Applications

Alloy products are indispensable across numerous industries. In aerospace, they offer lightweight yet robust materials crucial for aircraft efficiency and safety. The automotive sector benefits from alloys that enhance fuel efficiency and structural integrity. The welding industry relies on alloys for their strength, corrosion resistance, and adaptability to various welding processes. Additionally, alloys are utilized in electronics, medical devices, and construction, contributing to advancements in technology, healthcare, and infrastructure. Their diverse applications demonstrate alloys’ versatility and importance in modern industry. Huaxiao Metal Manufacturer is professional and experienced in producing alloy products, and has the detailed solutions for every customer, which the service is personalized for clients.

Alloy Applications

Alloys are crucial due to their superior properties compared to pure metals, such as enhanced strength, hardness, and corrosion resistance. They are widely used in aerospace, automotive, electronics, and construction, driving technological advancements and improving the efficiency and durability of various products. Huaxiao Metal Supplier provides the alloy products for sale, and welcome to inquiry and ask for the lastest price or the informations about the alloy industries.

Alloy Applications in Aerospace

- Aerospace Industry:

- Aluminum Alloys: Lightweight yet strong, these alloys are crucial for aircraft fuselages, wings, and other structural components, reducing fuel consumption and enhancing aircraft performance.

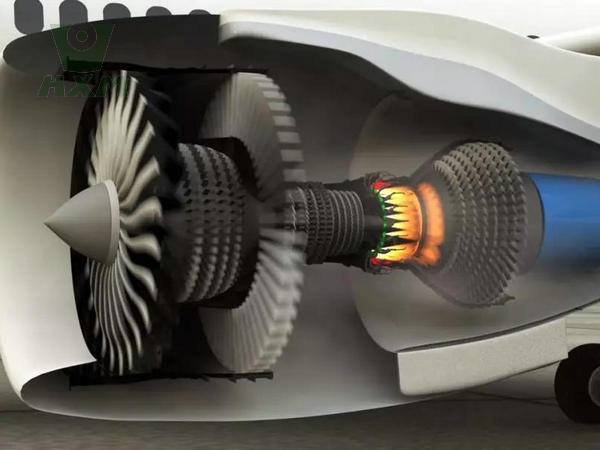

- Titanium Alloys: Known for their high strength-to-weight ratio, corrosion resistance, and ability to operate at high temperatures, titanium alloys are used in jet engines, landing gear, and other critical aerospace components.

- Nickel-Based Superalloys: These alloys are resistant to extreme temperatures and pressures, making them ideal for rocket engines and turbine blades.

Alloys play a pivotal role in the aerospace industry. Advanced aluminum alloys, for instance, have been a driving force in this sector, fulfilling the need for economical, low-density materials with high strength, damage tolerance, and durability. Over the years, high-strength aluminum alloy products have been the preferred choice for aircraft construction due to their ease of manufacture through low-cost processes and reliability. Additionally, aluminum-lithium alloys have been developed, with lithium reducing the density of aluminum alloys by 3% per 1% addition, while increasing modulus by 6%, making them highly valued in aerospace applications. In summary, alloy wires are indispensable in the aerospace industry, enabling the creation of lightweight yet durable aircraft components.

Alloy Applications in Automotive Industry

- Automotive Industry:

- Steel Alloys: High-strength steel alloys are used in vehicle frames, bumpers, and other safety-critical components to improve collision safety and overall structural integrity.

- Aluminum Alloys: Lightweight aluminum alloys are increasingly being used in car bodies, engines, and transmissions to reduce vehicle weight and improve fuel efficiency.

- Magnesium Alloys: Even lighter than aluminum, magnesium alloys are used in interior components and some structural parts to further reduce vehicle weight.

Alloys play a crucial role in the automotive industry, enhancing the performance and efficiency of vehicles. Aluminum alloys, for example, are widely used in engine blocks, transmissions, and body structures due to their lightweight properties and corrosion resistance. Magnesium alloys, another lightweight option, contribute to fuel efficiency by reducing overall vehicle weight. Meanwhile, steel alloy plates offer strength and durability, critical for safety components such as crumple zones and frame structures. These alloys, combined with innovative manufacturing techniques, allow automakers to create vehicles that are both safe and environmentally friendly.

Alloy Applications in Welding Industry

- Energy Industry:

- Nickel-Chromium-Iron Alloys: These alloys are used in nuclear reactors and other high-temperature applications due to their resistance to creep and stress relaxation.

- Aluminum-Silicon Alloys: Used in solar cells and photovoltaic panels, these alloys provide a lightweight and durable substrate for the solar cells.

- Copper-Nickel Alloys: These alloys are used in desalination plants and other marine applications due to their corrosion resistance and resistance to biofouling.

Alloys play a significant role in the welding industry, offering a wide range of materials suitable for various welding processes. Nickel alloy coils, known for their high temperature strength and corrosion resistance, are extensively used in welding applications in the chemical, petroleum, and energy industries. Aluminum alloys, due to their lightweight and corrosion-resistant properties, are also popular in welding for automotive and aerospace components. Furthermore, copper and copper-based alloys, with their excellent electrical and thermal conductivity, are often welded in the electrical and electronic industries. The versatility of alloys in welding makes them indispensable in creating strong, durable welds across multiple industries.

In Conclusion

Alloys, which are mixtures of metallic elements with one or more metallic or non-metallic elements, have found widespread applications across various industries due to their enhanced physical and chemical properties compared to pure metals. Alloys play a vital role in modern society, enabling advancements in technology, efficiency, and safety across a wide range of industries. Their diverse applications demonstrate the importance of alloy development and the continuous innovation required to meet the evolving needs of various sectors. Welcome to ask for the lastest price.