High Carbon Steel

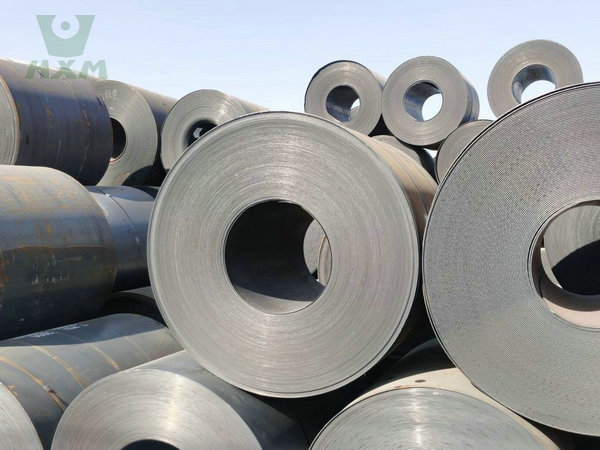

Huaxiao Metals supply high carbon steel in multiple forms and custom sizes:

| Product Form | Thickness/Size Range |

|---|---|

| Steel Sheets/Plates | 1.5mm – 60mm |

| Steel Bars | 10mm – 200mm diameter |

| Steel Coils | Width: 600mm – 1500mm |

| Wire Rods | 5.5mm – 16mm |

| Custom Profiles | Upon request |

Our commitment to excellence is reflected in our numerous certifications, including IATF16949, ISO9001, PED, and ISO14001. As a recognized “high-tech enterprise” with multiple national patents, Huaxiao Metal constantly breaks through the boundaries of metal manufacturing innovation, symbolizing our expanding capabilities and continuous dedication to providing world-class solutions. We place great emphasis on customer satisfaction, providing material consulting, process consulting, and reliable mass production services to meet the diverse needs of global customers.

High Carbon Steel Grade

High carbon steel, defined by its carbon content ranging from 0.60% to 1.70%, is a cornerstone of industrial and tooling applications. Its exceptional hardness, wear resistance, and ability to retain strength at elevated temperatures make it indispensable for cutting tools, springs, and high-stress machinery components. This guide explores the classification, mechanical properties, and applications of key high carbon steel grades. Welcome to contact us.

- ASTM (U.S.) Standards: AISI 1095, AISI 1075, AISI 1060, AISI 1045, AISI 1080, AISI W1-7.

- EN (European) Standards: C70 (1.1520), C80 (1.1525), C100 (1.1545), DIN 1.2842.

- JIS (Japanese) Standards: SK5 (G4401) , SK85, SUP9, SK4 , JIS B 4053 , JIS G 4801, JIS G 4401.

- GB (China) Standard: T10 Steel, GB/T 20566-2006, GB/T 699-2015, GB/T 699, YB/T 4758, SAE 52100.

Common of High Carbon Steel Grade

| Grade | Carbon Content (%) | Key Alloying Elements | Typical Applications |

|---|---|---|---|

| SAE 1095 | 0.90–1.03 | Manganese (0.30–0.50%) | Knives, springs, saw blades, tire cord |

| SAE 52100 | 0.98–1.10 | Chromium (1.30–1.60%) | Bearings, ball screws, high-wear machine parts |

| DIN 1.2842 | 0.90–1.05 | Chromium (0.50%), Molybdenum (0.50%) | Cutting tools, cold work dies, gauge blocks |

| AISI W1-7 | 0.70–0.80 | – | Hand tools, drills, taps |

| AISI 1080 | 0.75–0.88 | – | Automotive springs, agricultural tools |

High carbon metal steel is classified into various grades based on carbon content, alloying elements, and heat treatment. Each grade offers unique properties, making it suitable for specific industrial applications. Huaxiao Metal Supplier has the good quality of high carbon steel and the service is customerized for you. If you want to learn about more details, you can click the button, and our company expert will provide the solution for you within 24 hours.

High Carbon Steel Properties

| Property | Value Range | Comparison with Mild Steel |

|---|---|---|

| Carbon Content | 0.6% – 1.5% | Mild Steel: 0.05% – 0.25% |

| Tensile Strength | 700 – 1,200 MPa | Mild Steel: 400 – 550 MPa |

| Hardness (Rockwell C) | 55 – 65 HRC | Mild Steel: ~20 HRC |

| Wear Resistance | Very High | Moderate in Mild Steel |

| Machinability | Moderate | Easier in Mild Steel |

Advantages of High Carbon Steel

High carbon metal steel’s blend of hardness, wear resistance, and cost efficiency makes it a material of choice for demanding applications. It offers a unique combination of mechanical properties that make it indispensable across industries. Whether you’re manufacturing precision tools or heavy-duty machinery components, high carbon steel delivers the performance edge you need. Welcome to ask for the lastest price by clicking the button.

- Unmatched Hardness and Strength

Mechanical Property: High carbon metal steel achieves a Brinell hardness (HB) of 200–650 and tensile strength of 600–2,000 MPa after heat treatment.

Data Insight: SAE 52100 high carbon steel, widely used in bearings, reaches 64 HRC (Rockwell C scale) after quenching and tempering, surpassing the hardness of many stainless steels.

Application: Ideal for cutting tools, springs, and high-stress components where dimensional stability is critical.

- Superior Wear Resistance

Performance Metric: High carbon metal steel exhibits a Wear Resistance Index of 8.5–9.5/10 (ASTM G65 testing), outperforming medium and low-carbon steels by 30% in abrasive environments.

Case Study: In mining equipment, high carbon alloy steel drill bits last 3x longer than alloy steel alternatives, reducing downtime and maintenance costs.

- Exceptional Edge Retention

Technical Edge: The fine martensitic structure formed during heat treatment ensures sharp edges that resist deformation.

Industry Example: Surgical instruments made from SAE 1095 high carbon alloy steel maintain precision cuts even after 10,000+ cycles in sterile environments.

Why Choose Huaxiao Metal?

Huaxiao Metal Manufacturer was founded in 2014 and is a leading metal manufacturing and casting manufacturer headquartered in Shanghai, southern China. With over a decade of experience, Huaxiao Metal has evolved from a professional steel casting factory to a comprehensive supplier of metal processing solutions, including precision casting, mechanical processing, welding, and more. Our products play a crucial role in industries such as automotive, construction, agriculture, railway, and large-scale equipment manufacturing. We are proud to collaborate with global industry leaders, including several Fortune 500 companies, to ensure that 90% of our high-quality carbon metal products are exported internationally.

- Certifications: Compliance with ASTM, JIS, and DIN standards ensures reliability.

- Customization: Tailored chemistries (e.g., niobium-microalloyed grades) for ultra-fine grain structures.

- Global Support: Technical experts in 15+ countries to optimize your applications.