Titanium alloys are renowned for their exceptional strength-to-weight ratio, corrosion resistance, and biocompatibility. However, with over 50 commercially available grades, selecting the right titanium alloy can be challenging. This guide breaks down the key factors to consider when choosing a titanium alloy for your application. Titanium Alloy Ti-6Al-4V (Titanium Grade 5 Alloy), also known as Grade 5 titanium, is one of the most widely used titanium alloys in the aerospace, medical, and industrial sectors. It is an alpha-beta alloy, composed primarily of titanium, aluminum, and vanadium. This alloy is renowned for its excellent strength-to-weight ratio, corrosion resistance, and biocompatibility. Huaxiao Metal Supplier has the various titanium alloy and the quality is good in China.

Overview of Titanium Grade

Titanium alloys are classified into four main groups, each with distinct properties:

| Category | Key Alloys | Characteristics | Best For |

|---|---|---|---|

| Commercially Pure (CP) Ti | Grade 1, 2, 3, 4 | Excellent corrosion resistance, low strength | Chemical processing, medical implants |

| Alpha (α) Alloys | Ti-5Al-2.5Sn | Good creep resistance, moderate strength | Aerospace (static components) |

| Alpha-Beta (α-β) Alloys | Ti-6Al-4V (Grade 5) | High strength, good weldability | Aerospace, medical, marine |

| Beta (β) Alloys | Ti-10V-2Fe-3Al | Highest strength, heat-treatable | High-stress aerospace parts |

Key Insight:

CP Titanium (Grade 2) is the most widely used due to its balance of corrosion resistance and cost.

Ti-6Al-4V (Grade 5) is the workhorse alloy, accounting for 50% of all titanium applications.

Titanium Grade Alloy Properties

Temperature Performance of Titanium Grade Alloy

| Alloy | Max Service Temp (°C) | Key Limitation |

|---|---|---|

| CP Ti (Grade 2) | 300 | Loses strength above 300°C |

| Ti-6Al-4V | 400 | Prone to creep |

| Ti-6242 | 540 | Best for jet engines |

For high-temperature applications (jet engines, exhausts):

✔ Ti-6242 (up to 540°C)

✔ Ti-1100 (up to 600°C)

Biocompatibility (Medical Use)

| Alloy | ISO 5832 Certification | Common Medical Uses |

|---|---|---|

| CP Ti (Grade 4) | ISO 5832-2 | Dental implants, screws |

| Ti-6Al-4V ELI | ISO 5832-3 | Hip/knee replacements |

| Ti-6Al-7Nb | ISO 5832-11 | Spinal implants |

Medical Grade Tip:

ELI (Extra Low Interstitial) grades are used for long-term implants due to better fatigue resistance.

Corrosion Resistance of Titanium Grade Alloy

| Environment | Best Alloy Choice |

|---|---|

| Seawater | Ti-6Al-4V, Grade 2 |

| Acids (HCl, H₂SO₄) | Grade 7 (Ti-0.2Pd) |

| High-temperature oxidation | Ti-6242 (Ti-6Al-2Sn-4Zr-2Mo) |

Note:

CP Ti (Grade 2) is excellent for general corrosion resistance.

Grade 7 (Ti-0.2Pd) is better for acidic environments but costs 2-3x more.

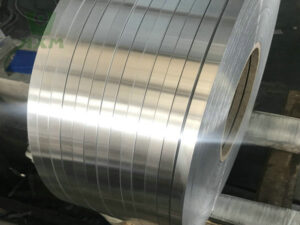

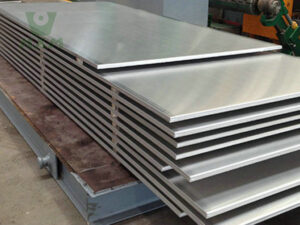

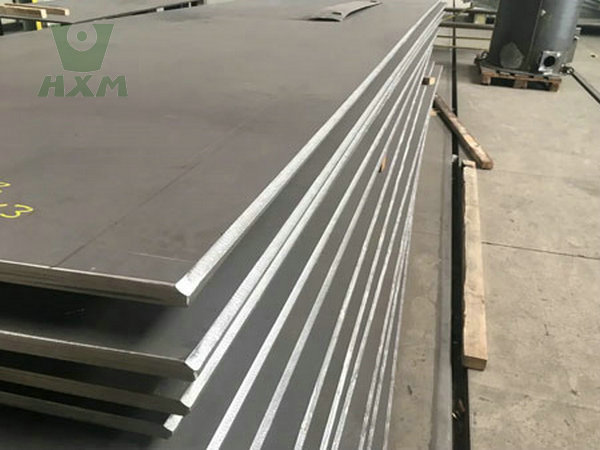

Huaxiao Metal Manufacturer also provides other shapes of Titanium Alloy products, such as plate&sheet, bar, coil,wire&mesh, tube&pipe, strip. The price is affordable and suitable.

Mechanical Properties of Titanium Alloy

| Alloy | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) |

|---|---|---|---|

| CP Grade 2 | 345-483 | 275-345 | 20-25 |

| Ti-6Al-4V | 895-930 | 825-869 | 10-15 |

| Ti-10V-2Fe-3Al | 1000-1200 | 900-1100 | 6-10 |

Rule of Thumb:

✔ High strength? → Choose β alloys (Ti-10V-2Fe-3Al)

✔ Ductility & formability? → CP Ti (Grade 2 or 3)

✔ Balanced performance? → Ti-6Al-4V (Grade 5)

| Grade | Composition | Key Properties | Main Applications |

|---|---|---|---|

| Grade 1 | >99.5% Ti | Excellent corrosion resistance, high biocompatibility, good formability | Marine components, chemical processing equipment, medical implants, jewelry |

| Grade 2 | >99% Ti, slightly higher O content | Enhanced strength, good corrosion resistance, good weldability | Chemical storage tanks, heat exchangers, marine fasteners, aircraft components |

| Grade 5 (Ti-6Al-4V) | 6% Al, 4% V, balance Ti | High strength-to-weight ratio, good corrosion resistance, heat treatable | Aerospace components, medical implants, sporting goods |

| Grade 7 | Similar to Grade 2 + 0.2% Pd | Exceptional corrosion resistance in acids, good weldability and formability | Chemical processing equipment handling acidic chemicals |

| Grade 11 | Similar to Grade 1 + 0.25% Pd | Enhanced corrosion resistance in crevices and reducing acid chloride environments, good ductility and cold formability, high impact toughness | Chemical processing, chlorate manufacturing, desalination plants, marine applications |

Advantsges and Benefits of Using Titanium Alloy

1. High Strength-to-Weight Ratio

Titanium alloys exhibit remarkable strength while maintaining a relatively low density (approximately 4.5 g/cm³), making them lighter than steel but stronger than aluminum. This property is critical in applications where weight reduction is paramount, such as in aircraft components, spacecraft, and high-performance automotive parts. The reduced weight directly translates to improved fuel efficiency and payload capacity in aerospace and transportation sectors.

2. Superior Corrosion Resistance

One of titanium’s most defining traits is its exceptional resistance to corrosion, even in harsh environments. When exposed to air or moisture, titanium forms a passive oxide layer (TiO₂) that protects the underlying metal from further degradation. This makes titanium alloys ideal for marine applications (e.g., ship hulls, propellers), chemical processing equipment, and medical implants, where exposure to corrosive substances is inevitable.

3. Excellent Biocompatibility

In the biomedical field, titanium alloys (e.g., Ti-6Al-4V) are favored for their biocompatibility—the ability to coexist harmoniously with living tissues without causing adverse reactions. This property is leveraged in dental implants, orthopedic devices (such as hip and knee replacements), and surgical instruments, where long-term compatibility with the human body is essential.

4. High-Temperature Performance

Titanium alloys retain their mechanical integrity at elevated temperatures, making them suitable for aerospace engines, gas turbines, and heat exchangers. For instance, alloys like Ti-6Al-4V can operate at temperatures up to 400°C without significant degradation in strength, outperforming many aluminum alloys in thermal stability.

5. Low Thermal Conductivity and Elastic Modulus

While these properties can pose challenges in machining (due to heat accumulation and springback), they are advantageous in specific applications:

- Low thermal conductivity reduces heat transfer in sensitive components, such as those in cryogenic systems.

- Low elastic modulus (about half that of steel) allows for better stress distribution in biomedical implants, minimizing the risk of stress shielding—a phenomenon where the implant bears too much load, leading to bone resorption.

6. Versatility in Alloying and Fabrication

Titanium’s ability to form alloys with elements like aluminum, vanadium, molybdenum, and zirconium enables tailoring of properties for specific needs. For example:

- Ti-6Al-4V (Grade 5) is widely used for its balance of strength, ductility, and weldability.

- β-Titanium alloys (e.g., Ti-35Nb-7Zr-5Ta) offer enhanced formability and elasticity, crucial for applications requiring complex shapes or spring-like behavior.

Advanced fabrication techniques, including additive manufacturing (3D printing), further expand design possibilities, enabling the creation of intricate geometries unattainable with traditional methods.

7. Environmental and Economic Benefits

Despite their higher initial cost compared to alternatives like aluminum or stainless steel, titanium alloys offer long-term savings through:

- Reduced maintenance and replacement costs due to durability.

- Energy efficiency gains from lighter structures (e.g., in aircraft).

- Recyclability, as titanium can be reused without significant loss of properties.

Moreover, titanium’s abundance in the Earth’s crust (ranked 9th most abundant element) and ongoing advancements in extraction and processing technologies make it a sustainable choice for future applications.

Huaxiao Metal Supplier provides all kinds of titanium alloy products in the world. Welcome to inquiry and ask for the lastest price. Looking forward to your email, which I am convienced that you will be satisfied to our products.

Titanium Alloy Tips for Procurement and Cost-Effectiveness

Titanium Alloy Procurement

| Alloy | Price (USD/kg) | Why the Cost? |

|---|---|---|

| CP Ti (Grade 2) | $50-80 | Low processing complexity |

| Ti-6Al-4V | $80-120 | Most widely used |

| Ti-10V-2Fe-3Al | $120-160 | High-strength, niche market |

| Grade 7 (Ti-0.2Pd) | $150-200 | Palladium addition |

Cost-Saving Tips:

✔ Use CP Ti (Grade 2) where possible (cheapest option).

✔ Consider near-net-shape manufacturing (reduces machining costs).

✔ Buy in bulk (>500kg) for 10-15% discounts.

Titanium Alloy Cost-Effectiveness

Huaxiao Metal Supplier provides professional services and reasonable prices, offering customers the best quality products. The Titanium Alloy Factory is a specialized manufacturing facility dedicated to the production of high-quality titanium alloy. This factory combines advanced technology, rigorous quality control, and experienced personnel to ensure the production of titaium alloy the highest standards.The factory is equipped with state-of-the-art production equipment and machinery, capable of producing titanium alloy with precise dimensions and consistent quality.Welcome to reqiure, and ask to the lastest price list.

Titanium Alloy Manufacturing and Cost

Machinability

| Alloy | Machinability Rating (1-10, 10=best) |

|---|---|

| CP Ti (Grade 2) | 8 |

| Ti-6Al-4V | 5 |

| Ti-10V-2Fe-3Al | 3 |

Recommendation:

CP Ti is easiest to machine (low tool wear).

Ti-6Al-4V requires carbide tools and high-pressure coolant.

Weldability

| Alloy | Weldability | Recommended Method |

|---|---|---|

| CP Ti (Grade 2) | Excellent | GTAW (TIG) |

| Ti-6Al-4V | Good (but prone to cracking) | Laser/EB welding |

| Beta Alloys | Poor | Friction stir welding |

Key Tip:

Post-weld heat treatment (PWHT) is often needed for Ti-6Al-4V.

Applications of Titanium Alloy in Various Industries

Selecting the appropriate titanium grade for your project is crucial to ensure optimal performance, cost-effectiveness, and reliability. Here are some factors to consider when making your decision:

- Application Requirements: Determine the specific requirements of your application, such as strength, corrosion resistance, formability, and biocompatibility. For example, if your application involves exposure to acidic chemicals, Grade 7 or Grade 11 titanium may be more suitable. If weight reduction is a priority, Grade 5 titanium could be the best choice.

- Environmental Conditions: Consider the environmental conditions in which the titanium component will be used. Factors such as temperature, humidity, and exposure to corrosive agents will influence the choice of titanium grade. For marine applications, grades with excellent corrosion resistance in seawater, such as Grade 1 or Grade 2, are preferred.

- Cost: Titanium grades vary in cost, with Grade 1 and Grade 2 being more affordable compared to alloyed grades like Grade 5. Evaluate your budget and balance it with the required performance of the titanium component.

- Manufacturing Processes: Different titanium grades may have different manufacturing requirements. For example, Grade 5 titanium may require more specialized heat treatment processes compared to commercially pure grades. Ensure that your manufacturing capabilities align with the chosen titanium grade.

| Industry | Best Alloy | Why? |

|---|---|---|

| Aerospace | Ti-6Al-4V | Strength-to-weight ratio |

| Medical | Ti-6Al-4V ELI | Biocompatibility |

| Marine | CP Ti (Grade 2) | Corrosion resistance |

| Chemical | Grade 7 (Ti-0.2Pd) | Acid resistance |

| Automotive | Ti-10V-2Fe-3Al | High-strength fasteners |

In Conclusion

Titanium alloys represent a paradigm of material innovation, offering a rare combination of strength, lightness, corrosion resistance, and biocompatibility. Their benefits extend across industries, driving advancements in aerospace, medicine, energy, and beyond. As technology evolves, titanium alloys are poised to play an even more prominent role in shaping the future of high-performance materials. Our products are guaranteed in quality, and our professional team can provide technical support and consulting services. If you need more information or have any questions, please free to contact our customer service team.

Huaxiao Metal Supplier is professional and experienced in alloy producing factory, our company provides the personalized services and welcome to inquiry about the lastest price.

In conclusion, choosing the right titanium grade for your application is a critical decision that requires careful consideration of various factors. By understanding the properties and characteristics of different titanium grades, you can make an informed choice that will meet the specific requirements of your project. Whether you are working in the aerospace, medical, chemical processing, or marine industry, there is a titanium grade that is perfectly suited for your needs. We hope this blog post has provided you with valuable insights to help you make the right titanium grade selection. If you have any further questions or need assistance in choosing the appropriate titanium grade for your project, feel free to reach out to our team of experts.