Hastelloy Alloy Wire & Mesh, please note that the above table provides a range of standard thicknesses, widths, and lengths for Hastelloy.

- Dimensions:

- Diameter: 0.05mm – 15mm

- Roll Size: 1x30m/roll 1.22x30m/roll 1.5x30m/roll….

- *Customized size needs to be confirmed with us

- Classification: Spring wire, welding wire, hydrogen wire, bright wire, half-soft wire, soft wire, cold-forging wire, etc.

- Grades: X, B, B-2, B-3, C, C-4, C-22, C-22HS, C-276, C-20000, G-3, G-30, G-35, N, S.

Hastelloy Alloy Wire Size And Specifications

Huaxiao Metal Supplier provides all sizes of hastelloy alloy plate for sale. Hastelloy Alloy Wire is available in various specifications to suit different applications. Commonly, it comes in diameters ranging from a fraction of a millimeter to several millimeters, and its length can vary from meters to tens of meters. For instance, some Hastelloy Alloy Wire products are offered in diameters as small as 0.25mm or as large as Φ5.5-25, with lengths up to 100m or in the form of coils. Custom sizes are also available upon request. Welcome to inquire and ask for the lastest price.

| Specification | Details |

|---|---|

| Material Shape | Wire (Round, Flat, or custom shapes upon request) |

| Diameter (Round Wire) | 0.05mm – 12.00mm (Common sizes: 0.1mm, 0.25mm, 0.5mm, 1.0mm, 2.0mm, etc.) |

| Width (Flat Wire) | 1.0mm – 50.0mm (Customizable based on requirements) |

| Thickness (Flat Wire) | 0.05mm – 5.00mm (Depends on width and application needs) |

| Length | Coiled (Standard lengths: 100m, 500m, 1000m per coil) or cut-to-length as specified |

| Tolerances | Diameter: ±0.005mm (for fine wires) to ±0.1mm (for larger diameters) |

| Width & Thickness: ±0.02mm to ±0.1mm (Depends on material and size) | |

| Surface Finish | Bright, Matte, or Polished (as per customer’s requirement) |

| Packaging | Coiled in plastic spools, wooden reels, or cardboard boxes (for protection during transport) |

You can click this button to fill in the basic information of this form. If you have any questions, you can describe them in detail. Our experts will provide you with customized solutions. As a leading metal trading wholesaler in China, we will provide the best metals and services to our customers.

Hastelloy Alloy Wire Basic Information Sheet

Hastelloy steel wire has many kinds of materials and shapes in China. Huaxiao Metal Manufacturer also provides other shapes of Hastelloy plate, such as bar, coil, strip, tube&pipe, sheet&plate. The price is affordable and suitable.

| Specification/Alloy Grade | Hastelloy B-2 (UNS N10665) | Hastelloy C-22 (UNS N06022) | Hastelloy C-276 (UNS N10276) | Hastelloy X |

|---|---|---|---|---|

| Wire Diameter | 0.25 mm to 10 mm (various sizes available) | 0.1 mm to 8 mm (customizable) | 0.5 mm to 6 mm (standard) | As per customer requirements |

| Forms Available | Round wire, Coil | Round wire, Coil, Sheet, Plate | Round wire, Coil, Bar | Round wire, Rod, Bar |

| Chemical Composition | Ni: 68-71%, Mo: 26-30%, Fe: ≤2%, Cr: ≤1% | Ni: ≥57%, Cr: 20-23%, Mo: 13-16%, W: 2.5-3.5% | Ni: ≥52%, Cr: 14.5-18%, Mo: 15-17%, Fe: ≤4% | Ni: 20.5-23%, Cr: 17-20%, Fe: 8-10%, Mo: 0.2-1% |

| Density | ≈9.2 g/cm³ | ≈8.78 g/cm³ | ≈8.44 g/cm³ | ≈8.28 g/cm³ |

| Tensile Strength | ≥690 MPa (at room temperature) | ≥620 MPa (typical) | ≥617 MPa (min) | ≥690 MPa (after solution treatment) |

| Yield Strength | ≥240 MPa (0.2% offset) | ≥220 MPa (0.2% offset) | ≥240 MPa (0.2% offset) | ≥275 MPa (at room temperature) |

| Elongation | ≥40% | ≥40% | ≥40% | ≥30% (at room temperature) |

| Hardness | HB ≤220 | HB ≤248 | RB ≤100 (max) | HBS ≥241 |

| Melting Point | 1330-1380 °C | 1300-1400 °C | 1325-1370 °C | 1295-1381 °C |

| Corrosion Resistance | Excellent in reducing environments, resistant to hydrochloric acid | Excellent in oxidizing and reducing environments, resistant to chloride-induced corrosion | Excellent resistance to a wide range of corrosive media | Good resistance to high temperature, high pressure, strong acids, and strong bases |

| Standard | ASTM B335, ASME SB335 | ASTM B574, ASME SB574 | ASTM B575, ASME SB575 | ASTM B572, ASTM B435, ASTM B622 |

What are the Benefits?

Hastelloy alloy wire offers significant benefits, including exceptional durability and corrosion resistance in harsh environments, versatility in a wide range of applications, cost-effectiveness due to reduced maintenance and long-term durability, improved safety and reliability, ease of processing and fabrication, and compliance with industry standards. These benefits make it an ideal choice for critical components in various industries. Welcome to Huaxiao Metal Manufacturer to requset the price, trust you can be satisfied in the alloy products. You can click this button to fill in the information of this form. If you have any questions, you can describe them. Our experts will provide you with customized solutions.

Hastelloy Alloy Wire Applications and Uses

Huaxiao Metal Supplier provides all kinds of alloy wire and mesh in the world. In the chemical and petrochemical industries, it is widely used in reactors, heat exchangers, and piping systems due to its ability to withstand harsh corrosive environments. Within the oil and gas sector, Hastelloy alloy wire is employed in downhole components and refinery equipment, where it demonstrates resilience against high temperatures and pressure.Moreover, its high-temperature strength and resistance to stress-corrosion cracking make it ideal for aerospace applications, such as turbine blades and jet engine parts. In the marine industry, Hastelloy alloy wire is utilized in seawater systems and desalination plants, ensuring durability and corrosion resistance in high-chloride environments.

Additionally, it finds application in nuclear reactors and waste treatment facilities, where its resistance to radiation and high-temperature corrosion is crucial. Welcome to inquiry.

Hastelloy Alloy Wire Advantages

Hastelloy alloy wire stands as a premier choice for demanding industrial applications due to its exceptional combination of properties that outperform conventional materials. This nickel-based superalloy exhibits unparalleled corrosion resistance in aggressive environments, including strong acids, chlorides, and high-temperature oxidizing conditions that would rapidly degrade ordinary stainless steels. The material’s unique chemical composition, typically featuring high molybdenum and chromium content, provides outstanding protection against pitting, crevice corrosion, and stress corrosion cracking. Beyond its corrosion resistance, Hastelloy wire maintains impressive mechanical strength at elevated temperatures, making it suitable for furnace components and chemical processing equipment.

Exceptional Corrosion Resistance: Hastelloy steel wire exhibits remarkable resistance to a wide range of corrosive media, including acids, bases, and salts. This makes it suitable for use in harsh environments where corrosion is a significant concern.

High-Temperature Stability: The metal maintains its strength and corrosion resistance at elevated temperatures, making it ideal for applications involving high-temperature processes such as thermal treatment, welding, and annealing.

Stress-Corrosion Cracking Resistance: Hastelloy metal wire is highly resistant to stress-corrosion cracking, which is a form of corrosion that can lead to sudden failure of materials under stress. This property is particularly important in applications where materials are subjected to both tensile stress and corrosive environments.

You can click this button to fill in the basic information of this form. If you have any questions, you can describe them in detail. Our experts will provide you with customized solutions. As a leading metal trading wholesaler in China, we will provide the best metals and services to our customers.

Good Mechanical Properties: The steel offers good mechanical properties, including high tensile strength, yield strength, and elongation. These properties ensure that Hastelloy alloy wire can withstand high loads and deformations without failing.

Versatility: Hastelloy steel wire can be processed into various forms, such as round wire, coil, bar, and sheet, making it versatile for different applications. Additionally, it can be welded, brazed, and machined using standard techniques.

Compliance with Standards: Hastelloy alloy wire adheres to ASME and ASTM specifications, ensuring its reliability and performance across diverse applications. This compliance with industry standards provides users with peace of mind regarding the quality and safety of the material.

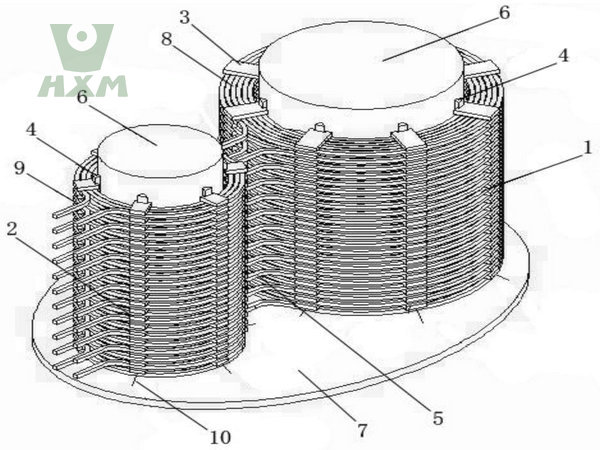

Alloy Factory

The alloy factory is a specialized facility engaged in the production of various types of alloy materials, including Hastelloy alloy wire and other high-performance alloys. As a wholesale price supplier to customers, the alloy factory provides a comprehensive range of alloy products at competitive prices.Our factory utilizes advanced manufacturing technology and strict quality control measures to ensure the consistent quality and reliability of our alloy products. We offer a wide selection of alloys tailored to meet the specific needs of different industries, such as aerospace, marine engineering, chemical processing, and oil refining. As a wholesale price supplier, we are committed to providing our customers with the best possible value.

We offer volume discounts and flexible pricing options to accommodate various purchasing requirements. Our dedicated sales team is always available to assist you with product inquiries, customization requests, and order processing to ensure a seamless purchasing experience. Huaxiao Metal Supplier provides professional services and reasonable prices, offering customers the best quality products. Welcome to reqiure, and ask to the price. You can click the button and get the quote quickly.

You ask, we answer

We can provide small hastelloy alloy sheet samples for you to check the quality. The sample is free, you only need to pay the shipping cost.

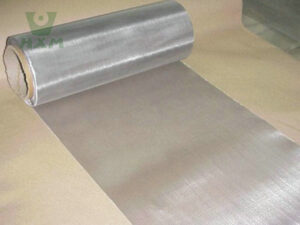

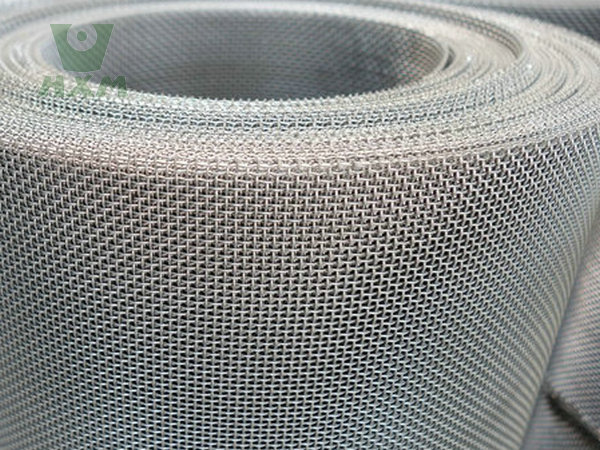

Hastelloy wire mesh, renowned for its exceptional corrosion resistance, is primarily sourced from manufacturers in China’s Hebei Anping region, a global hub for wire mesh production. Suppliers like Anping Leshang offer customized meshes woven from nickel-based Hastelloy alloys (C-276, C-22), designed for harsh environments in industries such as chemical processing and energy.

Hastelloy C276 alloy is a nickel-based superalloy with exceptional corrosion resistance, high temperature strength, and durability, making it ideal for a wide range of industrial applications.

Hastelloy B3 alloy stands out due to its exceptional corrosion resistance, enhanced thermal stability, improved weldability, superior physical properties, and versatile applications. These advantages make it a preferred material for various demanding industrial applications.