Hastelloy is a family of nickel-based alloys known for their exceptional resistance to corrosion, high-temperature stability, and mechanical strength. Among the various forms of Hastelloy products, Hastelloy alloy bars are widely used in industries that demand reliability in harsh environments. This blog provides a detailed overview of Hastelloy alloy plates, covering their specifications, chemical composition, physical and mechanical properties, benefits, procurement tips, cost-effectiveness, manufacturing, pricing insights, and applications.Huaxiao Metal Supplier has the various hastelloy alloy bar and the quality is good in China.

Overview of Hastelloy Bar Alloy Source

Hastelloy alloy bars are renowned for their exceptional corrosion resistance, high temperature stability, and mechanical strength. This nickel-based alloy, primarily comprising nickel, molybdenum, chromium, and other trace elements, finds extensive application in industries like chemicals, petrochemicals, energy production, and pollution control. The unique chemical composition and microstructure of Hastelloy alloy coils make them ideal for harsh environments where conventional materials fail. Huaxiao Metal Supplier has the good service and assurance of alloy products.

| Grade | Primary Applications | Key Features |

|---|---|---|

| C-276 | Chemical reactors, flue gas desulfurization | Excellent resistance to oxidizing and reducing acids, chloride stress corrosion |

| C-22 | Oil/gas pipelines, heat exchangers | Enhanced resistance to pitting and crevice corrosion in chloride environments |

| B-2 | Hydrochloric acid production | Superior resistance to pure sulfuric and hydrochloric acids |

Hastelloy Bar Alloy Specification

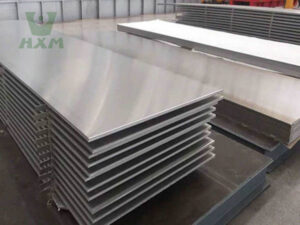

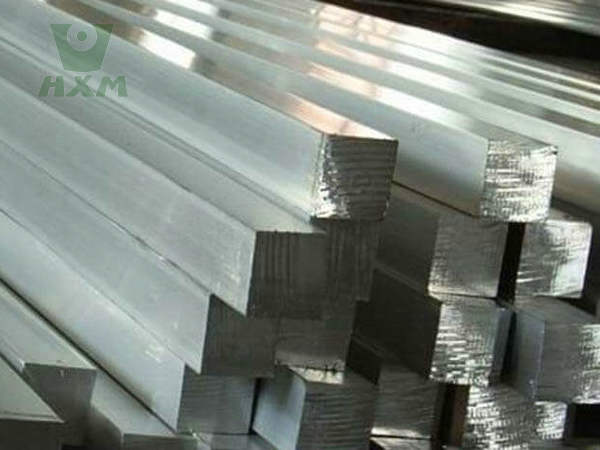

Hastelloy bars are high-performance nickel-based alloys renowned for their exceptional resistance to corrosion, high temperatures, and extreme environments. These alloys are widely used in industries such as chemical processing, aerospace, oil and gas, and power generation. This blog provides a detailed, professional, and customer-friendly analysis of Hastelloy bars, covering their specifications, properties, benefits, procurement tips, and applications. Whether you’re a procurement manager, engineer, or industry professional, this guide will equip you with the knowledge to make informed decisions.Hastelloy alloy bars are available in various specifications, including different diameters, thicknesses, and lengths, tailored to meet specific industrial requirements. Common specifications include ASTM and UNS standards, ensuring consistent quality and performance.

Huaxiao Metal Manufacturer has the good service and delievery for customerized solutions. Our products are carefully crafted with precision and attention to detail, ensuring that they meet the highest standards of quality and functionality.

Hastelloy is a family of nickel-based alloys that include elements such as molybdenum, chromium, and iron. These alloys are designed to withstand harsh environments, including acidic, alkaline, and high-temperature conditions. Hastelloy bars are available in various grades, such as Hastelloy C276, Hastelloy B2, and Hastelloy X, each tailored for specific applications.

| Property | Details |

|---|---|

| Alloy Family | Nickel-Based Alloys |

| Common Grades | C276, B2, B3, C22, X |

| Forms | Round bars, flat bars, square bars |

| Standards | ASTM B574, ASTM B575, ASME SB574, DIN 17752 |

| Surface Finish | Polished, turned, peeled |

Chemical Composition of Hastelloy Bar Alloy Source

The chemical composition of Hastelloy alloys varies by grade. Below is the composition for Hastelloy C276, one of the most widely used grades:

| Element | Composition (%) |

|---|---|

| Nickel (Ni) | Balance |

| Molybdenum (Mo) | 15 – 17 |

| Chromium (Cr) | 14.5 – 16.5 |

| Iron (Fe) | 4 – 7 |

| Tungsten (W) | 3 – 4.5 |

| Cobalt (Co) | ≤ 2.5 |

| Manganese (Mn) | ≤ 1 |

| Silicon (Si) | ≤ 0.08 |

| Carbon (C) | ≤ 0.01 |

Physical Properties of Hastelloy Bar

| Property | Value |

|---|---|

| Density | 8.89 g/cm³ |

| Melting Point | 1323°C – 1371°C |

| Thermal Conductivity | 10.1 W/m·K |

| Electrical Resistivity | 1.29 µΩ·m |

| Coefficient of Thermal Expansion | 11.2 x 10⁻⁶/°C |

Huaxiao Metal Manufacturer also provides other shapes of Hastelloy Alloy products, such as plate&sheet, bar, coil,wire&mesh, tube&pipe, strip. The price is affordable and suitable.

Mechanical Properties of Hastelloy Bar

| Property | Hastelloy C276 |

|---|---|

| Tensile Strength | 790 MPa |

| Yield Strength | 415 MPa |

| Elongation | 40% |

| Hardness (Rockwell B) | 100 |

These alloy bars offer excellent mechanical properties, including high tensile strength, yield strength, and elongation. They also demonstrate good creep resistance and fatigue strength at elevated temperatures. The mechanical properties of Hastelloy alloy bars make them suitable for applications requiring high structural integrity and durability. Our company has the good quality hastelloy products and the service is customerized for every customers.

Benefits of Using Hastelloy Bar

Huaxiao Metal Supplier provides professional services and reasonable prices, offering customers the best quality products. The benefits of using Hastelloy alloy bars are numerous:

Exceptional Corrosion Resistance: Resists pitting, crevice corrosion, and stress corrosion cracking.

High-Temperature Stability: Maintains strength and integrity at elevated temperatures.

Versatility: Suitable for a wide range of aggressive environments.

Long Service Life: Reduces downtime and maintenance costs.

Weldability: Can be welded using standard techniques without losing properties.

Huaxiao Metal Supplier provides all kinds of titanium alloy products in the world. Welcome to inquiry and ask for the lastest price. Looking forward to your email, which I am convienced that you will be satisfied to our products.

Hastelloy Bar Tips for Procurement and Cost-Effectiveness

Huaxiao Metal Supplier provides professional services and reasonable prices, offering customers the best quality products. When procuring Hastelloy alloy bars, consider the following tips for cost-effectiveness:

- Identify Specific Requirements: Clearly define the application and environmental conditions to select the most suitable alloy grade.

- Compare Suppliers: Evaluate multiple suppliers based on quality, price, delivery times, and customer service.

- Bulk Purchasing: Consider bulk purchases to negotiate lower prices and reduce unit costs.

- Long-term Contracts: Establish long-term contracts with reliable suppliers to ensure consistent supply and potential cost savings.

Hastelloy Bar Procurement

Supplier Certification: Ensure suppliers meet standards like ISO 9001 and NORSOK.

Grade Selection: Choose the appropriate grade (e.g., C276 for chemical processing, B2 for reducing environments).

Bulk Purchasing: Negotiate discounts for large orders.

Quality Assurance: Request material test certificates (MTC) and third-party inspections.

Lead Time: Plan procurement to avoid delays in project timelines.

Procurement Channels: Source directly from manufacturers or authorized distributors.

Cost Factors: Grade, size, and quantity influence pricing.

Value for Money: Hastelloy bars offer long-term savings due to their durability and low maintenance.

Hastelloy Bar Cost-Effectiveness

Manufacturing Process: Melting, forging, and heat treatment.

Cost Drivers: Raw material prices, energy costs, and labor expenses.

Economies of Scale: Larger production volumes reduce per-unit costs.

Huaxiao Metal Supplier provides professional services and reasonable prices, offering customers the best quality products. The Hastelloy Alloy Factory is a specialized manufacturing facility dedicated to the production of high-quality hastelloy alloy. This factory combines advanced technology, rigorous quality control, and experienced personnel to ensure the production of hastelloy alloy the highest standards.The factory is equipped with state-of-the-art production equipment and machinery, capable of producing t alloy with precise dimensions and consistent quality.Welcome to reqiure, and ask to the lastest price list.

Hastelloy Bar Manufacturing and Cost

Huaxiao Metal Supplier has many of hastelloy bars products in China, and the quality is good . Our company has the good services to every customers to the complete solutions. The manufacturing process involves:

The manufacturing process of Hastelloy alloy bars involves complex metallurgical operations, including melting, casting, rolling, and heat treatment. The cost of manufacturing is influenced by factors such as raw material prices, energy consumption, and production efficiency.

The manufacturing process involves melting, casting, hot rolling, and annealing. Costs are influenced by:

Raw Material Prices: Nickel and molybdenum prices.

Processing Techniques: Annealing increases ductility but also costs.

Labor and Energy Costs: Vary by region.

To highlight the superiority of Hastelloy alloys, below is a comparative analysis with other materials:

| Property | Hastelloy C276 | Stainless Steel 316 | Inconel 625 |

|---|---|---|---|

| Corrosion Resistance | Excellent | Good | Excellent |

| High-Temperature Strength | Excellent | Moderate | Excellent |

| Cost | High | Low | High |

| Weldability | Excellent | Good | Excellent |

| Applications | Chemical, Aerospace | General Purpose | Aerospace, Marine |

Hastelloy Bar Pricing Insights

Huaxiao Metal Supplier has the suitable price and the solution for you customerized .Pricing for Hastelloy alloy bars varies based on market conditions, alloy grade, specifications, and supplier. Prices tend to be higher due to the alloy’s superior properties and complex manufacturing process. However, long-term cost savings can be achieved through efficient procurement strategies and reliable supplier relationships.Below is a comparison of Hastelloy C276 pricing with other alloys:

Price Range: 30−30−100 per kg (varies by grade and market conditions).

Market Trends: Prices fluctuate based on nickel and molybdenum markets.

Competitive Edge: Hastelloy alloys outperform stainless steel and other nickel alloys in harsh environments, justifying their premium cost.

Applications of Hastelloy Bar in Various Industries

Huaxiao Metal Manufacturer will provide the good quality hastelloy bar, and the delievery is fast, service id good. Hastelloy alloy coils are widely used in various industries:

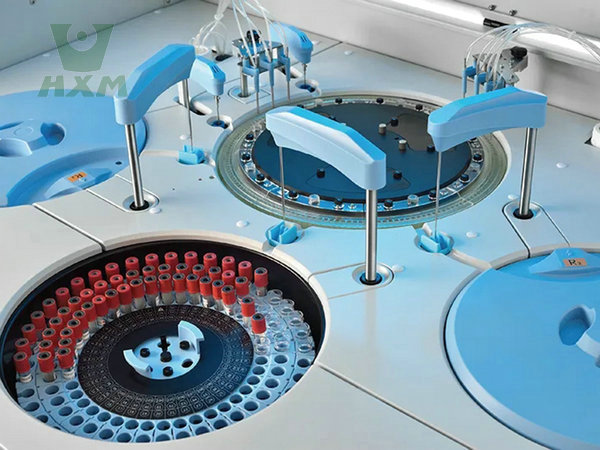

- Chemical Industry: Reactors, pipelines, and storage tanks handling corrosive chemicals.

- Petrochemical Industry: Equipment exposed to hydrochloric acid, sulfuric acid, and other corrosive gases.

- Energy Production: Components in gas turbines, waste heat boilers, and desulfurization systems.

- Pollution Control: Equipment for flue gas desulfurization, waste incineration, and emission control.

| Industry | Application |

|---|---|

| Chemical Processing | Reactors, heat exchangers, piping |

| Aerospace | Jet engines, turbine components |

| Oil and Gas | Downhole equipment, valves, pumps |

| Power Generation | Gas turbines, nuclear reactors |

| Pharmaceuticals | Reaction vessels, storage tanks |

In Conclusion

Hastelloy alloy bars are high-performance materials offering unmatched corrosion resistance, high-temperature stability, and mechanical strength. Their versatility and cost-effectiveness make them a preferred choice for demanding applications across industries. By understanding their properties, procurement strategies, and market dynamics, businesses can maximize the value of these exceptional materials. Our products are guaranteed in quality, and our professional team can provide technical support and consulting services. If you need more information or have any questions, please free to contact our customer service team.

Huaxiao Metal Supplier is professional and experienced in alloy producing factory, our company provides the personalized services and welcome to inquiry about the lastest price. Hastelloy alloy bars are indispensable in industries requiring high corrosion resistance, high temperature stability, and mechanical strength. Their unique chemical composition and physical properties make them ideal for harsh environments and complex applications. By understanding their specifications, chemical composition, physical and mechanical properties, and procurement strategies, businesses can leverage the full potential of Hastelloy alloy bars to enhance product performance and reduce costs. Our engineers and metallurgists will be pleased to provide further data and applications advice.

Hastelloy bars are a cornerstone of modern engineering, offering unmatched performance in corrosive and high-temperature environments. Their unique properties make them indispensable in industries where reliability and durability are paramount. By understanding their specifications, benefits, and procurement strategies, businesses can optimize their operations and achieve long-term value.