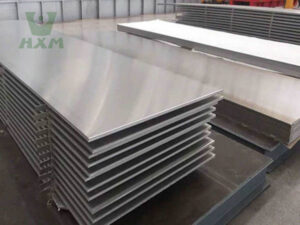

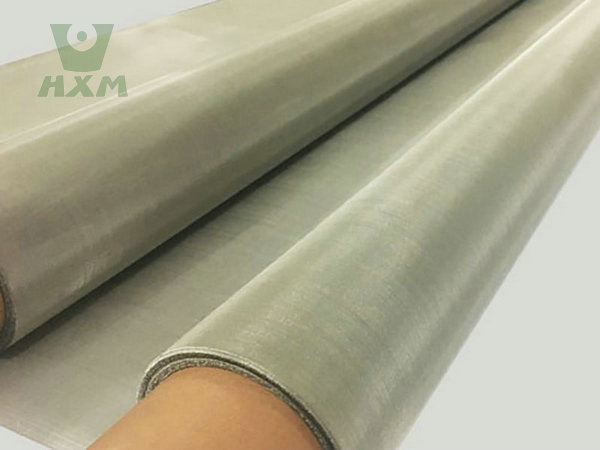

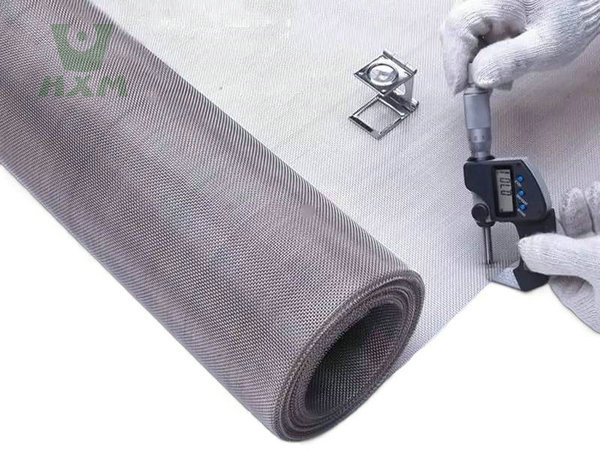

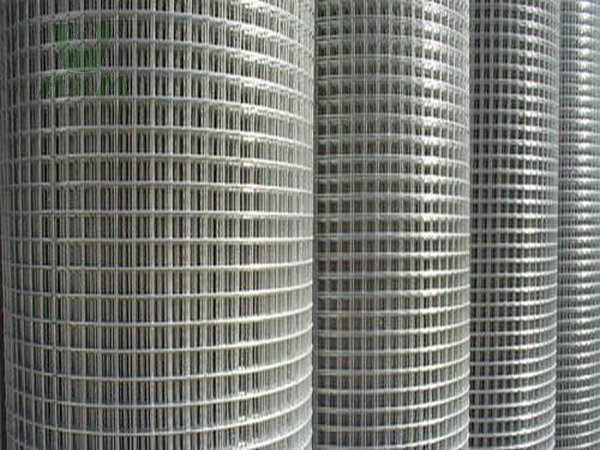

Hastelloy C22 Wire & Hastelloy C22 Mesh, please note that the above table provides a range of standard thicknesses, widths, and lengths for Hastelloy.

- Dimensions:

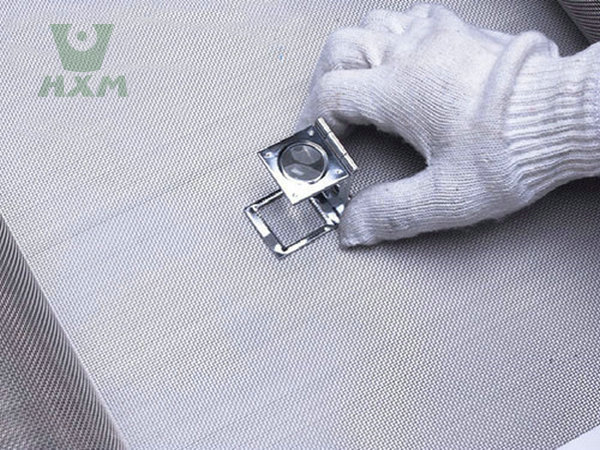

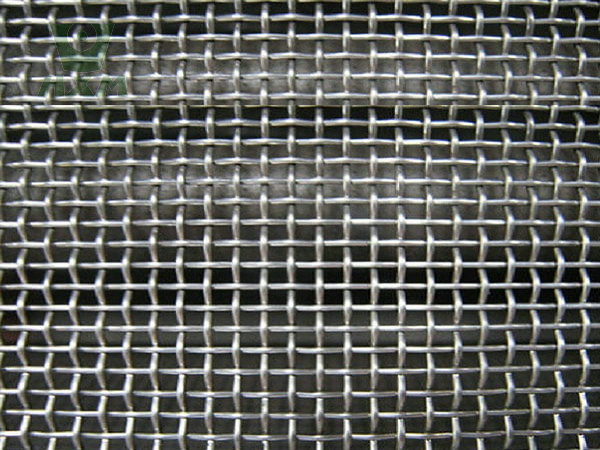

- Mesh : 2-200Mesh

- Diameter: 0.05mm-18mm

- Roll Width: 0.1m-1.5m

- Roll Length: 10-100m

- *Customized size needs to be confirmed with us

- Delivery State: Cold Drawn, Hot Rolled, Forged, Grinding, Centerless Grinding

- Certification: ISO, SGS, BV and so on.

Composition of Hastelloy C22 Wire

Below is the detailed chemical composition of Hastelloy C22 wire mesh, which is a nickel-molybdenum alloy known for its excellent resistance to reducing environments, such as hydrochloric acid and sulfuric acid. Huaxiao Metal Supplier has the many kinds of hastelloy wire and hastelloy mesh, welcome to inquiry.

- The composition ranges may vary slightly depending on the specific manufacturer and production batch.

- Specifications such as wire diameter, length, and surface finish can be customized according to customer requirements.

- Hastelloy C22 wire conforms to standards such as ASTM and ASME, ensuring its quality and performance.

| Element | Composition Range (%) | Specifications |

|---|---|---|

| Nickel (Ni) | Balance or 57-63 | Wire diameter: Various sizes available (e.g., 0.01-10mm) |

| Chromium (Cr) | 19-23 or 20.0-22.5 | Length: Varies (e.g., 2m – 6m or custom lengths) |

| Molybdenum (Mo) | 14-17 or 12.5-14.5 | Surface finish: Bright, polished, or black |

| Tungsten (W) | 2.5-4 | Grade: Hastelloy C22 (UNS N06022) |

| Others (Fe, Co, C, Si, Mn, etc.) | Trace amounts | Standards: ASTM, ASME, etc. |

We have a large amount of high-quality alloy inventory ready for shipment, please request a quote immediately.

Physical Property of Hastelloy C22 Mesh

| Physical Property | Value | Unit |

|---|---|---|

| Density | 8.61 – 8.69 | g/cm³ |

| Melting Point | 1325 – 1370 | °C |

| Specific Heat | 440 | J/kg·K |

| Electrical Resistivity | 1114.0 | μΩ·cm |

| Thermal Conductivity | 10.6 | W/m·K |

| Coefficient of Thermal Expansion | 12.4 – 13.7 (varying with temperature range) | x10^-6/°C |

| Typical Mesh Sizes | Various (e.g., 10, 20, 40, 80, 100, 200 mesh) | – |

Hastelloy C22 mesh combines these physical properties with excellent corrosion resistance, high strength, and good processability. These characteristics make it an ideal material for applications in harsh environments, such as chemical processing, petrochemicals, marine engineering, nuclear energy, and more. Huaxiao Metal Manufacturer provides the various the alloy products and the best solution for customers. Welcome to inquiry and ask for our exports any questions about alloy, we will all slove for you freely. Looking forward to your inquiry and email.

Mechanical Property of Hastelloy C22 Wire

| Mechanical Property | Value | Unit |

|---|---|---|

| Tensile Strength (Ultimate) | 690 – 820 | MPa |

| Yield Strength (0.2% Offset) | 295 – 345 | MPa |

| Elongation at Break | ≥ 40 | % |

| Reduction of Area | ≥ 50 | % |

| Hardness (Rockwell B, Annealed) | 89 – 93 | HRB |

| Shear Strength | Approx. 485 | MPa (estimated based on tensile strength) |

| Modulus of Elasticity | 210 | GPa |

| Poisson’s Ratio | 0.31 | – |

Hastelloy C22 wire combines these mechanical properties with excellent corrosion resistance, making it suitable for a wide range of applications in harsh environments. Its high tensile and yield strengths, combined with good ductility and high resistance to corrosion, make it an ideal material for applications such as chemical processing, petrochemical refining, marine engineering, and nuclear energy. We have a large amount of high-quality alloy inventory ready for shipment, please request a quote immediately. If you have any demand for Hastelloy alloy wire mesh, please contact us by email, special specifications can be customized according to requirements.

Advantages of Hastelloy C22 Wire

- Excellent Corrosion Resistance:

- Hastelloy C22 wire exhibits superior resistance to a wide range of corrosive environments, including strong oxidizing agents, chloride solutions, and high-temperature, high-pressure water.

- Its high molybdenum and chromium content provides exceptional resistance to chloride ion attack, making it one of the few materials that can withstand the corrosion of wet chlorine, hypochlorites, and chlorine dioxide solutions.

- High Temperature Strength and Stability:

- The alloy maintains good strength and ductility at elevated temperatures, making it suitable for applications in high-temperature environments.

- Its high melting point and ability to retain mechanical properties at high temperatures ensure stable performance in demanding conditions.

- Good Weldability:

- Hastelloy C22 wire is easily weldable using various welding methods, such as gas-tungsten arc welding (TIG), gas metal arc welding (MIG), and manual arc welding.

- The alloy has resistance to grain boundary precipitate formation in the weld heat-affected zone, allowing it to maintain corrosion resistance in welded conditions.

- Excellent Mechanical Properties:

- The wire possesses high tensile strength, yield strength, and elongation at break, ensuring it can withstand significant forces and deformations without failing.

- Its modulus of elasticity and Poisson’s ratio contribute to its overall mechanical performance, making it suitable for a range of structural applications.

- Versatile Applications:

- Due to its comprehensive properties, Hastelloy C22 wire is widely used in industries such as chemical processing, petrochemical refining, pulp and paper, environmental protection, and nuclear energy.

- It is particularly suited for components in equipment handling corrosive media, such as reactors, heat exchangers, pumps, valves, and piping systems.

- Good Processability:

- Hastelloy C22 wire can be processed through conventional hot and cold working methods, such as forging, rolling, drawing, and stamping, to form various shapes and sizes of components.

- However, care must be taken to control the temperature and speed during processing to avoid overheating and work hardening.

Manufacturing Process of Hastelloy C22 Wire

The manufacturing process of Hastelloy C22 wire involves several crucial steps to ensure the final product meets the rigorous standards required for its intended applications. The manufacturing process of Hastelloy C22 wire is a complex and precise series of steps that ensures the final product possesses the exceptional corrosion resistance, high-temperature strength, and other critical properties required for its intended applications. Huaxiao Metal Supplier is professional and experienced in producing alloy products in China. Welcome to consult any question about alloy and contact us any time when you are free, and our company of stafff will reply you in 24 hours.

- Raw Material Preparation:

- The raw materials, consisting primarily of nickel, chromium, molybdenum, tungsten, and other alloying elements, are carefully selected and prepared.

- The proportions of these elements are precisely controlled to achieve the desired chemical composition and properties of Hastelloy C22.

- Melting and Alloying:

- The raw materials are melted in a vacuum induction melting (VIM) furnace or an inert gas-protected atmosphere to prevent contamination.

- The melting temperature is strictly controlled to ensure uniform mixing of the alloy elements and to eliminate any porosity or inclusions.

- Optionally, the molten alloy may undergo electroslag remelting (ESR) to further refine its microstructure and improve mechanical properties.

- Casting and Ingot Formation:

- After melting, the alloy is cast into ingots, which are then allowed to cool slowly to minimize internal stresses and defects.

- The ingots are inspected for quality, including checks for composition, microstructure, and mechanical properties.

- Hot Working:

- The ingots are then subjected to hot working processes such as forging, hot rolling, or extrusion to shape the material into wires or other desired forms.

- These processes are performed at temperatures within the alloy’s hot working range, typically between 1150°C and 1230°C, to facilitate deformation and to maintain material properties.

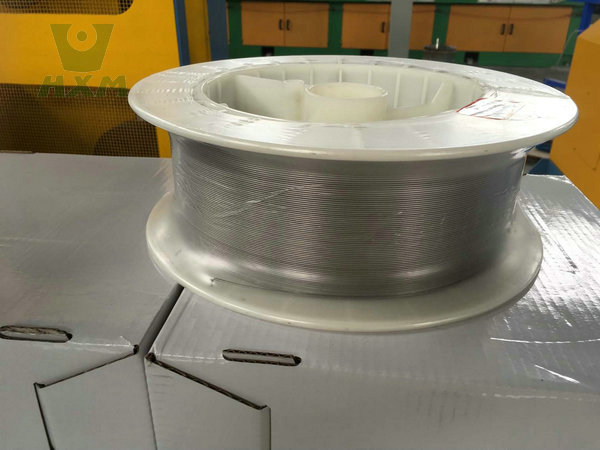

- Cold Working and Drawing:

- Following hot working, the material may undergo cold working processes such as cold drawing or cold rolling to achieve the final wire gauge and dimensions.

- Cold working increases the strength and hardness of the wire but may also require annealing to restore ductility and reduce internal stresses.

- Heat Treatment:

- Heat treatment, including solution annealing, quenching, and aging, is performed to optimize the mechanical properties and microstructure of the Hastelloy C22 wire.

- These processes are carefully controlled to avoid detrimental effects on corrosion resistance and other critical properties.

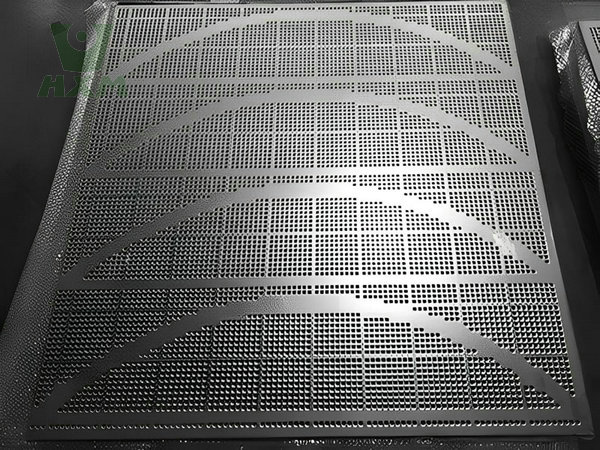

- Surface Finishing:

- The surface of the wire may be polished or otherwise finished to meet specific application requirements.

- This step ensures a smooth, clean surface that enhances corrosion resistance and appearance.

What is Hastelloy C22 Wire?

Hastelloy C22 Mesh is a nickel-chromium-molybdenum-based alloy renowned for its exceptional corrosion resistance. It demonstrates high tolerance to a wide range of aggressive media, including strong acids and chloride solutions, making it suitable for harsh environments. The alloy offers high mechanical strength and maintains its properties at elevated temperatures. Huaxiao Metal Supplier is professional and experienced in alloy producing factory, our company provides the personalized services and welcome to inquiry about the lastest price. As the distributer, our compoany has the most reasoanable policies for you buying the alloy products.

Applications of Hastelloy C22 Wire

Hastelloy C22 wire’s unique combination of corrosion resistance, high mechanical strength, and good fabricability makes it a versatile material for demanding applications across multiple industries. It finds extensive applications across various industries due to its exceptional properties. Welcome to ask for the lastest price.

Chemical Processing Industry: It is widely used in manufacturing corrosion-resistant equipment such as reactors, heat exchangers, piping, and valves, which are exposed to harsh chemicals.

Petrochemical Industry: Due to its outstanding resistance to hydrogen sulfide corrosion, Hastelloy C22 wire is ideal for applications like wellbore casings and other critical components.

Marine Engineering: It is employed in the fabrication of subsea pipelines, valves, and other equipment that must withstand seawater corrosion and stress corrosion cracking in marine environments.

Nuclear Industry: Hastelloy C22 wire is suitable for components like fuel rod cladding in nuclear reactors, where it can maintain performance under extreme conditions such as high-temperature, high-pressure water corrosion.

Energy Sector: It is used in high-temperature components of solar and wind energy equipment, enduring high-temperature corrosion and oxidation.

Pharmaceutical and Pharmaceutical Manufacturing: In the production of pharmaceuticals and fertilizers, Hastelloy C22 wire ensures the durability of reactors, pipelines, and heat exchangers handling corrosive media.

Environmental Protection and Water Treatment: Its corrosion resistance makes it ideal for equipment in wastewater treatment plants and other environmental protection applications.

Why Choose Us?

Hastelloy C22 wire offers a unique combination of corrosion resistance, high-temperature strength, good weldability, excellent mechanical properties, versatile applications, and good processability. These advantages make it an ideal material for demanding applications in harsh environments.

Huaxiao Metal Manufacturer provides the hastelloy plate, and other shapes, such as tubes, wires, strip, coil, bar etc. Alloys of various shapes and materials are available, welcome to choose and consult the price.

As a leading stainless steel supplier, our company stands out for the following reasons:

Unmatched Industry Expertise & Scale

With decades of experience and state-of-the-art production facilities, we deliver large-scale orders efficiently while maintaining stringent quality control. Our vertical integration ensures competitive pricing and reliable supply.Premium Quality & Certifications

All products meet international standards (ASTM, ISO, EN) and undergo rigorous testing. We use advanced manufacturing technologies and eco-friendly processes to guarantee durability, corrosion resistance, and precision.Customized Solutions

From standard grades (304, 316L) to specialized alloys, we offer tailored specifications for industries like construction, automotive, and medical. Our engineering team provides technical support to optimize material selection.Global Reach & Agile Delivery

With a robust logistics network, we ensure timely delivery to clients worldwide. Our customer-centric approach includes flexible MOQs, real-time order tracking, and dedicated after-sales service to build long-term partnerships.

Our products are guaranteed in quality, and our professional team can provide technical support and consulting services. If you need more information or have any questions, please free to contact our customer service team.

FAQ

Can you provide samples?

For small parts, we can provide free samples of regular sizes, but the shipping costs must be borne by you. For large samples, we will include it in the order amount. Please confirm with our sales department according to your specific requirements.

What is the functions of Hastelloy C22?

Hastelloy C22 is a nickel-based alloy with exceptional corrosion resistance in oxidizing/reducing acids (e.g., sulfuric, hydrochloric). It resists pitting, crevice corrosion, and stress cracking, ideal for chemical processing, pollution control, and marine environments. Suitable for high-temperature and harsh chemical applications.

Do you support customized sizes?

We provide various forms such as plates, rods, and pipes, with a minimum processing accuracy of ± 0.02mm. The customization cycle is usually 7-15 working days, and specific details need to be confirmed with the sales team.

How long is your delivery time?

It is usually 35 days, but it is also affected by your specific requirements or order quantity.

What is the minimum order quantity?

Our minimum order quantity is 100kg. Larger quantity, lower price.

How do you control product quality?

From raw material selection to packaging for transport, each production step undergoes rigorous testing and evaluation. Only products that pass all tests are approved for export.