Precision alloys excel in specialized electromagnetic/thermal applications, while titanium alloys dominate structural lightweighting and corrosive environments. Choose:

Precision alloys for sensors, seals, resistors.

Titanium alloys for aerospace, medical, marine hardware.

Huaxiao Metal Manufacturer provides all kinds of alloy products and the price is suitable and afforrable for you, welcome to inquiry and learn about the more details.

Huaxiao Metal Manufacturer also provides other alloys, such as Hastelloy, Incoloy, Inconel, Monel, Precision Alloy, Titanium Alloy.

Supported Shape Products: Sheets&plates, bars&rods,coils, strips,tubes&pipes,wires&meshes.

This paper will compare Titanium Alloy with the Precision Alloy, which will help you better understand the similarities and differences between the two materials and then choose the alloy that suits your needs.

What Is Precision Alloy?

Precision alloy is a category of materials with special physical properties such as magnetic, electrical, thermal, and optical properties, combined with specific mechanical and chemical properties. Developed in the 1950s, precision alloys have played a crucial role in various high-tech industries, including aerospace, petrochemicals, energy, medical devices, and electronics. These alloys are not primarily used as structural components but are essential for their unique physical properties, which enable them to perform critical functions in precision instruments, sensors, actuators, and other advanced applications.

| Alloy Type | Representative Grades | Key Property | Standard |

|---|---|---|---|

| Soft Magnetic | 1J22, 1J50, 1J79 | High μ/Bs | ASTM A753 |

| Low Expansion | 4J36 (Invar), 4J29 (Kovar) | Near-zero CTE | ASTM F15 |

| Resistance | 6J10 (Manganin), 6J20 | Stable TCR | IEC 60468 |

| Elastic | 3J21, 3J53 | Constant modulus | GB/T 15018 |

Precision alloys encompass a wide range of materials, each designed for specific applications. Common types include:

- Elastic Alloys: Such as 3J21 (Co40NiCrMo), known for its high elasticity, corrosion resistance, and ability to withstand hydrogen sulfide corrosion. It is widely used in precision springs, membranes, and other elastic elements in environments up to 400°C.

- Magnetic Alloys: Including soft magnetic alloys like Permalloy (Fe-Ni) and hard magnetic alloys such as Sm-Co and Nd-Fe-B, which are used in transformers, motors, magnets, and magnetic storage devices.

- Expansion Alloys: Like Invar (36Ni-Fe) and Kovar (29Ni17CoFe), which exhibit minimal thermal expansion and are used in glass-to-metal seals and precision measuring instruments.

- High-Temperature Alloys: Such as Inconel and Hastelloy, which maintain strength and corrosion resistance at elevated temperatures, making them ideal for aerospace and petrochemical applications.

Chemical Composition

| Element | 1J50 | 4J29 | 6J10 | 3J21 |

|---|---|---|---|---|

| Ni | 49-51 | 28-29 | – | 35-37 |

| Fe | Bal. | Bal. | – | Bal. |

| Co | ≤0.2 | 16-17 | – | 12-14 |

| Cu | – | – | 84-86 | – |

| Mn | 0.3-0.6 | – | 11-13 | – |

| Cr | – | – | – | 19-21 |

Critical Notes:

Ni-Fe alloys dominate soft magnetic/low expansion categories

Cu-Mn-Ni systems preferred for resistance alloys

For a complete list of our stock items, please contact us or fill out our online quote form.

Physical properties

| Property | 1J50 | 4J29 | 6J10 |

|---|---|---|---|

| Density (g/cm³) | 8.25 | 8.36 | 8.40 |

| CTE (10⁻⁶/°C) | 9.5 | 4.9 | 18.0 |

| ρ (μΩ·m) | 0.45 | 0.49 | 0.43 |

| Thermal Cond. (W/m·K) | 29.5 | 17.3 | 22.0 |

Performance Comparison:

| Alloy | Best For | Limitation |

|---|---|---|

| 1J50 | AC sensors | Moderate Bs |

| 4J29 | Glass seals | Poor ductility |

| 6J10 | Shunt resistors | Low strength |

Mechanical properties

The mechanical properties of precision alloys are crucial for their performance in various applications:

- Tensile Strength: 3J21 can achieve a tensile strength of up to 2950 MPa after cold working and aging, making it suitable for high-stress applications.

- Hardness: The hardness of 3J21 can be tailored through heat treatment, with values ranging from 40-50 HRC, depending on the desired balance between strength and ductility.

- Fatigue Life: Precision alloys often exhibit high fatigue life, making them suitable for applications involving cyclic loading, such as springs and bearings.

For a complete list of our stock items, please contact us or fill out our online quote form.

Welcome to Huaxiao Metal Manufacturer to request the price, trust you can be satisfied in the alloy products. Our company has the good service and the quality has the assurance in China.

What Is Titanium Alloy?

Titanium alloys are high-performance metallic materials renowned for their exceptional strength-to-weight ratio, corrosion resistance, and biocompatibility. These alloys are classified into alpha (α), beta (β), and alpha-beta (α-β) categories, each offering distinct advantages for aerospace, medical, marine, and industrial applications.

Key Characteristics:

✔ High strength-to-weight ratio (up to 1,400 MPa tensile strength)

✔ Outstanding corrosion resistance (seawater, chlorine, acids)

✔ Biocompatible (ideal for medical implants)

✔ Excellent fatigue and creep resistance

✔ High-temperature stability (up to 600°C for some grades)

| Grade | Type | Standard | Key Features |

|---|---|---|---|

| Ti-6Al-4V (Grade 5) | α-β | ASTM B348, AMS 4928 | Most widely used, aerospace/medical |

| Ti-6Al-4V ELI | α-β | ASTM F136 | Extra-low interstitial, medical implants |

| Ti-3Al-2.5V (Grade 9) | Near-α | ASTM B338 | High ductility, hydraulic systems |

| Ti-10V-2Fe-3Al | β | AMS 4986 | High strength, landing gear |

| CP Titanium (Grade 2) | α | ASTM B265 | Excellent corrosion resistance |

Chemical Composition

| Element | Ti-6Al-4V | Ti-6Al-4V ELI | Ti-3Al-2.5V | CP Ti (Grade 2) |

|---|---|---|---|---|

| Ti | Balance | Balance | Balance | ≥99.2 |

| Al | 5.5-6.75 | 5.5-6.5 | 2.5-3.5 | – |

| V | 3.5-4.5 | 3.5-4.5 | 2.0-3.0 | – |

| Fe | ≤0.30 | ≤0.25 | ≤0.25 | ≤0.30 |

| O | ≤0.20 | ≤0.13 | ≤0.15 | ≤0.25 |

Key Notes:

Aluminum (Al) stabilizes α-phase (enhances strength)

Vanadium (V) promotes β-phase (improves ductility)

Low interstitials (O, N, C) in ELI grades for medical use

Physical properties

| Property | Ti-6Al-4V | CP Ti (Grade 2) | Ti-10V-2Fe-3Al |

|---|---|---|---|

| Density (g/cm³) | 4.43 | 4.51 | 4.65 |

| Melting Point (°C) | 1604-1660 | 1668 | 1650 |

| Thermal Conductivity (W/m·K) | 6.7 | 16.4 | 7.2 |

| Electrical Resistivity (μΩ·m) | 1.78 | 0.52 | 1.85 |

| CTE (10⁻⁶/°C, 20-100°C) | 8.6 | 8.9 | 9.2 |

Comparison with Competing Materials:

| Property | Ti-6Al-4V | Stainless 316 | Aluminum 7075 |

|---|---|---|---|

| Strength-to-Weight | Excellent | Good | Very Good |

| Corrosion Resistance | Superior | Good | Poor |

| Cost Factor | $$$ | $$ | $ |

Our company has the customerized solutions for every customers about hastelloy Metal problems. The exberts will freely answer your questions. For a complete list of our stock items, please contact us or fill out our online quote form.

Mechanical properties

| Grade | Tensile (MPa) | Yield (MPa) | Elongation (%) | Hardness (HV) |

|---|---|---|---|---|

| Ti-6Al-4V | 895-930 | 825-869 | 10-15 | 330-360 |

| Ti-6Al-4V ELI | 860-900 | 795-828 | 12-16 | 310-340 |

| CP Ti (Grade 2) | 345-483 | 275-345 | 20-25 | 160-200 |

| Ti-10V-2Fe-3Al | 1000-1200 | 900-1100 | 6-10 | 350-400 |

Fatigue & Fracture Toughness:

Ti-6Al-4V: Fatigue limit ~500 MPa (10⁷ cycles)

Ti-6Al-4V ELI: Higher fracture toughness (KIC ~70 MPa√m)

Huaxiao Metal Manufacturer is the top of processing hastelloy alloy in China, and the products are all premium in using and purchasing. For a complete list of our stock items, please contact us or fill out our online quote form.

Precision Alloy Vs Titanium Alloy Cost Considerations

The cost-effectiveness of precision alloys depends on several factors:

| Factor | Impact on Cost | Mitigation |

|---|---|---|

| Ni/Co content | +30-50% | Monitor LME prices |

| Tolerance | ±0.01mm adds 25% | Relax where possible |

| Testing | Certification adds 15% | Group testing |

Price Ranges (2024):

Standard grades: $50-100/kg

High-precision: $200-500/kg

| Product Form | Ti-6Al-4V (USD/kg) | CP Ti (Grade 2) (USD/kg) |

|---|---|---|

| Bar Stock | $80-120 | $50-80 |

| Sheet (1mm) | $150-200 | $100-150 |

| Forgings | $200-300 | – |

| Powder (AM) | $300-500 | – |

Procurement Tips:

✔ Bulk orders (>500kg) reduce costs by 10-20%

✔ Consider remelted grades for non-critical applications

✔ Verify AMS/MIL specs for aerospace components

Special processes required:

Hydrogen annealing for magnetic alloys

Precision cold rolling (≥99.9% thickness uniformity)

Laser cutting for complex shapes

- Heat Treatment: Heat treatment processes, such as annealing, quenching, and tempering, are employed to optimize the mechanical properties and physical characteristics of the alloy.

Cost Structure:

60% raw materials

25% processing

15% QC/testing

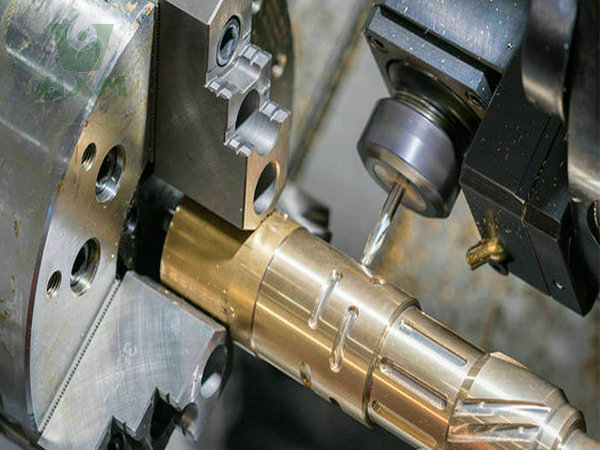

Machining:

Use carbide tools with high-pressure coolant

Low cutting speeds (30-60 m/min)

Welding:

GTAW (TIG) with argon shielding

EBW for high-precision joints

Additive Manufacturing:

Ti-6Al-4V powder (15-45μm) for DMLS/SLM

Cost Drivers:

Sponge titanium production (Kroll process)

Vacuum arc remelting (VAR) for premium grades

Precision machining (up to 40% of part cost)

Pricing Trends

Nickel-based alloys: 8-12% annual volatility

Cobalt-containing grades: $5-10/kg price swings monthly

Market shifts: EV demand increasing 1Jxx series prices

- Expansion Alloys: Invar and Kovar alloys typically cost between 30and100 per pound (approximately 66to220 per kilogram).

Pricing Insights

Market Price Factors:

Titanium sponge prices (~$8-12/kg)

Aerospace demand cycles

China’s production capacity (60% of global supply)

Price Trends:

5-8% annual increase (2020-2024)

AM powders commanding 200-300% premium

If you have any purchase needs, please feel free to contact us.

Huaxiao Metal Manufacturer has the cheap price and the good services in alloy products, and our company provides the customerized vip service for the customers, our delivery is fast and has assurrance.

For a complete list of our stock items, please contact us or fill out our online quote form.

Precision Alloy Vs Titanium Alloy Advantages

- Enhanced Performance: The unique properties of precision alloys enable devices to operate more efficiently and reliably, improving overall system performance.

- Reduced Size and Weight: High-strength and low-density alloys, such as titanium-based precision alloys, allow for the design of lighter and more compact components.

- Corrosion Resistance: Alloys like Inconel and Hastelloy provide excellent corrosion resistance, extending the lifespan of components in harsh environments.

- Thermal Stability: High-temperature alloys maintain their properties at elevated temperatures, making them suitable for aerospace and energy applications.

- High Strength-to-Weight Ratio: Titanium alloys offer superior strength compared to many other metals at a significantly lower weight, making them ideal for aerospace applications.

- Excellent Corrosion Resistance: Titanium’s ability to form a protective oxide layer in harsh environments ensures long-term durability in marine and chemical processing industries.

- Biocompatibility: Titanium alloys are widely used in medical implants due to their non-toxic, non-allergenic, and non-carcinogenic properties.

- High-Temperature Performance: Alloys like Ti-5Al-2.5Sn retain their strength at elevated temperatures, making them suitable for aerospace engine components.

Precision Alloy Vs Titanium Alloy Applications

Applications of Precision Alloy:

| Aerospace | High-strength, corrosion-resistant alloys for engine parts, landing gear, etc. |

| Electronics | Conductive, stable alloys for connectors, leads, and components. |

| Medical | Biocompatible, durable alloys for surgical tools, implants, and prosthetics. |

| Automotive | High-performance alloys for engine, transmission, and suspension components. |

| Precision Instruments | Accurate, stable alloys for measuring tools and gauges. |

| Nuclear Industry | Radiation-resistant, corrosion-proof alloys for reactor parts and fuel rods. |

Applications of Titanium Alloy:

| Industry | Component | Alloy Choice | Why Titanium? |

|---|---|---|---|

| Aerospace | Jet engine fan blades | Ti-6Al-4V | High temp strength |

| Medical | Hip implants | Ti-6Al-4V ELI | Osseointegration |

| Marine | Submarine hulls | Grade 5 | Seawater resistance |

| Automotive | Connecting rods | Ti-10V-2Fe-3Al | Weight reduction |

| Chemical | Heat exchangers | Grade 2 | Acid resistance |

In Conclusion

Huaxiao Metal Supplier has the various alloy products for sale online Precision alloys are a cornerstone of modern industrial applications, offering unmatched corrosion resistance, high-temperature stability, and mechanical strength. While they come at a higher cost compared to materials like stainless steel, their performance in extreme environments justifies the investment. By understanding their chemical composition, physical and mechanical properties, and cost considerations, industries can optimize their use of Hastelloy alloys for long-lasting and reliable performance. If you have any purchase needs, please feel free to contact us.

Precision alloys enable critical technological advancements through:

✔ Exact property control (CTE, μ, ρ)

✔ Superior performance/reliability balance

✔ Custom engineering solutions

Selection Guide:

Magnetic applications: 1J series

Dimensional stability: 4J series

Resistance needs: 6J series

Titanium alloys offer a unique combination of properties that make them indispensable in modern industry. By understanding their chemical composition, physical and mechanical properties, and applications, you can make informed decisions when selecting and procuring titanium alloys for your projects. With advancements in manufacturing technology and a focus on cost-effectiveness, titanium alloys are poised to play an even greater role in shaping the future of various industries.

Huaxiao Metal Manufacturer provides all kinds of alloy products and the price is suitable and afforrable for you, welcome to inquiry and learn about the more details.

Huaxiao Metal Manufacturer also provides other alloys, such as Hastelloy, Incoloy, Inconel, Monel, Precision Alloy, Titanium Alloy.

Supported Shape Products: Sheets&plates, bars&rods,coils, strips,tubes&pipes,wires&meshes.

This paper will compare Titanium Alloy with the Precision Alloy, which will help you better understand the similarities and differences between the two materials and then choose the alloy that suits your needs.

What Is Precision Alloy?

Precision alloy is a category of materials with special physical properties such as magnetic, electrical, thermal, and optical properties, combined with specific mechanical and chemical properties. Developed in the 1950s, precision alloys have played a crucial role in various high-tech industries, including aerospace, petrochemicals, energy, medical devices, and electronics. These alloys are not primarily used as structural components but are essential for their unique physical properties, which enable them to perform critical functions in precision instruments, sensors, actuators, and other advanced applications.

| Alloy Type | Representative Grades | Key Property | Standard |

|---|---|---|---|

| Soft Magnetic | 1J22, 1J50, 1J79 | High μ/Bs | ASTM A753 |

| Low Expansion | 4J36 (Invar), 4J29 (Kovar) | Near-zero CTE | ASTM F15 |

| Resistance | 6J10 (Manganin), 6J20 | Stable TCR | IEC 60468 |

| Elastic | 3J21, 3J53 | Constant modulus | GB/T 15018 |

Precision alloys encompass a wide range of materials, each designed for specific applications. Common types include:

- Elastic Alloys: Such as 3J21 (Co40NiCrMo), known for its high elasticity, corrosion resistance, and ability to withstand hydrogen sulfide corrosion. It is widely used in precision springs, membranes, and other elastic elements in environments up to 400°C.

- Magnetic Alloys: Including soft magnetic alloys like Permalloy (Fe-Ni) and hard magnetic alloys such as Sm-Co and Nd-Fe-B, which are used in transformers, motors, magnets, and magnetic storage devices.

- Expansion Alloys: Like Invar (36Ni-Fe) and Kovar (29Ni17CoFe), which exhibit minimal thermal expansion and are used in glass-to-metal seals and precision measuring instruments.

- High-Temperature Alloys: Such as Inconel and Hastelloy, which maintain strength and corrosion resistance at elevated temperatures, making them ideal for aerospace and petrochemical applications.

Chemical Composition

| Element | 1J50 | 4J29 | 6J10 | 3J21 |

|---|---|---|---|---|

| Ni | 49-51 | 28-29 | – | 35-37 |

| Fe | Bal. | Bal. | – | Bal. |

| Co | ≤0.2 | 16-17 | – | 12-14 |

| Cu | – | – | 84-86 | – |

| Mn | 0.3-0.6 | – | 11-13 | – |

| Cr | – | – | – | 19-21 |

Critical Notes:

Ni-Fe alloys dominate soft magnetic/low expansion categories

Cu-Mn-Ni systems preferred for resistance alloys

For a complete list of our stock items, please contact us or fill out our online quote form.

Physical properties

| Property | 1J50 | 4J29 | 6J10 |

|---|---|---|---|

| Density (g/cm³) | 8.25 | 8.36 | 8.40 |

| CTE (10⁻⁶/°C) | 9.5 | 4.9 | 18.0 |

| ρ (μΩ·m) | 0.45 | 0.49 | 0.43 |

| Thermal Cond. (W/m·K) | 29.5 | 17.3 | 22.0 |

Performance Comparison:

| Alloy | Best For | Limitation |

|---|---|---|

| 1J50 | AC sensors | Moderate Bs |

| 4J29 | Glass seals | Poor ductility |

| 6J10 | Shunt resistors | Low strength |

Mechanical properties

Welcome to Huaxiao Metal Manufacturer to request the price, trust you can be satisfied in the alloy products. Our company has the good service and the quality has the assurance in China.

For a complete list of our stock items, please contact us or fill out our online quote form.

What Is Titanium Alloy?

Titanium alloys are high-performance metallic materials renowned for their exceptional strength-to-weight ratio, corrosion resistance, and biocompatibility. These alloys are classified into alpha (α), beta (β), and alpha-beta (α-β) categories, each offering distinct advantages for aerospace, medical, marine, and industrial applications.

Key Characteristics:

✔ High strength-to-weight ratio (up to 1,400 MPa tensile strength)

✔ Outstanding corrosion resistance (seawater, chlorine, acids)

✔ Biocompatible (ideal for medical implants)

✔ Excellent fatigue and creep resistance

✔ High-temperature stability (up to 600°C for some grades)

| Grade | Type | Standard | Key Features |

|---|---|---|---|

| Ti-6Al-4V (Grade 5) | α-β | ASTM B348, AMS 4928 | Most widely used, aerospace/medical |

| Ti-6Al-4V ELI | α-β | ASTM F136 | Extra-low interstitial, medical implants |

| Ti-3Al-2.5V (Grade 9) | Near-α | ASTM B338 | High ductility, hydraulic systems |

| Ti-10V-2Fe-3Al | β | AMS 4986 | High strength, landing gear |

| CP Titanium (Grade 2) | α | ASTM B265 | Excellent corrosion resistance |

Chemical Composition

| Element | Ti-6Al-4V | Ti-6Al-4V ELI | Ti-3Al-2.5V | CP Ti (Grade 2) |

|---|---|---|---|---|

| Ti | Balance | Balance | Balance | ≥99.2 |

| Al | 5.5-6.75 | 5.5-6.5 | 2.5-3.5 | – |

| V | 3.5-4.5 | 3.5-4.5 | 2.0-3.0 | – |

| Fe | ≤0.30 | ≤0.25 | ≤0.25 | ≤0.30 |

| O | ≤0.20 | ≤0.13 | ≤0.15 | ≤0.25 |

Key Notes:

Aluminum (Al) stabilizes α-phase (enhances strength)

Vanadium (V) promotes β-phase (improves ductility)

Low interstitials (O, N, C) in ELI grades for medical use

Physical properties

| Property | Ti-6Al-4V | CP Ti (Grade 2) | Ti-10V-2Fe-3Al |

|---|---|---|---|

| Density (g/cm³) | 4.43 | 4.51 | 4.65 |

| Melting Point (°C) | 1604-1660 | 1668 | 1650 |

| Thermal Conductivity (W/m·K) | 6.7 | 16.4 | 7.2 |

| Electrical Resistivity (μΩ·m) | 1.78 | 0.52 | 1.85 |

| CTE (10⁻⁶/°C, 20-100°C) | 8.6 | 8.9 | 9.2 |

Comparison with Competing Materials:

| Property | Ti-6Al-4V | Stainless 316 | Aluminum 7075 |

|---|---|---|---|

| Strength-to-Weight | Excellent | Good | Very Good |

| Corrosion Resistance | Superior | Good | Poor |

| Cost Factor | $$$ | $$ | $ |

Our company has the customerized solutions for every customers about hastelloy Metal problems. The exberts will freely answer your questions. For a complete list of our stock items, please contact us or fill out our online quote form.

Mechanical properties

| Grade | Tensile (MPa) | Yield (MPa) | Elongation (%) | Hardness (HV) |

|---|---|---|---|---|

| Ti-6Al-4V | 895-930 | 825-869 | 10-15 | 330-360 |

| Ti-6Al-4V ELI | 860-900 | 795-828 | 12-16 | 310-340 |

| CP Ti (Grade 2) | 345-483 | 275-345 | 20-25 | 160-200 |

| Ti-10V-2Fe-3Al | 1000-1200 | 900-1100 | 6-10 | 350-400 |

Fatigue & Fracture Toughness:

Ti-6Al-4V: Fatigue limit ~500 MPa (10⁷ cycles)

Ti-6Al-4V ELI: Higher fracture toughness (KIC ~70 MPa√m)

Huaxiao Metal Manufacturer is the top of processing hastelloy alloy in China, and the products are all premium in using and purchasing. For a complete list of our stock items, please contact us or fill out our online quote form.

Precision Alloy Vs Titanium Alloy Cost Considerations

The cost-effectiveness of precision alloys depends on several factors:

| Factor | Impact on Cost | Mitigation |

|---|---|---|

| Ni/Co content | +30-50% | Monitor LME prices |

| Tolerance | ±0.01mm adds 25% | Relax where possible |

| Testing | Certification adds 15% | Group testing |

Price Ranges (2024):

Standard grades: $50-100/kg

High-precision: $200-500/kg

| Product Form | Ti-6Al-4V (USD/kg) | CP Ti (Grade 2) (USD/kg) |

|---|---|---|

| Bar Stock | $80-120 | $50-80 |

| Sheet (1mm) | $150-200 | $100-150 |

| Forgings | $200-300 | – |

| Powder (AM) | $300-500 | – |

Procurement Tips:

✔ Bulk orders (>500kg) reduce costs by 10-20%

✔ Consider remelted grades for non-critical applications

✔ Verify AMS/MIL specs for aerospace components

Special processes required:

Hydrogen annealing for magnetic alloys

Precision cold rolling (≥99.9% thickness uniformity)

Laser cutting for complex shapes

- Heat Treatment: Heat treatment processes, such as annealing, quenching, and tempering, are employed to optimize the mechanical properties and physical characteristics of the alloy.

Cost Structure:

60% raw materials

25% processing

15% QC/testing

Machining:

Use carbide tools with high-pressure coolant

Low cutting speeds (30-60 m/min)

Welding:

GTAW (TIG) with argon shielding

EBW for high-precision joints

Additive Manufacturing:

Ti-6Al-4V powder (15-45μm) for DMLS/SLM

Cost Drivers:

Sponge titanium production (Kroll process)

Vacuum arc remelting (VAR) for premium grades

Precision machining (up to 40% of part cost)

Pricing Trends

Nickel-based alloys: 8-12% annual volatility

Cobalt-containing grades: $5-10/kg price swings monthly

Market shifts: EV demand increasing 1Jxx series prices

- Expansion Alloys: Invar and Kovar alloys typically cost between 30and100 per pound (approximately 66to220 per kilogram).

Pricing Insights

Market Price Factors:

Titanium sponge prices (~$8-12/kg)

Aerospace demand cycles

China’s production capacity (60% of global supply)

Price Trends:

5-8% annual increase (2020-2024)

AM powders commanding 200-300% premium

If you have any purchase needs, please feel free to contact us.

Huaxiao Metal Manufacturer has the cheap price and the good services in alloy products, and our company provides the customerized vip service for the customers, our delivery is fast and has assurrance.

For a complete list of our stock items, please contact us or fill out our online quote form.

Precision Alloy Vs Titanium Alloy Advantages

- Enhanced Performance: The unique properties of precision alloys enable devices to operate more efficiently and reliably, improving overall system performance.

- Reduced Size and Weight: High-strength and low-density alloys, such as titanium-based precision alloys, allow for the design of lighter and more compact components.

- Corrosion Resistance: Alloys like Inconel and Hastelloy provide excellent corrosion resistance, extending the lifespan of components in harsh environments.

- Thermal Stability: High-temperature alloys maintain their properties at elevated temperatures, making them suitable for aerospace and energy applications.

- High Strength-to-Weight Ratio: Titanium alloys offer superior strength compared to many other metals at a significantly lower weight, making them ideal for aerospace applications.

- Excellent Corrosion Resistance: Titanium’s ability to form a protective oxide layer in harsh environments ensures long-term durability in marine and chemical processing industries.

- Biocompatibility: Titanium alloys are widely used in medical implants due to their non-toxic, non-allergenic, and non-carcinogenic properties.

- High-Temperature Performance: Alloys like Ti-5Al-2.5Sn retain their strength at elevated temperatures, making them suitable for aerospace engine components.

Precision Alloy Vs Titanium Alloy Applications

Applications of Precision Alloy:

| Aerospace | High-strength, corrosion-resistant alloys for engine parts, landing gear, etc. |

| Electronics | Conductive, stable alloys for connectors, leads, and components. |

| Medical | Biocompatible, durable alloys for surgical tools, implants, and prosthetics. |

| Automotive | High-performance alloys for engine, transmission, and suspension components. |

| Precision Instruments | Accurate, stable alloys for measuring tools and gauges. |

| Nuclear Industry | Radiation-resistant, corrosion-proof alloys for reactor parts and fuel rods. |

Applications of Titanium Alloy:

| Industry | Component | Alloy Choice | Why Titanium? |

|---|---|---|---|

| Aerospace | Jet engine fan blades | Ti-6Al-4V | High temp strength |

| Medical | Hip implants | Ti-6Al-4V ELI | Osseointegration |

| Marine | Submarine hulls | Grade 5 | Seawater resistance |

| Automotive | Connecting rods | Ti-10V-2Fe-3Al | Weight reduction |

| Chemical | Heat exchangers | Grade 2 | Acid resistance |

In Conclusion

Huaxiao Metal Supplier has the various alloy products for sale online Precision alloys are a cornerstone of modern industrial applications, offering unmatched corrosion resistance, high-temperature stability, and mechanical strength. While they come at a higher cost compared to materials like stainless steel, their performance in extreme environments justifies the investment. By understanding their chemical composition, physical and mechanical properties, and cost considerations, industries can optimize their use of Hastelloy alloys for long-lasting and reliable performance. If you have any purchase needs, please feel free to contact us.

Precision alloys enable critical technological advancements through:

✔ Exact property control (CTE, μ, ρ)

✔ Superior performance/reliability balance

✔ Custom engineering solutions

Selection Guide:

Magnetic applications: 1J series

Dimensional stability: 4J series

Resistance needs: 6J series

Titanium alloys offer a unique combination of properties that make them indispensable in modern industry. By understanding their chemical composition, physical and mechanical properties, and applications, you can make informed decisions when selecting and procuring titanium alloys for your projects. With advancements in manufacturing technology and a focus on cost-effectiveness, titanium alloys are poised to play an even greater role in shaping the future of various industries.