Hastelloy Alloy Pipe & Tube, please note that the above table provides a range of standard thicknesses, widths, and lengths for Hastelloy.

- Dimensions:

- Outside Diameter: Φ3 – Φ600mm

- Wall Thickness: 0.5 – 30mm

- Length: ≤ 12000mm

- Shapes: Angle, Hexagon, Square, Channel, Round,etc.

- *Customized size needs to be confirmed with us

- Grades: X, B, B-2, B-3, C, C-4, C-22, C-22HS, C-276, C-20000, G-3, G-30, G-35, N, S.

Hastelloy Alloy Pipe Size And Specifications

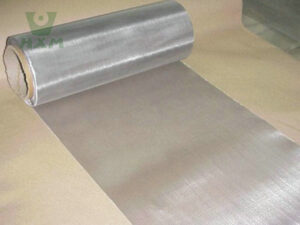

Please note that the specifications and sizes provided in the table are general guidelines and can vary based on manufacturer and custom requirements. For precise dimensions and detailed specifications, it is recommended to consult the relevant standards and manufacturer’s documentation. Similar detailed specifications for other Hastelloy alloys may not be listed here but can be obtained from the respective standards or manufacturers.Huaxiao Metal Supplier also has other shapes hastelloy alloy, such as bar, coil, strip, sheet&plate, wire&mesh.

| Specification | ASTM B622 / ASTM B619 | Alloy B-2 UNS N10665 |

|---|---|---|

| Seamless Pipe Sizes | ||

| Outer Diameter (OD) | 4 to 219 mm | 5.0 to 203.2 mm (custom sizes) |

| Wall Thickness (WT) | 0.5 to 20 mm | As per requirement |

| Length | Up to 6 meters | Up to 6 meters |

| Welded Pipe Sizes | ||

| Outer Diameter (OD) | 5.0 to 1219.2 mm | 5.0 to 1219.2 mm (in stock + custom sizes) |

| Wall Thickness (WT) | – | 1.0 to 15.0 mm |

| Length | Up to 6 meters | Up to 6 meters |

| Pipe Schedules | SCH5, SCH10, SCH40, STD, SCH80, SCH160 | – |

| Pipe Conditions | Hot-Finished, Annealed, Cold-Drawn, Polished, AP (Annealed & Pickled), BA (Bright & Annealed), MF | – |

| Pipe Forms | Square, Rectangular, Round, Hollow, Straight, Hydraulic | – |

| Pipe Ends | Plain End, Beveled End, Threaded | Single Random, Double Random & Cut Length |

| Marking | Standard, Grade, OD, Thickness, Length, Heat No. (or according to customer’s request) | – |

Of course, our company also has other materials and shapes of Hastelloy alloy. As a leading alloy supplier in China, our alloys have quality assurance and quality inspection certificates, and our company provides customized services for every customer. If you have any alloy needs, please feel free to contact us, and our experts will provide you with professional solutions and reasonable plans. You can click any green button on this page to quickly get a quote, and we will reply to you within 24 hours. Looking forward to your inquiry.

Hastelloy Alloy Pipe Advantages

Hastelloy alloys are formulated to withstand a wide array of corrosive environments. They can resist strong acids like sulfuric and hydrochloric acids, as well as oxidizing and reducing agents. This resistance prevents pipe degradation, reducing the risk of leaks and ensuring the safe transport of corrosive fluids. For instance, in chemical processing plants, these pipes can handle aggressive chemicals without succumbing to pitting or crevice corrosion, extending their service life significantly. Welcome to inquiy and ask for the lastest price.

Excellent Corrosion Resistance:

- Hastelloy alloy pipes possess outstanding corrosion resistance in a wide range of environments, including high-temperature and high-pressure conditions.

- They are particularly resistant to corrosive media such as acids, alkalis, and salt solutions, making them suitable for applications in harsh industrial settings.

High Strength and Durability:

- These pipes exhibit high tensile strength and yield strength, ensuring they can withstand significant mechanical stress and pressure.

- Their durability ensures long-term performance and reliability, reducing the need for frequent replacements or repairs.

You can click this button to fill in the basic information of this form. If you have any questions, you can describe them in detail. Our experts will provide you with customized solutions. As a leading metal trading wholesaler in China, we will provide the best metals and services to our customers.

Good Thermal Stability:

- Hastelloy alloy pipes maintain their mechanical properties and corrosion resistance over a wide temperature range, making them suitable for high-temperature applications.

- They can withstand extreme temperature fluctuations without experiencing significant degradation in performance.

Versatility in Applications:

- Due to their excellent corrosion resistance, high strength, and thermal stability, Hastelloy alloy pipes are versatile and can be used in various industries, including chemical processing, petroleum refining, pulp and paper production, and power generation.

- They can be tailored to meet specific application requirements through customization in size, shape, and thickness.

Ease of Fabrication and Installation:

- Hastelloy alloy pipes can be easily fabricated into various shapes and sizes using welding, bending, and forming processes. Their installation process is straightforward, and they can be connected to other piping systems using standard fittings and connections.

Hastelloy Alloy Pipe Applications

Hastelloy alloy pipes have found extensive applications across multiple industries due to their unique set of properties. In the chemical and petrochemical sector, these pipes are indispensable for handling highly reactive and corrosive substances. Their excellent corrosion resistance and high – pressure tolerance make them ideal for critical components like reactors, distillation columns, and acid transfer lines.

- Chemical Processing Industry:

- Hastelloy alloy pipes are ideal for transporting corrosive chemicals and acids in chemical processing plants.

- They can withstand the harsh environments created by these chemicals, ensuring safe and efficient operation of the process equipment.

- Petroleum and Natural Gas Industry:

- In the upstream and downstream sectors of the petroleum and natural gas industry, Hastelloy alloy pipes are used for transporting hydrocarbons and other related fluids.

- Their corrosion resistance and high strength make them suitable for high-pressure and high-temperature applications in this industry.

You can click this button to fill in the basic information of this form. If you have any questions, you can describe them in detail. Our experts will provide you with customized solutions. As a leading metal trading wholesaler in China, we will provide the best metals and services to our customers.

| Industry | Specific Applications | Key Requirements Met by Hastelloy Alloy Pipes |

|---|---|---|

| Chemical and Petrochemical | – Reactors and Vessels Internal Piping: Used to transport reactive and corrosive chemicals within reactors and storage vessels. – Distillation Columns: For the separation of complex chemical mixtures under high – pressure and corrosive conditions. – Acid Transfer Lines: Handling strong acids such as sulfuric acid and hydrochloric acid during production processes. | – Corrosion Resistance: Withstands a wide range of aggressive chemicals, preventing pipe degradation and leaks. – High – Pressure Tolerance: Can handle the high pressures encountered in chemical processing operations. |

| Aerospace | – Jet Engine Components: Used in the fuel and lubrication systems of jet engines, where high – temperature and corrosive environments exist. – Aircraft Hydraulic Systems: Transmitting hydraulic fluids under varying temperatures and pressures. – Spacecraft Thermal Control Systems: Managing the transfer of heat – transfer fluids in extreme space conditions. | – High – Temperature Strength: Maintains integrity at elevated temperatures encountered in aerospace applications. – Lightweight yet Durable: Balances the need for strength with the requirement of reducing overall aircraft weight. |

| Power Generation | – Boiler Feedwater Piping: Transporting feedwater to boilers under high – pressure and high – temperature conditions. – Steam Turbine Piping: Carrying high – pressure steam for power generation. – Flue Gas Desulfurization Systems: Handling the corrosive flue gases produced during power generation. | – Thermal Stability: Resists oxidation and scaling at high temperatures in power plants. – Corrosion Resistance in Flue Gases: Withstands the corrosive effects of sulfur – containing flue gases. |

| Pharmaceutical | – Bioreactor Piping: Used in the production of pharmaceuticals to transport biological fluids and chemical reagents. – Sterile Fluid Transfer Lines: Ensuring the safe and contamination – free transfer of sterile fluids during drug manufacturing. – Waste Treatment Systems: Handling the waste fluids generated during pharmaceutical production. | – Cleanability and Non – Reactivity: Easy to clean and does not react with pharmaceutical substances, maintaining product purity. – Corrosion Resistance to Chemicals: Withstands the various chemicals used in pharmaceutical processes. |

You ask, we answer

We can provide small hastelloy alloy pipe samples for you to check the quality. The sample is free, you only need to pay the shipping cost.

Hastelloy pipe source typically refers to specialized metal manufacturers or suppliers who produce high-quality, corrosion-resistant Hastelloy alloy pipes for use in various industrial applications.

Hastelloy C276 alloy is a nickel-based superalloy with exceptional corrosion resistance, high temperature strength, and durability, making it ideal for a wide range of industrial applications.

Hastelloy B3 alloy stands out due to its exceptional corrosion resistance, enhanced thermal stability, improved weldability, superior physical properties, and versatile applications. These advantages make it a preferred material for various demanding industrial applications.