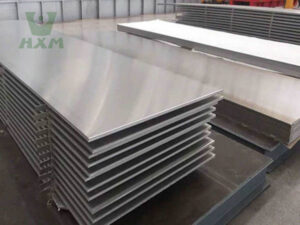

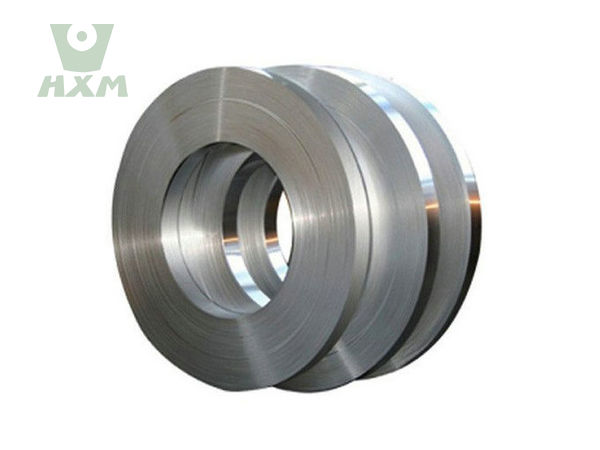

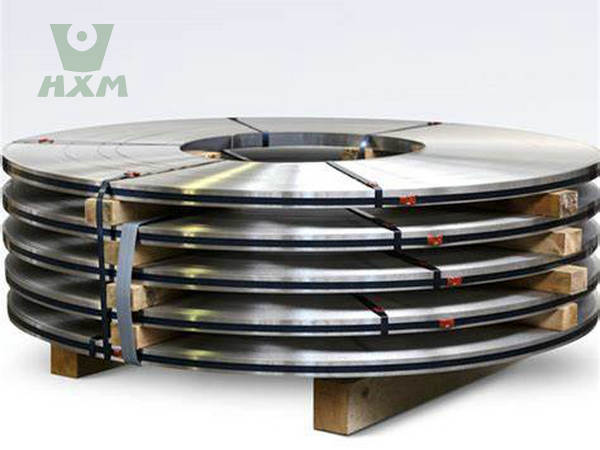

Hastelloy is a family of nickel-based alloys known for their exceptional resistance to corrosion, high-temperature stability, and mechanical strength. Among the various forms of Hastelloy products, Hastelloy alloy strips are widely used in industries that demand reliability in harsh environments. This blog provides a detailed overview of Hastelloy alloy plates, covering their specifications, chemical composition, physical and mechanical properties, benefits, procurement tips, cost-effectiveness, manufacturing, pricing insights, and applications.Huaxiao Metal Supplier has the various hastelloy alloy strip and the quality is good in China.

Overview of Hastelloy Strip Alloy

Hastelloy alloy strips are renowned for their exceptional corrosion resistance, high temperature stability, and mechanical strength. This nickel-based alloy, primarily comprising nickel, molybdenum, chromium, and other trace elements, finds extensive application in industries like chemicals, petrochemicals, energy production, and pollution control. The unique chemical composition and microstructure of Hastelloy alloy strips make them ideal for harsh environments where conventional materials fail. Huaxiao Metal Supplier has the good service and assurance of alloy products.

Hastelloy Strip Alloy Specification

Hastelloy alloy strips are available in various specifications, including different diameters, thicknesses, and lengths, tailored to meet specific industrial requirements. Common specifications include ASTM and UNS standards, ensuring consistent quality and performance.

Hastelloy strip alloy is available in various grades, with Hastelloy C-276 being one of the most widely used. Specifications for Hastelloy C-276 strip alloy include ASTM B575, ASTM B906, ISO 6208, and DIN 17750, ensuring compliance with international standards. It is hardened only by cold-working and can operate within a temperature range from cryogenic levels to 750°F (400°C).

Hastelloy strips are available in various grades, each tailored for specific applications. The most common grades include:

Hastelloy C276: Excellent resistance to pitting, crevice corrosion, and stress corrosion cracking.

Hastelloy C22: Superior resistance to oxidizing and reducing environments.

Hastelloy B2: Ideal for highly reducing environments, such as hydrochloric acid.

These strips comply with international standards such as ASTM B575 (for plates, sheets, and strips) and ASTM B622 (for seamless pipes and tubes).

Chemical Composition of Hastelloy Strip

Huaxiao Metal Manufacturer has the good service and delievery for customerized solutions. Our products are carefully crafted with precision and attention to detail, ensuring that they meet the highest standards of quality and functionality.

The chemical composition of Hastelloy C-276 strip alloy is precisely balanced to enhance its corrosion resistance and mechanical properties. The nominal composition includes:

| Element | Range (%) |

|---|---|

| Molybdenum (Mo) | 15.0 – 17.0 |

| Chromium (Cr) | 14.5 – 16.5 |

| Iron (Fe) | 4.0 – 7.0 |

| Tungsten (W) | 3.0 – 4.5 |

| Cobalt (Co) | ≤ 2.5 |

| Carbon (C) | ≤ 0.010 |

| Silicon (Si) | ≤ 0.08 |

| Manganese (Mn) | ≤ 1.0 |

| Vanadium (V) | ≤ 0.35 |

| Phosphorus (P) | ≤ 0.04 |

| Sulfur (S) | ≤ 0.03 |

| Nickel (Ni) | Balance |

Physical Properties of Hastelloy Strip

Hastelloy strips exhibit remarkable physical properties, as shown in the table below:

| Property | Value |

|---|---|

| Density | 8.89 g/cm³ |

| Melting Point | 1370°C – 1399°C (2500°F – 2550°F) |

| Thermal Conductivity | 10.2 W/m·K (at 100°C) |

| Electrical Resistivity | 1.29 µΩ·m (at 20°C) |

| Magnetic Permeability | 1.0001 (non-magnetic) |

These properties make Hastelloy strips suitable for applications requiring thermal stability and electrical conductivity.

Hastelloy C-276 strip alloy exhibits distinct physical properties that make it suitable for high-temperature and corrosive environments. Key physical properties include:

- Density: 0.321 lb/in³ (8.89 g/cm³)

- Modulus of Elasticity (E): 29.7 x 10³ ksi (205 GPa) at 70°F (20°C)

- Modulus of Rigidity (G): 11.5 x 10³ ksi (79.0 GPa) at 70°F (20°C)

- Coefficient of Thermal Expansion: 6.78 µin/in.-°F (70°F to 600°F) or 12.2 µm/m-°C (20°C to 300°C)

- Electrical Resistivity: 51 µΩ.in (130 µΩ.cm)

- Thermal Conductivity: 68.0 Btu-in/ft²hr-°F (9.80 W/m-K)

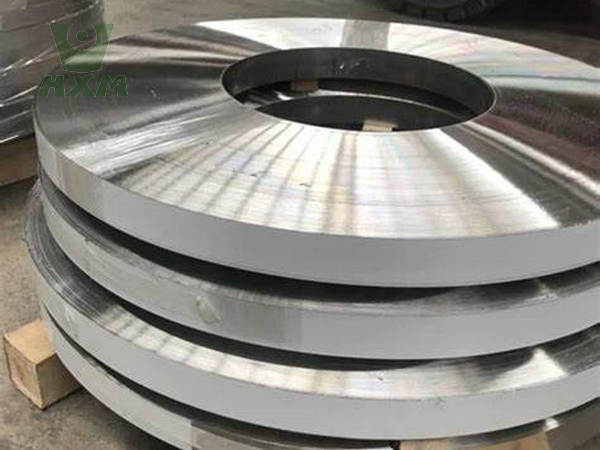

Huaxiao Metal Manufacturer also provides other shapes of Hastelloy Alloy products, such as plate&sheet, bar, coil,wire&mesh, tube&pipe, strip. The price is affordable and suitable.

Mechanical Properties of Hastelloy Strip

The mechanical properties of Hastelloy strips vary depending on the grade and heat treatment. Below is a comparison for Hastelloy C276:

| Property | Annealed Condition |

|---|---|

| Tensile Strength | 790 MPa (115 ksi) |

| Yield Strength | 415 MPa (60 ksi) |

| Elongation | 40% |

| Hardness (Rockwell B) | 90 – 100 |

The alloy’s high tensile and yield strengths, combined with excellent elongation, make it ideal for high-stress applications.

- Tensile Strength: 120 – 160 ksi (830 – 1100 MPa)

- Spring Temper Tensile Strength: 200 – 240 ksi (1380 – 1655 MPa)

These properties, combined with its resistance to pitting, crevice corrosion, and stress corrosion cracking, make Hastelloy C-276 an ideal material for springs, heat exchangers, bellows, and seals.

These alloy strips offer excellent mechanical properties, including high tensile strength, yield strength, and elongation. They also demonstrate good creep resistance and fatigue strength at elevated temperatures. The mechanical properties of Hastelloy alloy plates make them suitable for applications requiring high structural integrity and durability. Our company has the good quality hastelloy products and the service is customerized for every customers.

Benefits of Using Hastelloy Strip

Hastelloy strip alloy, a nickel-based alloy renowned for its exceptional corrosion resistance and high-temperature strength, is a material of choice for numerous demanding applications across various industries. Developed by Haynes International, Hastelloy alloys encapsulate a series of high-performance materials tailored to resist degradation in harsh environments. This product introduction delves into the specifications, chemical composition, physical and mechanical properties, benefits, procurement tips, cost-effectiveness, manufacturing insights, pricing, and industrial applications of Hastelloy strip alloy.

Huaxiao Metal Supplier provides professional services and reasonable prices, offering customers the best quality products. The benefits of using Hastelloy alloy strips are numerous:

- Corrosion Resistance: Exceptional resistance to a wide range of corrosive media, including acids, chlorides, and oxidizing agents.

- High Temperature Stability: Maintains performance at elevated temperatures, suitable for applications up to 1350°C.

- Mechanical Strength: High tensile and yield strengths ensure durability and reliability.

- Formability and Weldability: Easily formed and welded into complex shapes and structures.

Huaxiao Metal Supplier provides all kinds of hastelloy alloy products in the world. Welcome to inquiry and ask for the lastest price. Looking forward to your email, which I am convienced that you will be satisfied to our products.

Hastelloy Strip Tips for Procurement and Cost-Effectiveness

Huaxiao Metal Supplier provides professional services and reasonable prices, offering customers the best quality products. When procuring Hastelloy alloy strips, consider the following tips for cost-effectiveness:

Supplier Selection: Choose suppliers with certifications (e.g., ISO, ASTM) to ensure quality.

Bulk Purchasing: Buying in bulk can reduce costs.

Customization: Opt for tailored dimensions to minimize waste.

Market Trends: Monitor nickel and molybdenum prices, as they influence Hastelloy pricing.

Hastelloy Strip Procurement

When procuring Hastelloy strips, consider the following:

Standards Compliance: Ensure the material meets ASTM B575 or other relevant standards.

Testing Certificates: Request mill test reports (MTRs) for quality assurance.

Lead Time: Plan for potential delays due to high demand.

Hastelloy Strip Cost-Effectiveness

While Hastelloy strips are more expensive than stainless steel, their longevity and reduced maintenance costs make them cost-effective in the long run. For example:

Initial Cost: 25−25−40 per pound (varies with market conditions).

Lifecycle Cost: Lower due to minimal replacement and repair needs.

Huaxiao Metal Supplier provides professional services and reasonable prices, offering customers the best quality products. The Titanium Alloy Factory is a specialized manufacturing facility dedicated to the production of high-quality titanium alloy. This factory combines advanced technology, rigorous quality control, and experienced personnel to ensure the production of titaium alloy the highest standards.The factory is equipped with state-of-the-art production equipment and machinery, capable of producing titanium alloy with precise dimensions and consistent quality.Welcome to reqiure, and ask to the lastest price list.

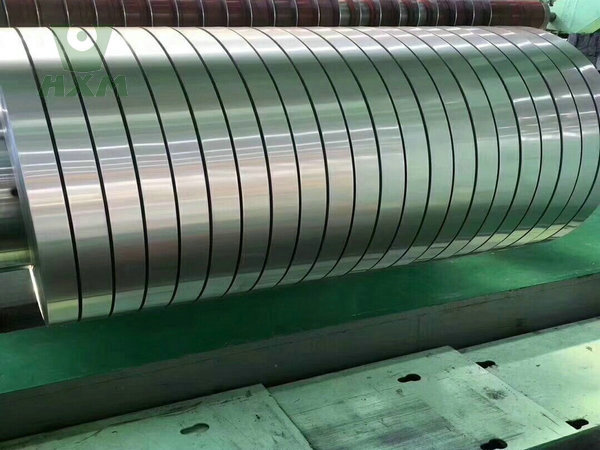

Hastelloy Strip Manufacturing and Cost

Huaxiao Metal Supplier has many of hastelloy plate products in China, and the quality is good . Our company has the good services to every customers to the complete solutions.

The manufacturing process of Hastelloy strip alloy involves melting various metal raw materials in a specific proportion, followed by cooling and solidification. Techniques such as melting, chemical reduction, and electrolytic deposition are used to produce Hastelloy alloys. Manufacturing costs are influenced by raw material prices, production processes, and yield rates.

The manufacturing process involves:

Manufacturing and Cost

The manufacturing process involves melting, casting, hot rolling, and annealing. Costs are influenced by:

Raw Material Prices: Nickel and molybdenum prices.

Processing Techniques: Annealing increases ductility but also costs.

Labor and Energy Costs: Vary by region.

Hastelloy Strip Pricing Insights

Huaxiao Metal Supplier has the suitable price and the solution for you customerized .Pricing for Hastelloy alloy coils varies based on market conditions, alloy grade, specifications, and supplier. Prices tend to be higher due to the alloy’s superior properties and complex manufacturing process. However, long-term cost savings can be achieved through efficient procurement strategies and reliable supplier relationships.Below is a comparison of Hastelloy C276 pricing with other alloys:

Pricing Insights

Pricing for Hastelloy strip alloy varies based on factors such as alloy grade, market demand, and supply chain dynamics. Regular market analysis and cost-benefit assessments are crucial for making informed purchasing decisions. Below is a comparison of Hastelloy C276 strip pricing with other alloys:

| Alloy | Price per Pound (USD) |

|---|---|

| Hastelloy C276 | 25−25−40 |

| Monel 400 | 15−15−25 |

| Inconel 625 | 20−20−30 |

Despite its higher cost, Hastelloy C276 offers superior performance in corrosive and high-temperature environments.

Applications of Hastelloy Strip in Various Industries

Huaxiao Metal Manufacturer will provide the good quality hastelloy coil, and the delievery is fast, service id good. Hastelloy alloy strips are widely used in various industries:

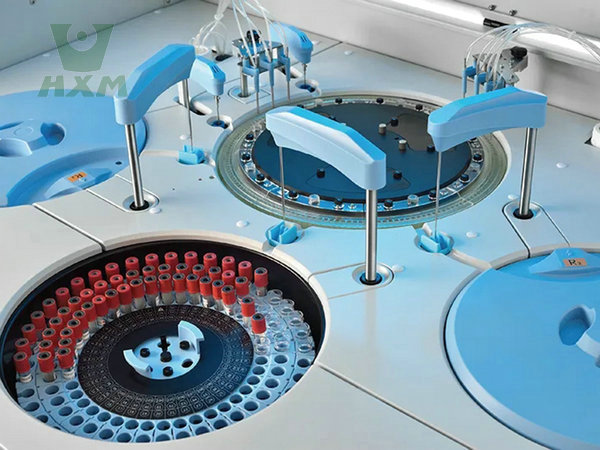

Chemical Processing: Reactors, heat exchangers, and piping systems.

Oil and Gas: Downhole equipment, offshore platforms, and pipelines.

Aerospace: Turbine blades and combustion chambers.

Power Generation: Flue gas desulfurization systems and nuclear reactors.

Pharmaceuticals: Equipment for handling corrosive chemicals.

Data Analysis and Comparison

To further illustrate the advantages of Hastelloy C276 strip, consider the following comparison table:

| Property | Hastelloy C276 | Monel 400 | Inconel 625 |

|---|---|---|---|

| Corrosion Resistance | Excellent | Excellent | Excellent |

| Tensile Strength (MPa) | 790 | 550 – 760 | 930 |

| Cost (USD/lb) | 25−25−40 | 15−15−25 | 20−20−30 |

| Temperature Range | -200°C to 1093°C | -240°C to 540°C | -200°C to 980°C |

This analysis highlights Hastelloy C276’s balanced performance in terms of strength, corrosion resistance, and cost, making it a reliable choice for critical application.

In Conclusion

Hastelloy alloy strips are high-performance materials offering unmatched corrosion resistance, high-temperature stability, and mechanical strength. Their versatility and cost-effectiveness make them a preferred choice for demanding applications across industries. By understanding their properties, procurement strategies, and market dynamics, businesses can maximize the value of these exceptional materials. Our products are guaranteed in quality, and our professional team can provide technical support and consulting services. If you need more information or have any questions, please free to contact our customer service team.

Hastelloy strip alloy is a high-performance material offering unmatched corrosion resistance, high-temperature stability, and mechanical strength. Its versatility and cost-effectiveness make it a preferred choice for demanding applications across industries. By understanding its properties, procurement strategies, and market dynamics, businesses can maximize the value of this exceptional material.

Huaxiao Metal Supplier is professional and experienced in alloy producing factory, our company provides the personalized services and welcome to inquiry about the lastest price. Hastelloy alloy strips are indispensable in industries requiring high corrosion resistance, high temperature stability, and mechanical strength. Their unique chemical composition and physical properties make them ideal for harsh environments and complex applications. By understanding their specifications, chemical composition, physical and mechanical properties, and procurement strategies, businesses can leverage the full potential of Hastelloy alloy coils to enhance product performance and reduce costs. Our engineers and metallurgists will be pleased to provide further data and applications advice.