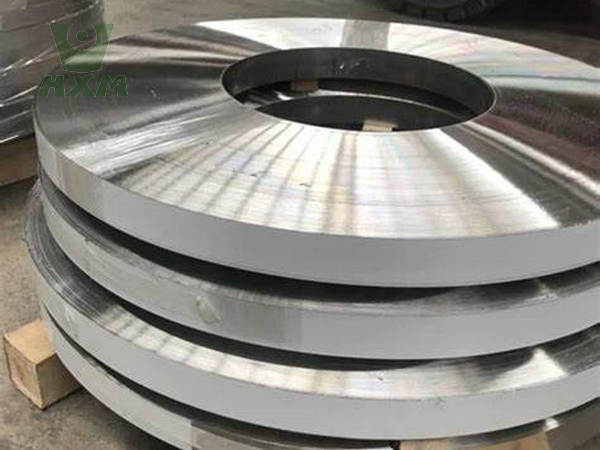

Incoloy 800 Strip nickel alloy, please note that the above table, Huaxiaopp Metal Manufacturer provides a range of standard thicknesses, and widths for Incoloy.

- Dimensions:

- Thickness: 0.3-200mm

- Width:<600mm,

- *Customized size needs to be confirmed with us

- Payment Term:L/C at sight, T/T, West Union ,

- Package:Export wooden pallets, Craft paper, Anti-Blushing Agent.

- Delivery Time: Future goods: Also 30 Work days, Ready Stock:7-15 days.

- Certification: ISO, SGS, BV and so on.

- ASTM B409 UNS N08800, ASME SB409, ASTM B409 UNS N08810, ASTM B409 UNS N08811

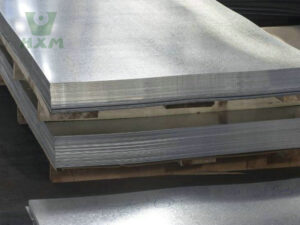

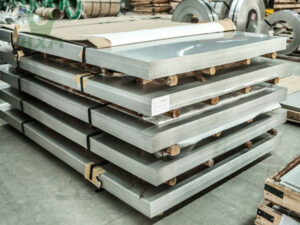

Huaxiao Metal has incoloy 800 metal in other shapes, such as wire, pipe, bar, plate. If you have a need for incoloy metal, please feel free to contact our company. Our products come with quality inspection certificates and licenses, so you can purchase with confidence. We believe you will be satisfied with our products and establish a long-term cooperation with us. Of course, if you want to learn more about metal related knowledge and information, please feel free to contact our expert services through our website. We believe you will gain something from it.

Overview of Incoloy 800 Strip

The mechanical properties of Incoloy 800 strip are essential for its durability and performance in demanding environments. These properties include:

- High Ductility and Toughness: Ability to absorb energy and resist damage under external forces

- Good Creep Resistance: Maintains mechanical properties at elevated temperatures with minimal deformation

Incoloy 800 Strip is a nickel-based high-temperature alloy strip widely used in high-temperature and corrosive environments, particularly suitable for high-temperature equipment in the petrochemical, power, metallurgical, and aerospace industries. Huaxiao Metal Supplier provides all sizes of incoloy alloy strip for sale. Customized specifications are available upon request. depending on the specific alloy formulation and production process. Custom sizes are also available upon request. Welcome to inquire and ask for the lastest price, and learn about more details about the alloy strips. As a leading supplier & manufacturer in China, Huaxiao Metal supply cost-effective Incoloy 800 Products.

Incoloy 800 strip is standardized under various international designations to ensure consistency and quality across global markets. Key standards include:

UNS Number: N08800 (Unified Numbering System, USA)

ASTM: B409 (Standard Specification for Nickel-Iron-Chromium Alloy Plate, Sheet, and Strip)

EN (European Norm): 1.4876 (X10NiCrAlTi32-20)

DIN (Germany): W.Nr. 1.4876

JIS (Japan): NCF 800

GB (China): GH1800

Incoloy 800 Strip Chemical Composition

| Element | Percentage (%) |

|---|---|

| Ni | 30-35 |

| Cr | 19-23 |

| Fe | 39.5 (min) |

| C | ≤0.10 |

| Mn | ≤1.5 |

| Si | ≤1.0 |

| S | ≤0.015 |

| Cu | ≤0.75 |

| Ti | 0.15-0.60 |

| Al | 0.15-0.60 |

Huaxiao Metal Manufacturer is the professional and experienced in processing incoloy alloy strip in China. Our company has the good quality incoloy 800 strip and the service is customerized for every clients. If you want to learn about the incoloy 800, welcome to you consult our experts and they will provide the solution for free. Of course, you can click the green button, make the list and quickly contact us today, our staff will reply you within 24 hours.

Incoloy 800 Strip Physical Properties

| Property | Value |

|---|---|

| Density | 7.94 g/cm³ |

| Melting Point | 1350-1400°C |

| Thermal Expansion Coefficient | 14.4 µm/m°C (20-100°C) |

| Thermal Conductivity | 11.8 W/m·K (100°C) |

| Electrical Resistivity | 1.03 µΩ·m (20°C) |

- Density: Approximately 7.9-8.0 g/cm³.

- Thermal Expansion Coefficient: Typically 13×10^-6/K within the range of 20°C to 1000°C.

- Thermal Conductivity: Relatively low, significantly lower than pure nickel and copper materials at higher temperatures.

- Electrical Conductivity: Lower electrical conductivity, suitable for applications where electrical performance requirements are not high.

Whether you’re developing a new product or ramping up production, we’ll be happy to learn more about your specific needs. Please fill out the form below, and we will promptly get back to you with a quote or, if needed, a request for more information.

Incoloy 800 Strip Nickel Alloy Mechanical Properties

| Property | Value |

|---|---|

| Tensile Strength | 500-700 MPa |

| Yield Strength | 200-400 MPa |

| Elongation | 30-45% |

| Hardness | 150-200 HV |

- High-Temperature Strength: Maintains excellent strength at high temperatures, with good mechanical properties in the range of 800-1000°C.

- Creep Resistance: Excellent creep resistance due to the presence of chromium, titanium, and other elements that enhance grain boundary strength.

- Fatigue Resistance: Good fatigue resistance, effectively resisting crack propagation under high-temperature and alternating load conditions.

- Corrosion Resistance: Excellent corrosion resistance in various corrosive environments, particularly resistant to acidic gases and high-temperature oxidation.

Huaxiao Metal Manufacturer also provides other shapes of Incoloy products, such as coil, plate&sheet, wire&mesh, tube&pipe, bar. The price is affordable and suitable. Welcome to inqiure and learn more details about incoloy.

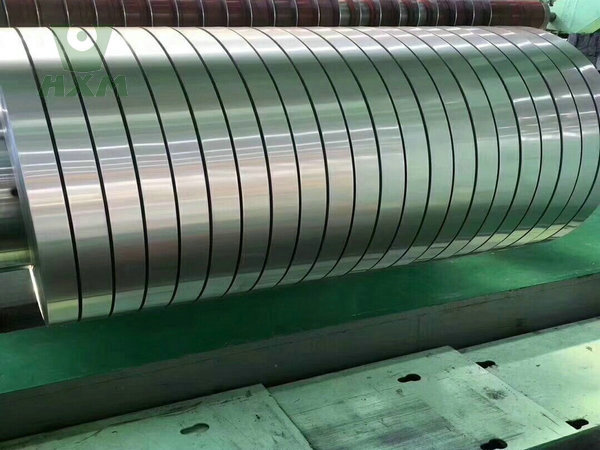

Manufacturing Processes

Inconel 800 Strip is typically produced through sophisticated melting and casting processes, followed by heat treatment, forging, rolling, and other forming operations to achieve the desired microstructure and properties. Surface treatment processes may also be applied to further enhance its performance in specific applications.

What are the Nickel Alloy 800 Benefits?

Nickel alloy800 offer a unique combination of strength, corrosion resistance, and heat resistance, making them ideal for demanding industrial applications. These alloys maintain excellent mechanical properties at both high and low temperatures, ensuring durability in extreme environments. Nickel enhances resistance to oxidation, acid attack, and stress corrosion cracking, especially in marine, chemical, and high-temperature settings, nickel alloys help extend equipment life, reduce maintenance costs, and ensure operational safety.Welcome to Huaxiao Metal Manufacturer to request the price, trust you can be satisfied in the alloy Premium incoloy products and other alloy in China.

Incoloy 800 Strip Manufacturing Considerations

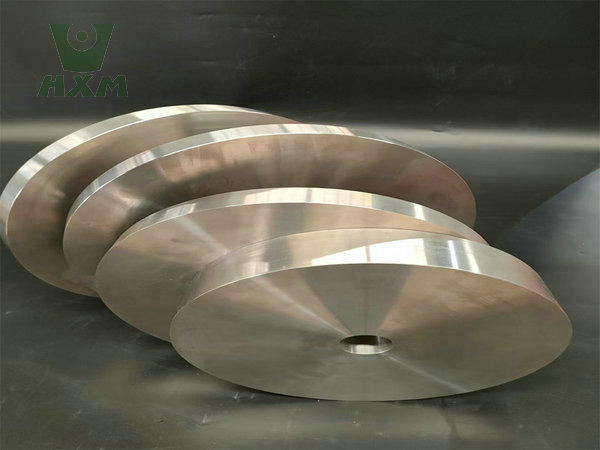

Huaxiao Metal Supplier provides all kinds of incoloy alloy coils in the world. Welcome to inquiry.

Producing Incoloy 800 strips involves several critical steps to ensure quality and performance.

Manufacturing Processes

- Raw Material Preparation: Alloy materials are melted and cast into large alloy ingots.

- Rolling and Heat Treatment: Processed into strips through multiple hot rolling, cold rolling, and heat treatment processes.

- Precision Finishing: Final finishing operations such as cutting, slitting, and surface treatment are performed to meet specific application requirements.

Cost Control

- Raw Material Costs: The cost of raw materials, especially nickel and chromium, is high.

- Production Efficiency: Improving production efficiency can reduce costs. This includes optimizing rolling and heat treatment processes, reducing waste, and improving material utilization.

- Scale of Production: Large-scale production can reduce unit costs due to economies of scale.

Production Flow

- Raw Material Preparation: Alloy materials are melted and cast into ingots.

- Hot Rolling: The ingots are hot-rolled into thicker plates or strips.

- Cold Rolling: The hot-rolled material is further cold-rolled to the desired thickness.

- Heat Treatment: The strips undergo heat treatment to optimize their microstructure and mechanical properties.

- Precision Finishing: Final finishing operations such as cutting, slitting, and surface treatment are performed.

- Quality Inspection: The strips undergo rigorous quality inspection to ensure they meet specified standards.

Incoloy 800 Strip Advantages

Incoloy 800 strip is renowned for its exceptional characteristics and advantages:

- Excellent High-Temperature Performance: Can maintain good mechanical properties between 700°C and 1000°C.

- Good Corrosion Resistance: Forms a protective oxide film on the surface to prevent further oxide expansion.

- Good Weldability: Can be welded using traditional welding methods such as TIG and MIG.

- Good Processing Performance: Suitable for cutting, milling, and other processing.

Versatility: Suitable for a wide range of applications, including heat exchangers, furnace components, and chemical processing equipment.

Durability: Long service life in high-temperature and corrosive environments.

Weldability: Can be welded using common methods without significant loss of properties.

Cost-Effectiveness: Provides a balance of performance and cost for high-temperature applications.

| Advantage | Description |

|---|---|

| High-Temperature Resistance | Maintains strength and resists oxidation at high temperatures. |

| Excellent Corrosion Resistance | Resists a wide range of corrosive environments, including acids, alkalis, and chlorides. |

| Versatility in Fabrication | Easily formed and welded, allowing for versatile use in various applications. |

| Mechanical Properties | High strength and ductility, suitable for high-stress applications. |

| Longevity and Durability | Long service life and low maintenance requirements, reducing downtime and costs. |

| Cost-Effectiveness | Reduced replacement costs and efficient manufacturing processes. |

Incoloy 800 Strip Applications and Uses

Incoloy 800 strip finds widespread application in various industries due to its superior properties.

Due to its outstanding combination of high-temperature performance, corrosion resistance, and mechanical properties, Inconel 800 is widely used in:

Chemical Processing: Reactors, heat exchangers, and piping systems.

Power Generation: Heat exchangers, superheater tubes, and boiler components.

Heat Treatment: Furnace components, trays, and fixtures.

Oil and Gas: Downhole tubing and piping for corrosive environments.

Petrochemical: Equipment exposed to high temperatures and corrosive gases.

Why Choose Us?

Incoloy 800 strip is a versatile nickel-iron-chromium alloy with excellent high-temperature resistance, oxidation resistance, and corrosion resistance. Its optimized manufacturing process and cost-control measures ensure high-quality production at competitive costs. This material is ideal for demanding applications in chemical processing, power generation, and heat treatment industries, where reliability and performance under extreme conditions are critical.Huaxiao Metal alloy products are good quality, Please contact us for any of your requirements.

Incoloy 800 strip is a nickel-based high-temperature alloy with excellent high-temperature performance, corrosion resistance, and mechanical properties. It is widely used in various industries due to its comprehensive advantages. By optimizing manufacturing processes and controlling costs, Incoloy 800 strip can provide longer service life and better operational stability for equipment in high-temperature and high-corrosion environments. Huaxiao Metal Supplier has all kinds of alloy, the delivery is fast, the service has the customerized solutions.

FAQ

Can you provide samples?

For small parts, we can provide free samples of regular sizes, but the shipping costs must be borne by you. For large samples, we will include it in the order amount. Please confirm with our sales department according to your specific requirements.

What is the difference between Incoloy 825 and Incoloy 800?

Incoloy 825 and Incoloy 800 are both nickel-iron-chromium alloys but differ in composition and performance. Incoloy 825 and Incoloy 800 are both nickel-iron-chromium alloys but differ in composition and performance.

What is the corrosion resistance of this metal material?

Our metal products use special alloy formulas (such as Incoloy 800 maintaining molybdenum and copper elements), which exhibit excellent corrosion resistance in oxidizing/reducing acid (such as sulfuric acid, phosphoric acid) environments.

How long is your delivery time?

It is usually 35 days, but it is also affected by your specific requirements or order quantity.

What is the minimum order quantity?

Our minimum order quantity is 100kg. Larger quantity, lower price.

How do you control product quality?

From raw material selection to packaging for transport, each production step undergoes rigorous testing and evaluation. Only products that pass all tests are approved for export.