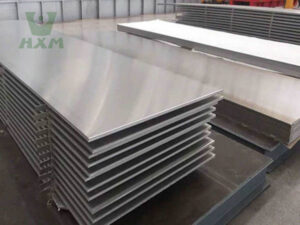

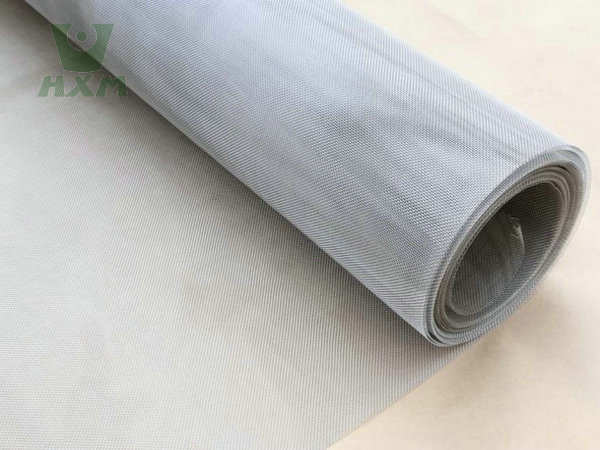

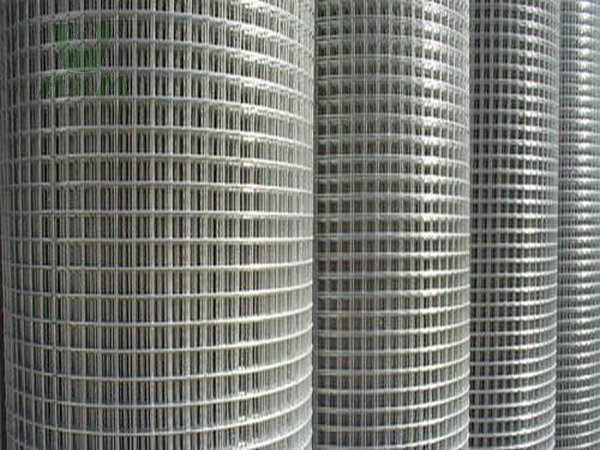

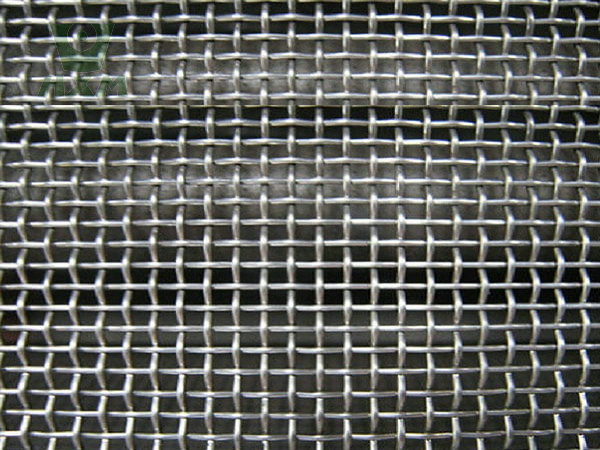

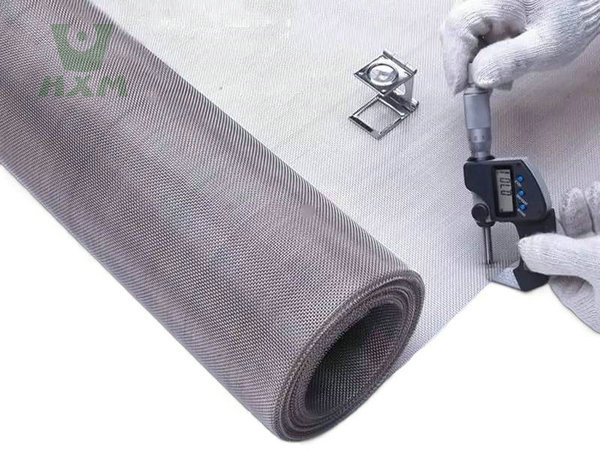

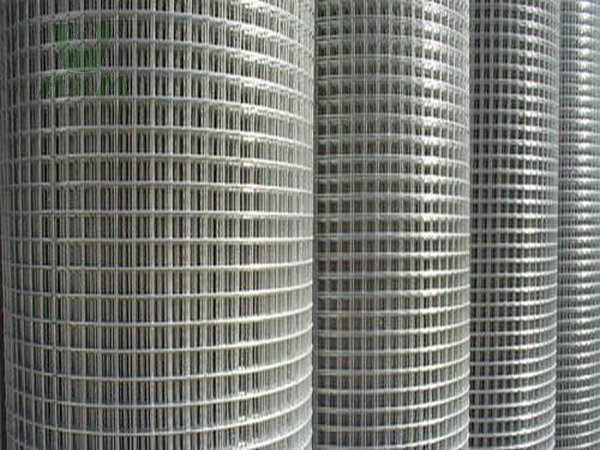

Hastelloy B2 Wire & Hastelloy B2 Mesh, please note that the above table, Huaxaio Metal Manufacturer provides a range of standard diameter, widths, and lengths for Hastelloy Alloy Mesh.

- Dimensions:

- Diameter(D) : 0.05mm-20mmm

- Standards:ASTM B335, ASTM B472, ASME SB335

- *Customized size needs to be confirmed with us

- Delivery State: Cold Drawn, Hot Rolled, Forged, Grinding, Centerless Grinding

- Finish: Bright, Polishing, Mirror, Hairline, Pickled, Peeled, Black

- Certification: ISO, SGS, BV and so on.

Composition of Hastelloy B2 Wire

Below is the detailed chemical composition of Hastelloy B2 (UNS N10665) wire mesh, which is a nickel-molybdenum alloy known for its excellent resistance to reducing environments, such as hydrochloric acid and sulfuric acid. Huaxiao Metal Supplier has the many kinds of hastelloy wire and hastelloy mesh, welcome to inquiry.

| Element | Composition (%) | Purpose/Effect |

|---|---|---|

| Nickel (Ni) | 65–70 | Provides the base matrix, offering high strength and corrosion resistance. |

| Molybdenum (Mo) | 26–30 | Enhances resistance to reducing environments, such as hydrochloric and sulfuric acids. |

| Iron (Fe) | 2.0 max | Acts as a stabilizer and improves mechanical properties. |

| Chromium (Cr) | 1.0 max | Provides minimal oxidation resistance but is kept low to avoid carbide formation. |

| Cobalt (Co) | 1.0 max | Enhances high-temperature strength and creep resistance. |

| Manganese (Mn) | 1.0 max | Acts as a deoxidizer and improves hot workability. |

| Silicon (Si) | 0.1 max | Improves oxidation resistance and fluidity during casting. |

| Carbon (C) | 0.02 max | Kept low to minimize carbide formation and maintain weldability. |

| Sulfur (S) | 0.01 max | Minimized to avoid hot cracking during welding. |

| Phosphorus (P) | 0.04 max | Minimized to prevent embrittlement. |

We have a large amount of high-quality alloy inventory ready for shipment, please request a quote immediately.

Physical Property of Hastelloy B2 Mesh

| Property | Description/Value |

|---|---|

| Material | Hastelloy B2 Mesh |

| Density | ~8.47 g/cm³ (approximate) |

| Melting Point | 1325-1370 °C (2417-2498 °F) |

| Thermal Conductivity | ~11.0-17.0 W/m·K (varies with temperature) |

| Coefficient of Thermal Expansion | ~12.3 µm/m·°C (at 20-100 °C) |

| Electrical Resistivity | ~1.30 µΩ·m (at 20 °C) |

| Young’s Modulus | ~200 GPa (approximate) |

| Poisson’s Ratio | ~0.31 (approximate) |

| Tensile Strength | Varies with heat treatment and condition (e.g., ultimate tensile strength can be in the range of 690-1030 MPa) |

| Yield Strength | Varies with heat treatment and condition (e.g., 0.2% offset yield strength can be in the range of 310-620 MPa) |

| Hardness | Varies with heat treatment and condition (e.g., Brinell hardness can be in the range of 100-220 HBW) |

| Magnetic Properties | Generally non-magnetic, but may exhibit some magnetism due to cold working or heat treatment |

Hastelloy B2 Wire make it an ideal material for applications in harsh environments, such as those in the chemical, petrochemical, marine, and nuclear industries. Its high melting point, corrosion resistance, and dimensional stability make it suitable for a wide range of applications where high performance and reliability are required. Huaxiao Metal Manufacturer provides the various the alloy products and the best solution for customers. Welcome to inquiry and ask for our exports any questions about alloy, we will all slove to you freely.

Mechanical Property of Hastelloy B2 Wire

| Property | Description/Value |

|---|---|

| Material | Hastelloy B2 Wire |

| Tensile Strength (Ultimate) | Varies with condition and diameter, typically 690-1030 MPa (approx.) |

| Yield Strength (0.2% Offset) | Varies with condition and diameter, typically 310-620 MPa (approx.) |

| Elongation | Varies with condition and diameter, typically 15%-40% (approx.) |

| Reduction of Area | Varies with condition and diameter, typically 30%-60% (approx.) |

| Hardness (Brinell) | Varies with condition and diameter, typically 100-220 HBW (approx.) |

| Hardness (Rockwell B) | Varies with condition and diameter, can be determined by conversion from Brinell hardness or direct testing |

| Modulus of Elasticity (Young’s Modulus) | Approximately 200 GPa |

| Poisson’s Ratio | Approximately 0.31 |

| Fatigue Strength | Varies with stress range, number of cycles, and condition; typically lower than tensile strength |

| Creep Strength | Varies with temperature, stress level, and time; typically decreases as temperature increases |

| Impact Strength | Varies with temperature and condition; generally good impact resistance at room temperature |

We have a large amount of high-quality alloy inventory ready for shipment, please request a quote immediately.

Advantages of Hastelloy B2 Wire

- Exceptional Corrosion Resistance:

- Hastelloy B2 Wire demonstrates outstanding resistance to a wide range of corrosive environments.

- It is particularly resistant to reducing acids, chloride-containing solutions, and hydrogen fluoride.

- This makes it suitable for applications where corrosion is a significant concern.

- High-Temperature Stability:

- The alloy maintains good mechanical properties and corrosion resistance at elevated temperatures, up to around 1000°C (1832°F).

- This makes it ideal for use in high-temperature environments, such as those found in gas processing equipment and nuclear industries.

- Good Weldability:

- Hastelloy B2 Wire can be welded using various techniques, such as TIG and MIG welding.

- Proper welding practices and post-weld heat treatment can minimize welding-related issues, ensuring the integrity of the welded joints.

- Excellent Mechanical Properties:

- The alloy offers high tensile strength, yield strength, and ductility.

- These properties ensure that it can withstand the stresses and loads encountered in various industrial applications.

- Resistance to Stress Corrosion Cracking:

- Due to its low carbon content, Hastelloy B2 Wire is resistant to stress corrosion cracking.

- This form of corrosion can lead to sudden failure under stress, so the alloy’s resistance to it is a significant advantage.

- Good Fabrication Characteristics:

- The alloy can be easily formed, machined, and fabricated into various shapes and sizes.

- This versatility makes it suitable for a wide range of manufacturing processes and applications.

- Wide Range of Applications:

- Hastelloy B2 Wire is used in various industries, including chemical processing, petrochemical, pharmaceutical, pulp and paper, nuclear, aerospace, and high-temperature gas processing equipment.

- Its versatility allows it to meet the demanding requirements of these diverse applications.

- Long Service Life:

- The combination of corrosion resistance, high-temperature stability, good mechanical properties, and wide range of applications results in a long service life for Hastelloy B2 Wire.

- This reduces the need for frequent replacements and maintenance, lowering overall costs.

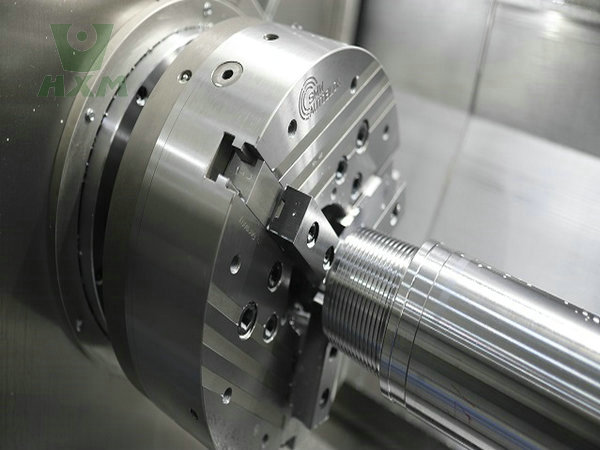

Manufacturing Process of Hastelloy B2 Wire

The manufacturing process of Hastelloy B2 wire involves several crucial steps to ensure the final product meets the rigorous standards required for its intended applications. Huaxiao Metal Supplier is professional and experienced in producing alloy products in China. Welcome to consult any question about alloy and contact us any time.

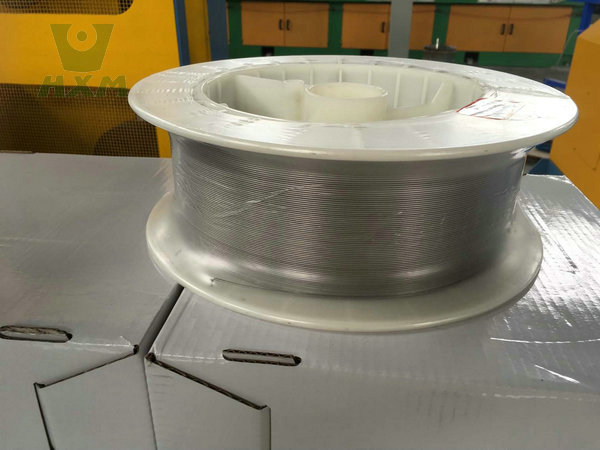

Raw Material Preparation

- Alloy Composition: Hastelloy B2 wire is primarily composed of nickel (Ni), molybdenum (Mo), and other trace elements such as iron (Fe), carbon (C), silicon (Si), manganese (Mn), and copper (Cu). The typical composition ranges are approximately 60% to 70% Ni, 28% to 34% Mo, with the remainder being other elements.

- Material Selection: High-quality raw materials are selected to ensure the purity and composition of the final alloy. These materials undergo rigorous testing to confirm their compliance with specified standards.

Melting and Casting

- Melting Process: The selected raw materials are melted in a vacuum induction melting furnace to ensure a homogeneous alloy composition and to minimize contamination.

- Casting: The molten alloy is then cast into ingots, which are subsequently cooled and prepared for further processing.

Hot and Cold Working

- Hot Rolling: The ingots are heated to an elevated temperature and then hot-rolled into a wire of the desired diameter. This process improves the ductility and workability of the alloy.

- Cold Drawing: After hot rolling, the wire undergoes cold drawing to achieve the final dimensions and improve its mechanical properties. Cold drawing also enhances the wire’s surface finish and dimensional accuracy.

Heat Treatment

- Solution Treatment: The wire is subjected to a solution treatment at a specific temperature, typically around 1065°C (1950°F), followed by rapid cooling. This process adjusts the alloy’s grain structure and phase composition, enhancing its corrosion resistance and mechanical properties.

- Aging Treatment: In some cases, an aging treatment may be applied to further optimize the alloy’s properties.

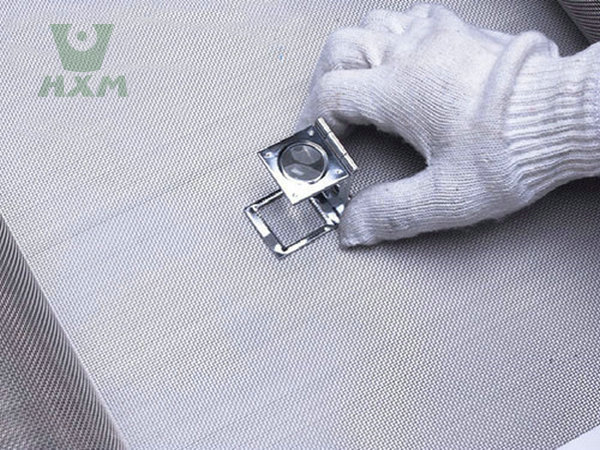

Surface Treatment and Inspection

- Pickling and Passivation: The wire may undergo pickling and passivation treatments to remove surface oxides and improve its corrosion resistance.

- Inspection: The wire is inspected at various stages of the manufacturing process to ensure compliance with specified standards. This includes chemical composition analysis, mechanical property testing, and non-destructive testing.

What is Hastelloy B2 Wire?

Hastelloy B2 wire is a type of nickel-based alloy wire that is renowned for its exceptional corrosion resistance, high temperature stability, and oxidation resistance. Its unique properties make it suitable for various demanding applications in industries such as chemical processing, petrochemicals, nuclear energy, aerospace, and more. Huaxiao Metal Supplier is professional in alloy producing factory, our company provides the personalized services and welcome to inquiry about the lastest price. As the distributer, our compoany has the most reasoanable policies for you buying the alloy products.

Applications of Hastelloy B2 Wire

Hastelloy B2 wire is primarily composed of nickel, with molybdenum being the second most significant alloying element. The typical composition ranges from approximately 60% to 70% nickel and 28% to 34% molybdenum, with smaller amounts of iron, carbon, silicon, manganese, and copper. The high molybdenum content significantly enhances the alloy’s corrosion resistance, particularly in acidic environments. Welcome to ask for the lastest price.

- Chemical Industry: It is used to manufacture reactors, pipelines, and containers, particularly in environments with strong acid corrosion.

- Petrochemical Industry: The alloy is commonly used in high-temperature and corrosive environments, such as heat exchangers, reactors, and pipelines in refineries.

- Nuclear Industry: Hastelloy B2 wire is used in cooling systems of nuclear reactors due to its high temperature and corrosion resistance.

- Aerospace Industry: It is applied in components of aerospace vehicles and aircraft engines, especially in high-temperature and high-corrosion environments.

- High-Temperature Gas Processing Equipment: The alloy is used as corrosion-resistant material in equipment such as combustion furnaces and exhaust treatment systems.

Why Choose the Hstelloy B2 Alloy?

- Exceptional Corrosion Resistance: Withstands aggressive reducing acids (e.g., sulfuric, hydrochloric) at high temps, ideal for chemical/petrochemical industries.

- High-Temperature Stability: Maintains mechanical integrity up to 1,000°C, ensuring reliability in extreme environments.

- Superior Fabricability: Easily machined, welded, and formed, reducing production costs and lead times.

- Customized Solutions: As a leading Chinese manufacturer, we offer tailored specifications, strict quality control (ISO-certified), and global export expertise.

Our products are guaranteed in quality, and our professional team can provide technical support and consulting services. If you need more information or have any questions, please free to contact our customer service team.Each Hastelloy grade offers unique chemical, physical, and mechanical properties, making them suitable for specific applications. Production costs and processing flows vary based on alloy composition, purity, and processing requirements. Understanding these differences is crucial for selecting the appropriate Hastelloy grade for a given application. Huaxiao Metal Manufacturer provides the hastelloy plate, and other shapes, such as tubes, wires, strip, coil, bar etc. Alloys of various shapes and materials are available, welcome to choose and consult the price.

FAQ

Can you provide samples?

For small parts, we can provide free samples of regular sizes, but the shipping costs must be borne by you. For large samples, we will include it in the order amount. Please confirm with our sales department according to your specific requirements.

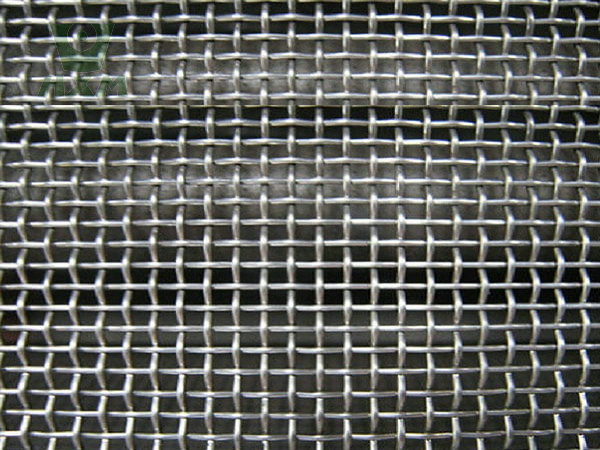

What is the welding performance of Hastelloy B2 Mesh?

Hastelloy B2 Mesh exhibits good weldability but requires careful control to avoid hot cracking and weld metal embrittlement. Use low heat input, slow cooling, and ERNiMo-7 filler. Post-weld annealing (1150°C) restores corrosion resistance. Suitable for TIG/MIG welding.

Do you support customized sizes?

We provide various forms such as plates, rods, and pipes, with a minimum processing accuracy of ± 0.02mm. The customization cycle is usually 7-15 working days, and specific details need to be confirmed with the sales team.

How long is your delivery time?

It is usually 35 days, but it is also affected by your specific requirements or order quantity.

What is the minimum order quantity?

Our minimum order quantity is 100kg. Larger quantity, lower price.

How do you control product quality?

From raw material selection to packaging for transport, each production step undergoes rigorous testing and evaluation. Only products that pass all tests are approved for export.