An alloy steel is a material formed by heating and fusing two or more metals, or a metal with one or more non – metals, resulting in a substance with metallic properties. This process combines the characteristics of the constituent elements to create a new material with enhanced or tailored properties compared to its pure metal counterparts. This alloy is renowned for its excellent strength-to-weight ratio, corrosion resistance, and biocompatibility. Huaxiao Metal Supplier has the various alloy and the quality is good in China.

Overview of Alloy Steel

Alloy steel stands as a cornerstone material in modern engineering, distinguished from carbon steel by the intentional addition of alloying elements. These additions—ranging from chromium and nickel to molybdenum and vanadium—transform the base iron-carbon alloy into a material tailored for specific industrial demands. This blog dissects alloy steel’s chemical makeup, physical and mechanical properties, industrial applications, cost dynamics, and high-performance use cases.

Alloy Steel Specification

Chemical Composition of Alloy Steel

| Alloying Element | Effect on Steel | Common Grades |

|---|---|---|

| Chromium (Cr) | Increases hardness & corrosion resistance | 4140, 4340 |

| Nickel (Ni) | Enhances toughness & impact resistance | 4340, 9310 |

| Molybdenum (Mo) | Improves strength at high temperatures | 4140, 8620 |

| Vanadium (V) | Refines grain structure for strength | AISI 6150 |

| Manganese (Mn) | Increases hardenability & wear resistance | 1345, 15B35 |

Physical Properties of Alloy Steel

| Property | Value Range | Significance |

|---|---|---|

| Density | 7.85 g/cm³ | Similar to carbon steel |

| Melting Point | 1420-1540°C | Higher than aluminum alloys |

| Thermal Conductivity | 45-65 W/m·K | Lower than copper |

| Electrical Conductivity | 8-12% IACS | Poor conductor (compared to copper) |

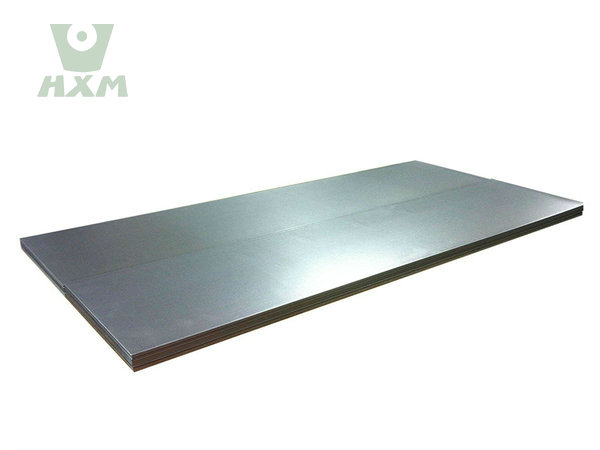

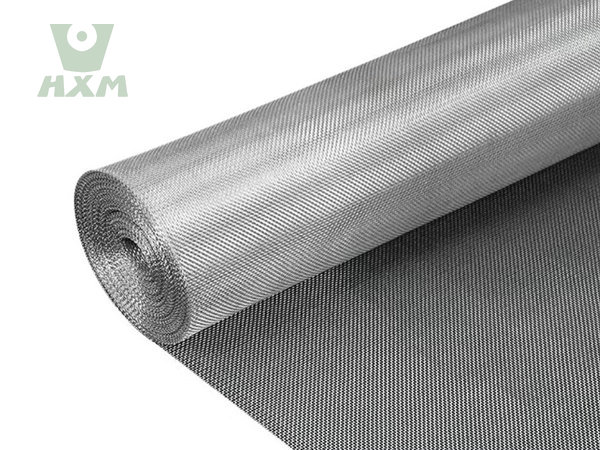

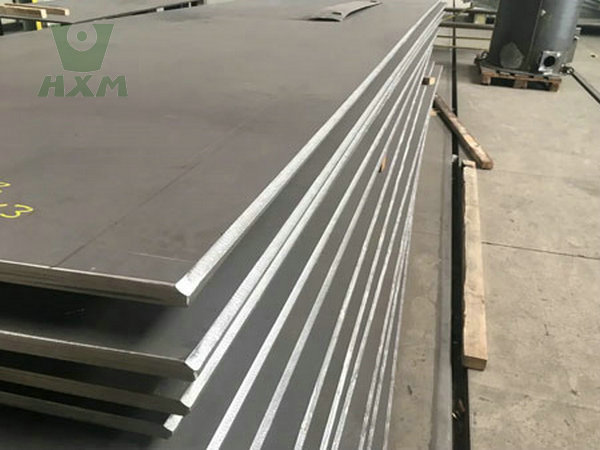

Huaxiao Metal Manufacturer also provides other shapes of Titanium Alloy products, such as plate&sheet, bar, coil,wire&mesh, tube&pipe, strip. The price is affordable and suitable.

Mechanical Properties of Alloy

| Grade | Tensile (MPa) | Yield (MPa) | Elongation (%) | Hardness (HRC) |

|---|---|---|---|---|

| 4140 | 850-1000 | 650-800 | 15-20 | 28-32 |

| 4340 | 950-1100 | 850-1000 | 12-15 | 32-36 |

| 8620 | 650-850 | 450-600 | 20-25 | 22-28 |

Benefits of Using Alloy Steel

Alloy Steel (4130/4140/4340)

✅ Customizable Properties: Tailored hardness, toughness, and corrosion resistance via alloy adjustments.

✅ High Strength-to-Weight Ratio: Critical for aerospace, automotive, and oil drilling components.

✅ Heat Treatability: Quenching and tempering optimize mechanical properties for specific use cases.

✅ Cost-Effectiveness: A balance of performance and affordability compared to premium alloys like titanium.

Huaxiao Metal Supplier provides all kinds of titanium alloy products in the world. Welcome to inquiry and ask for the lastest price. Looking forward to your email, which I am convienced that you will be satisfied to our products.

Alloy Tips for Procurement and Cost-Effectiveness

| Property | 4130 Alloy Steel | 4340 Alloy Steel | 304 Stainless Steel (Comparative) |

|---|---|---|---|

| Density (g/cm³) | 7.85 | 7.85 | 7.93 |

| Tensile Strength (MPa) | 862–1,034 | 965–1,310 | 515–1,035 |

| Yield Strength (MPa) | 724–965 | 931–1,241 | ≥205 |

| Elongation (%) | 15–25 | 12–20 | ≥40 |

| Hardness (Rockwell C) | 28–32 HRC | 36–42 HRC | ≤92 HRB |

| Thermal Conductivity (W/m·K) | 44.6–50.2 | 44.6–50.2 | 16.3 |

| Magnetic Behavior | Ferromagnetic | Ferromagnetic | Non-magnetic (annealed) |

Huaxiao Metal Supplier provides professional services and reasonable prices, offering customers the best quality products. The Titanium Alloy Factory is a specialized manufacturing facility dedicated to the production of high-quality titanium alloy. This factory combines advanced technology, rigorous quality control, and experienced personnel to ensure the production of titaium alloy the highest standards.The factory is equipped with state-of-the-art production equipment and machinery, capable of producing titanium alloy with precise dimensions and consistent quality.Welcome to reqiure, and ask to the lastest price list.

Applications of Alloy in Various Industries

| Industry | Alloy Steel Use Cases | Stainless Steel Use Cases |

|---|---|---|

| Aerospace | Landing gear, engine components, fasteners | Interior cabin trim, hydraulic systems |

| Automotive | Axles, drive shafts, suspension parts | Exhaust systems, trim components |

| Oil & Gas | Drill collars, wellhead equipment, pipelines | Subsea manifolds, chemical injection systems |

| Medical | Surgical instruments, orthopedic implants | Surgical tools, MRI-compatible components |

| Construction | Structural beams, rebar, machinery frames | Architectural cladding, handrails |

In Conclusion

Alloy steel is a dynamic class of materials whose properties are sculpted by chemistry and processing. While carbon steel offers affordability and simplicity, alloy steel bridges the gap to high-performance applications requiring strength, toughness, or corrosion resistance.

- Choose alloy steel for: Structural integrity, heat treatability, and cost-effective performance in mechanical and load-bearing systems.

- Choose stainless steel for: Corrosion resistance, hygiene, and aesthetic appeal in food, medical, and marine environments.

Our products are guaranteed in quality, and our professional team can provide technical support and consulting services. If you need more information or have any questions, please free to contact our customer service team.

Huaxiao Metal Supplier is professional and experienced in alloy producing factory, our company provides the personalized services and welcome to inquiry about the lastest price.