In an era where industrial innovation hinges on materials that defy extremes, superalloys stand as the pinnacle of metallurgical engineering. These advanced alloys—primarily nickel-based, with cobalt and iron variants—are designed to thrive where conventional metals fail: in the scorching heat of jet engines, the corrosive depths of chemical plants, and the relentless stress of nuclear reactors.

As a globally trusted supplier and manufacturer of premium metal materials since 2005, we combine decades of metallurgical expertise with state-of-the-art production capabilities to deliver unparalleled quality across our extensive product portfolio, including aerospace-grade titanium alloys, corrosion-resistant superalloys, and high-strength stainless steels—all rigorously tested to meet ISO 9001, AS9100, and ASTM/EN standards. Partner with us to experience seamless procurement, 24/7 technical support from Ph.D.-level engineers, and on-time delivery proven across 2000+ global clients—request a quote today and elevate your supply chain with reliability redefined.

What Defines a Superalloy?

A superalloy, or high-performance alloy, is distinguished by its ability to retain mechanical strength, surface stability, and resistance to oxidation/corrosion at temperatures exceeding 1,100°C (2,012°F). Unlike standard alloys, superalloys leverage microstructural innovations like γ/γ′ precipitation hardening and oxide dispersion strengthening (ODS) to combat creep (deformation under stress) and fatigue.

Types of Superalloys

Key Properties

- Exceptional High-Temperature Strength: Maintains integrity at temperatures up to 90% of their melting points.

- Corrosion & Oxidation Resistance: Chromium, aluminum, and rare-earth elements form protective surface layers.

- Creep Resistance: Microstructures resist gradual deformation under prolonged stress.

How Are Superalloys Produced?

Superalloys are known as the “king of metals” because they remain indestructible even under the most extreme conditions – imagine the scorching environment inside a jet engine, where ordinary metals have already melted and deformed, while nickel based superalloys remain in their original state and work stably for tens of thousands of hours.

This material can withstand the triple attacks of high temperature, corrosion, and wear at the same time: chemical pipelines soaked in strong acid for ten years without perforation, aviation turbine blades cutting flames at a speed of tens of thousands of revolutions per minute without deformation, and equipment deep in oil and gas wells is safe and sound surrounded by highly toxic hydrogen sulfide. Huaxiao Metal Supplier has the good quality product in China.

- Raw Material Melting & Refining

- Select high-purity nickel/cobalt-based alloys.

- Vacuum Induction Melting (VIM) removes impurities; Electroslag/Vacuum Arc Remelting (ESR/VAR) enhances purity and structure.

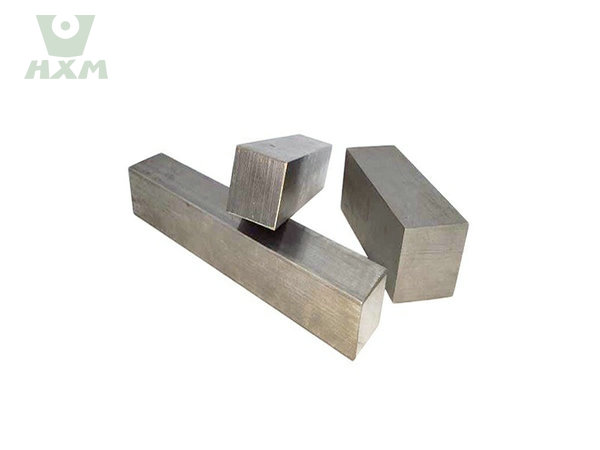

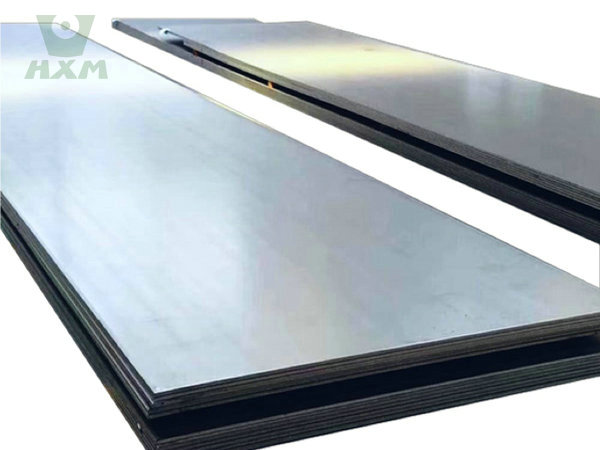

- Precision Shaping

- Cast complex geometries (e.g., turbine blades) via directional solidification or 3D printing.

- Hot forging/rolling refines grain structure for strength.

- Heat Treatment & Finishing

- Solution annealing + aging forms strengthening phases (e.g., γ’ precipitates).

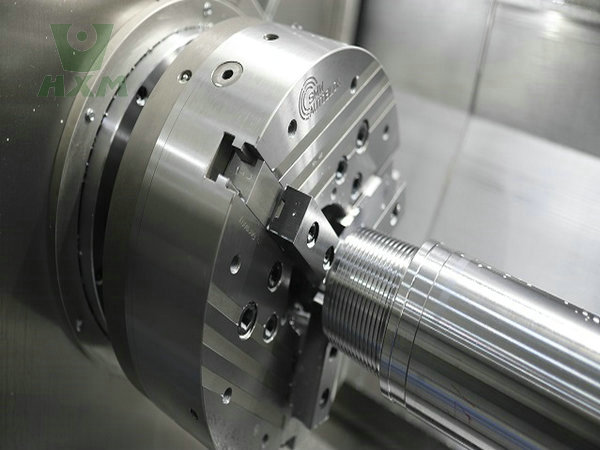

- CNC machining achieves tight tolerances; coatings enhance durability.

- Quality Control

- NDT (X-ray, ultrasonic) ensures defect-free products.

- Certifications (ISO 9001, AS9100) validate performance for aerospace/energy applications.

Applications of Superalloy

Backed by vertically integrated facilities spanning 250,000 m² in industrial hubs like Shanghai, we guarantee mill-direct quality with full traceability, supported by our annual production capacity of 50,000+ tons and real-time inventory of 8,000+ tons for immediate global dispatch. Our commitment to innovation—evidenced by partnerships with leading aerospace, energy, and medical giants—ensures your projects benefit from materials that enhance durability while reducing lifecycle costs by up to 30%, offering not just products but engineered solutions for extreme environments. Superalloy has many function in industries and the properties is good than others.

- Aerospace & Defense

- Turbine Blades: Single-crystal nickel superalloys (e.g., CMSX-4®) enable jet engines to operate at 1,400°C with minimal cooling.

- Rocket Engines: NASA’s GRX-810 (a 3D-printed ODS alloy) withstands 2,000°F+ while doubling strength and durability.

- Space Exploration: Radiation-resistant alloys for spacecraft components.

- Energy Sector

- Gas Turbines: Cobalt-based alloys improve efficiency in power plants.

- Nuclear Reactors: Nickel-chromium superalloys resist irradiation and corrosion.

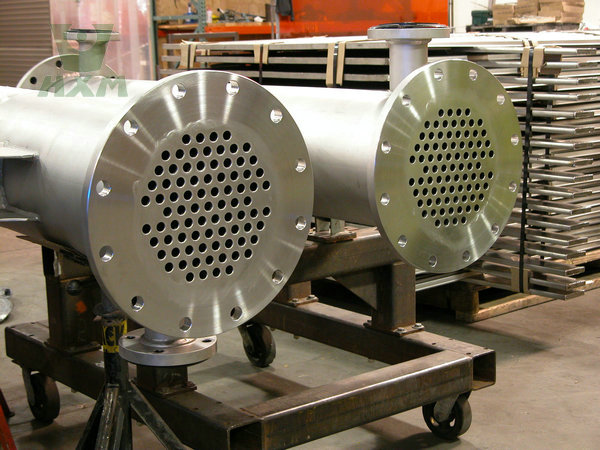

- Chemical & Petrochemical

- Reactor Vessels: Hastelloy® alloys endure acidic and chlorine-rich environments.

- Offshore Drilling: Corrosion-resistant components for harsh marine conditions.

Why Huaxiao Metal Leads the Superalloy Industry?

As a trusted superalloy manufacturer, we combine decades of expertise with cutting-edge technology to deliver unmatched quality and reliability:

- Advanced Manufacturing Capabilities

- Precision Casting: Single-crystal and directionally solidified components for aerospace turbines.

- 3D Printing: Laser-powder bed fusion (LPBF) for complex geometries with minimal material waste.

- ISO-Certified Processes: Rigorous quality control from raw material sourcing to final inspection.

- Stable Supply Chain & Global Reach

- Strategic stockpiles of nickel, cobalt, and rare-earth metals ensure uninterrupted production.

- Logistics networks spanning Asia, Europe, and the Americas guarantee on-time delivery.

- Customized Solutions

- Alloy development tailored to your operational demands (e.g., low-density variants for fuel efficiency).

- Technical support from material selection to post-production testing.

- Sustainability Focus

- Recycling programs for scrap superalloy materials.

- Energy-efficient production processes aligned with net-zero goals.