Hastelloy Alloy Manufacturer in China

Hastelloy Metal Alloy Size and Specifications

At Huaxiao Metal, we pride ourselves on offering the highest-quality Hastelloy alloys to meet the specific needs of our customers. Our comprehensive range of corrosion-resistant and heat-resistant grades ensures that oue company has the good solution for your application. Welcome to inquire and ask the lastest price online or send email by website.

Supply Material: B, B-2, B-3, C, C-4, C-22, C-22HS, C-276, C-20000, G-3, G-30, G-35, N, S.

| Alloy Grade | Product Form | Size Range | Remarks |

|---|---|---|---|

| Hastelloy C-276 | Sheet/Plate | Thickness: 0.5–80 mm, Width: 1000–2000 mm, Length: 1000–6000 mm | Custom sizes available upon request |

| Bar/Rod | Diameter: 6–500 mm, Length: 0.5–6 m | Surface finishes include peeled, turned, or as-rolled (black surface) | |

| Pipe/Tube | Outer Diameter: 6–530 mm, Wall Thickness: 0.5–50 mm, Length: 1–6 m | Both seamless and welded tubes available | |

| Forgings | Custom-made according to customer drawings | Various shapes and sizes possible | |

| Hastelloy C-22 | Sheet/Plate | Thickness: 0.5–80 mm, Width: 1000–2000 mm, Length: 1000–6000 mm | Complies with ASTM B575/ASME SB-575 standards |

| Bar/Rod | Diameter: 6–500 mm, Length: 0.5–6 m | Includes turned bars, forged bars, etc. | |

| Pipe/Tube | Outer Diameter: 6–530 mm, Wall Thickness: 0.5–50 mm, Length: 1–6 m | Complies with ASTM B622/ASME SB-622 standards | |

| Forgings, Flanges, etc. | Manufactured as per customer requirements | Complex shapes and custom fittings available | |

| Hastelloy B-3 | Sheet/Plate | Thickness: 0.8–50 mm, Width: 1000–2000 mm, Length: 1000–6000 mm | Suitable for highly corrosive environments |

| Bar/Rod | Diameter: 10–200 mm, Length: 1–6 m | Available in annealed or solution-treated conditions | |

| Pipe/Tube | Outer Diameter: 6–150 mm, Wall Thickness: 1–20 mm, Length: 1–6 m | Ideal for manufacturing corrosion-resistant pipelines and equipment | |

| Forgings, Welding Consumables, etc. | Manufactured as per customer requirements | Various specifications of forgings and welding materials available |

Supply Shapes:plate, bar, coil, strip, tube, wires, mesh, sheet, pipes.

Hastelloy Chemical Composition

Hastelloy alloys are a versatile and highly corrosion-resistant series of nickel-based alloys produced by Haynes International. Their composition varies depending on the specific alloy type, but they generally contain nickel, chromium, molybdenum, and other alloying elements. For pricing and purchasing information, it is recommended to contact the supplier directly.

| Nickel (Ni) | Molybdenum (Mo) | Iron (Fe) | Chromium (Cr) | Cobalt (Co) | Tungsten (W) | Manganese (Mn) | Silicon (Si) | Carbon (C) | Phosphorus (P) | Sulfur (S) | Vanadium (V) | |

| Hastelloy B3 | Balance | 28.5 – 30.5% | 1.0– 3.0% | 1.0 – 3.0% | Up to 3.0 % | 2.5 – 3.5% | Up to 3.0 % | Up to 0.10% | Up to 0.01 % | Up to 0.04 % | Up to 0.03% | Up to 0.20% |

| Hastelloy C276 | 57.0–63.0% (Balance) | 15.0–17.0% | 4.0–7.0% | 14.5–16.5% | Up to 2.5% | Up to 4.0% | Up to 1.0% | Up to 0.08% | Up to 0.01% | Up to 0.04% | Up to 0.03% | Up to 0.35% |

| Hastelloy C22 | Balance | 8.0-10.0% | 17-20% | 20.5-23% | 0.5-2.5% | 0.2-1% | Up to 1.0% | Up to 1.0% | 0.05-0.15% | Up to 0.04% | Up to 0.03% | Up to 0.02% |

Hastelloy Metal Alloy Mechanical Properties

Huaxiao Metal Supplier has the alloy products for sale online. The mechanical properties of Hastelloy are very prominent, characterized by high strength and high toughness, which makes it challenging in machining. Moreover, has a strong strain hardening tendency, with a strain rate of 15%, about twice that of 18-8 stainless steel. Hastelloy has a medium-temperature sensitization zone, and its sensitization tendency increases with the increase of the strain rate. When the temperature is high, Hastelloy prone to absorbing harmful elements, leading to a decrease in its mechanical and corrosion resistance properties. The products is for sale.

| Hastelloy Alloy Grade | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Hardness (HB or HRC) | Elastic Modulus (GPa) | Thermal Conductivity (W/mK) |

|---|---|---|---|---|---|---|

| Hastelloy C-276 | 550-760 | ≥240 | ≥30 | – | 210 | 10.5 (at 20-100°C) |

| Hastelloy B-3 | ≥480 | ≥205 | – | ≤220 (HRB) | 216 | 10 (approx.) |

| Hastelloy C-22 | ≥690 | – | ≥40 | – | – | – |

What is Hastelloy?

Hastelloy, a trademark of Haynes International Inc., is renowned for its corrosion resistance and high-temperature strength. It is a high-performance nickel-based alloy that plays a crucial role in various industries requiring high strength, corrosion resistance, and heat resistance.Commercial market is popular,and fabrication of hastelloy corrosion resistant alloys.

Hastelloy Alloy Characteristics

Corrosion Resistance

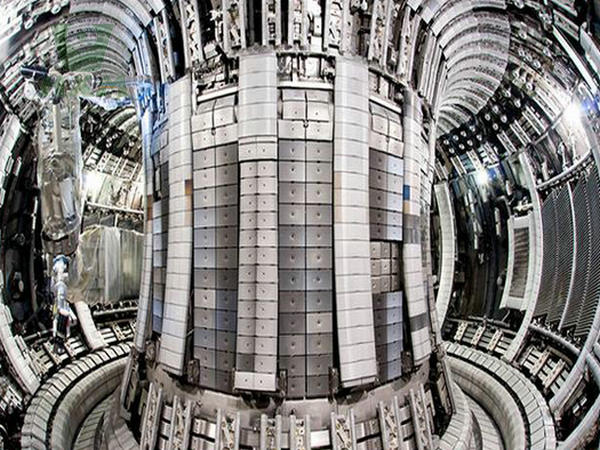

Hastelloy alloys are famous for their excellent corrosion resistance, especially in environments containing aggressive fluids or aggressive media. The chromium content in Hastelloy provides powerful antioxidant properties, while nickel and molybdenum enhance its corrosion resistance. This makes Hastelloy an ideal choice for applications in the chemical, petrochemical, and nuclear industries, where it can withstand the corrosive effects of various chemicals and high temperatures.

High-Temperature Strength

Hastelloy X, are high-performance Fe-Ni-Cr-based solid-solution strengthened deformation high-temperature alloys. They exhibit outstanding high-temperature strength and stability, allowing them to be used in applications such as aerospace engine components, industrial furnace equipment, and gas turbine components. In these environments, Hastelloy can maintain its mechanical properties and structural integrity even at elevated temperatures. Huaxiao Metal Manufacturer provides various products.

Versatility in Applications

Due to its unique combination of properties, Hastelloy is versatile and can be used in a wide range of applications. In the aerospace industry, it is used in components such as combustion chambers, rectifiers, and structural covers. In the petrochemical industry, it is used in spiral tubes, heat exchangers, and other equipment. Additionally, Hastelloy is also used in nuclear energy, pharmaceutical manufacturing, and environmental engineering industries.

Fabrication and Processing

The production and processing of Hastelloy require strict technical control to ensure the accuracy and uniformity of alloy composition, thereby guaranteeing stable alloy performance. Due to its high hardness and toughness, specialized processing equipment and techniques are required for fabrication and welding. However, despite these challenges, Hastelloy’s excellent properties and wide range of applications make it an indispensable alloy material. Our factory is manufacturing various kinds products for sale.

Hastelloy Metal Alloy Application

Hastelloy plays a crucial role in various industrial fields to their excellent corrosion resistance and high-temperature strength. Their wide range of applications and superior performance reflect their importance and value in modern industry. Huaxiao Metal Supplier has the afforrable price for sale.

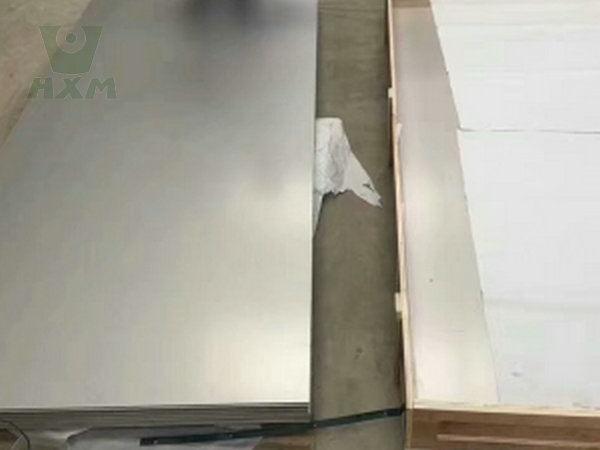

Customized Package

Our packaging solutions for Hastelloy involve multiple layers of protective materials, including moisture barriers and shock absorbers, to safeguard against physical damage and environmental contaminants.Welcome to request price.

Each Hastelloy product is securely sealed in robust containers designed to withstand the rigors of transportation and storage. Clear labeling and comprehensive documentation accompany each shipment for easy identification and traceability. Our commitment to meticulous packaging ensures that Hastelloy alloys arrive in perfect condition, ready for your demanding applications. The stock is aboundant and enough.

FAQ

hastelloy c276 vs alloy 20

Hastelloy C276 and Alloy 20 are high-performance alloy materials with excellent resistance and high-temperature stability. They differ in chemical composition, performance characteristics, and applications, but both are indispensable in various industrial fields

What is fabrication of hastelloy corrosion resistant alloys?

Throughout the fabrication process, it is crucial to maintain cleanliness and avoid contamination of the Hastelloy alloy to ensure its corrosion resistance and other properties are not compromised. Additionally, fabrication of Hastelloy alloys should be performed by skilled and experienced personnel who are familiar with the specific properties and requirements of these alloys.

Overall, the fabrication of Hastelloy corrosion-resistant alloys is a complex and specialized process that requires careful attention to detail and adherence to strict quality control standards.

hastelloy c2000 and hastelloy c4 Advantages

The advantages of Hastelloy C2000 lie in its excellent corrosion resistance, capable of withstanding the erosion of various strong acids,alis, and salt solutions, as well as its high temperature strength and good resistance to stress corrosion cracking. On the other hand, Hastelloy C4 is for its outstanding corrosion resistance, high temperature stability, good machinability, and wear resistance, making it suitable for a variety of extreme environments.

How is hastelloy alloy market?

The Hastelloy alloy market is a dynamic and expanding field with diverse applications and ongoing technological advancements. With increasing demand from key industries and a competitive market landscape, players in this sector must continue to innovate and adapt to meet the evolving needs of their customers.